Method for laboratory treatment of high-temperature h2s/co2 mixed tail gas

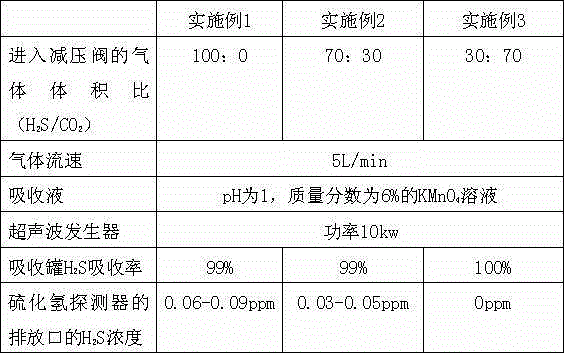

A CO2, laboratory technology, used in the field of laboratory treatment of high temperature mixed exhaust gas containing H2S/CO2, to achieve the effects of convenient use, improved exhaust gas treatment efficiency, safety and reliability, and stable product chemical state

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

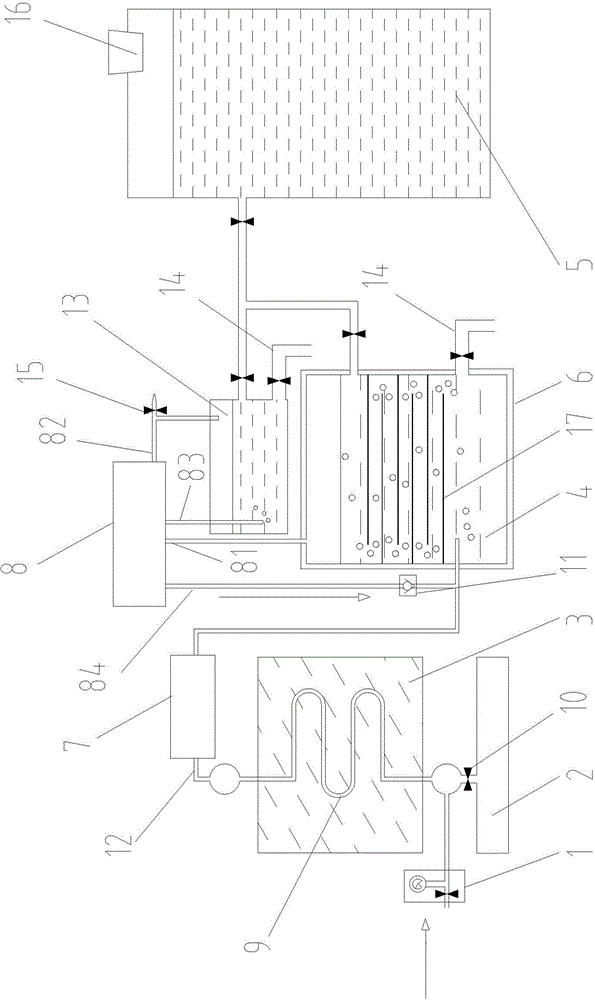

[0023] see figure 1 . For laboratory processing high temperature containing H 2 S / CO 2 The exhaust gas mixing device, the condenser 9 with the condensed water collector 2 is respectively connected to the inlet end of the flow controller 7 and the pressure reducing valve 1 through the pipeline 12, the middle section of the condenser is located in the cooling pool 3, and the condensed water collector A control valve 10 is arranged on the connecting pipe with the condenser. The condenser and the condensed water collector can be detachably connected, and can be connected by thread, clamping, etc., which is convenient for timely replacement. That is, if the cooling water in the condensed water collector is too full, close the condensed water collector and the condenser pipe. The control valve can quickly replace the empty condensate collector, and the replaced condensate collector continues to collect condensate. The exhaust end of the flow controller 7 is connected with the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com