Device and method for loading a transporting unit

A technology of transportation devices and equipment, applied in the field of equipment, can solve the problems of releasing operating force without increasing power, and achieve the effect of improving work comfort, high work comfort, and comfortable unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

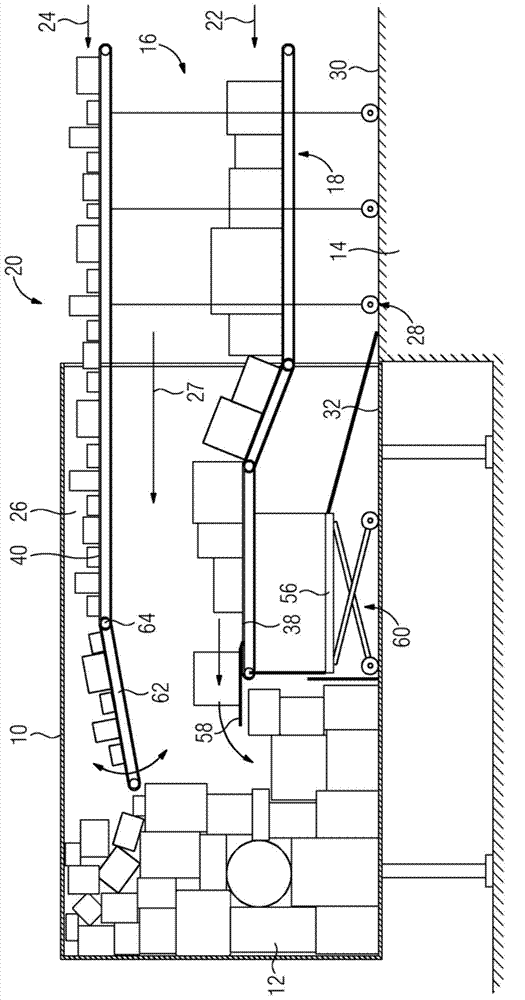

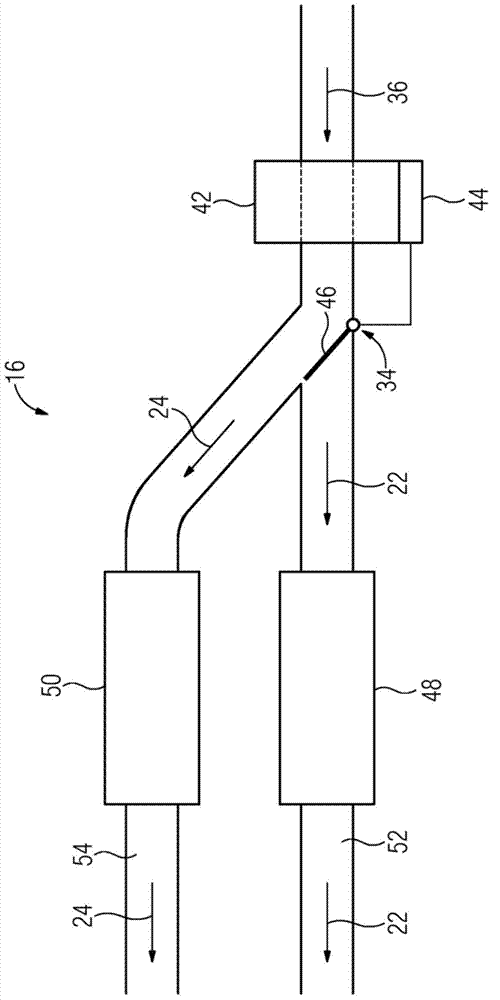

[0029] figure 1 Schematic representation of the design as a truck trailer (LKW- ) or a layout in which the transportation device 10 of the rotating container and the sorting center 14 are in a docking position, and it is used to transport the less-than-truckload goods 12 as postal items, especially postal parcels. To load the transport device 10 with part-load goods 12 , a device 16 is used which has two different transfer units 18 , 20 which are used to transfer and unload a part-load goods flow 22 or 24 into the transport device 10 .

[0030]The conveying units 18 , 20 can be driven together into the effective space 26 of the transport device 10 in a drive-in direction 27 , which corresponds in particular to the longitudinal direction of the transport device 10 . In the illustrated embodiment, the transfer units 18 , 20 are coupled to each other as mechanically associated assemblies having a running gear 28 which may be at the bottom 30 of the sorting and distribution cent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com