Structure and continuous stamping and automatic overlapping and assembling method of silicon steel sheets of transformer iron core of welding machine

A transformer core and silicon steel sheet technology, which is applied in transformer/inductor magnetic core, transformer/inductor parts, inductor/transformer/magnet manufacturing, etc., can solve the problem of low utilization rate of silicon steel sheet, large material waste, and low cost and other issues to achieve the effect of increasing market competition, low manufacturing cost, high speed and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

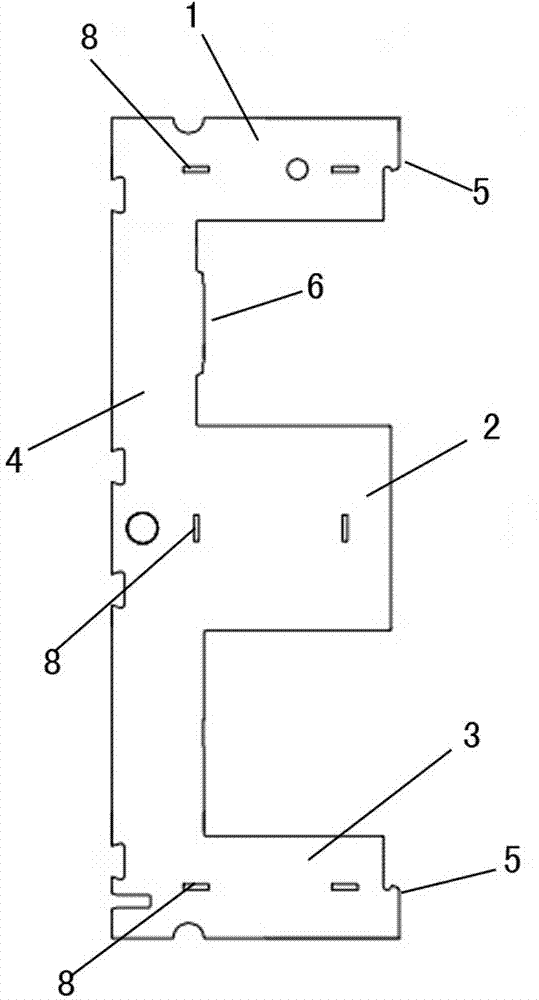

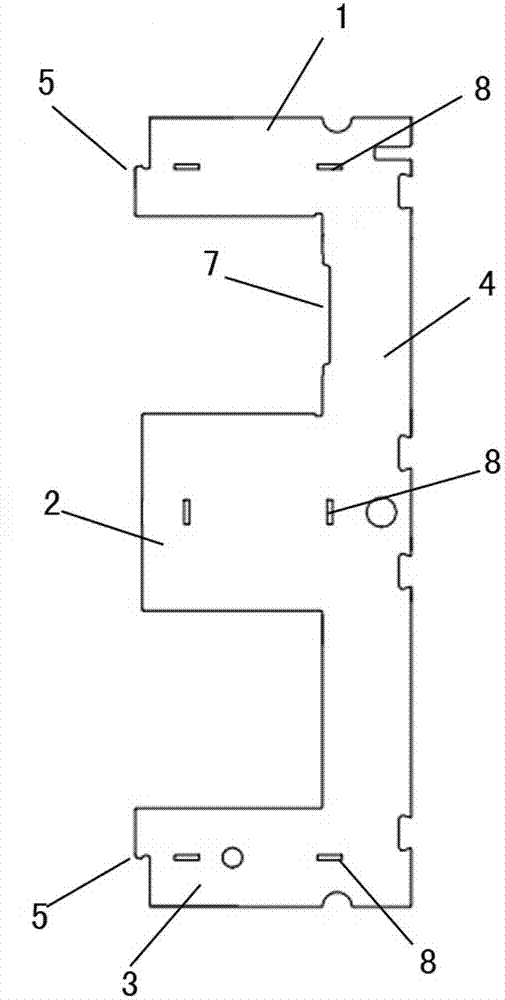

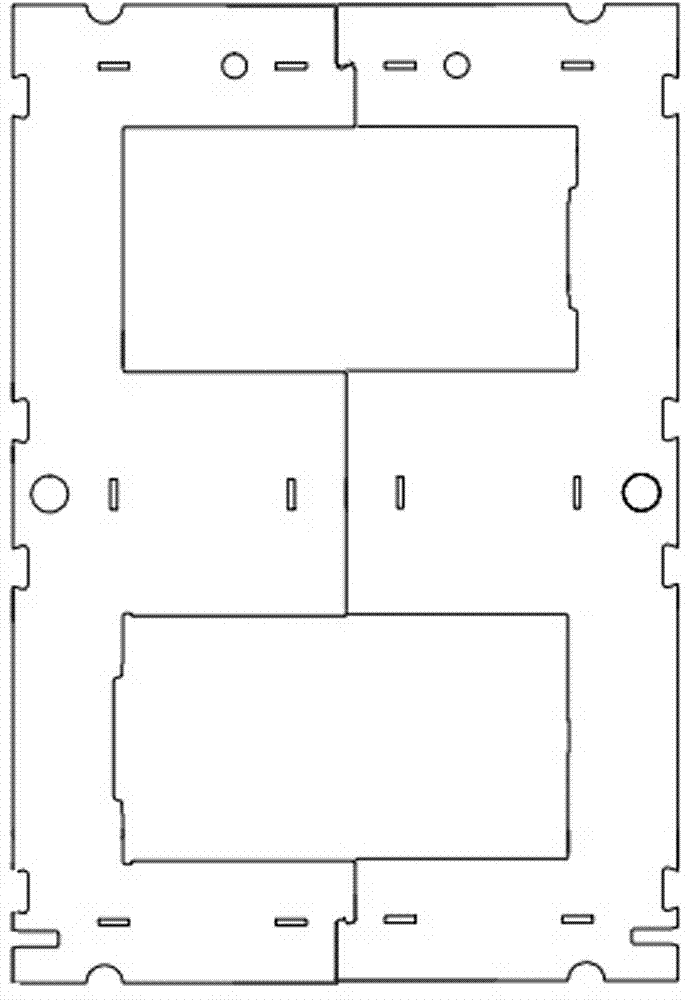

[0025] Such as Figure 1-2As shown, a welding machine transformer iron core silicon steel sheet structure, including E-type sheet and reverse E-type sheet, each E-type sheet and reverse E-type sheet includes upper yoke 1, middle yoke 2, lower yoke 3 and side Yoke 4, the height of the upper yoke 1 and the lower yoke 3 is half of the distance between the upper yoke 1 and the middle yoke 2 or the distance between the lower yoke 3 and the middle yoke 2. The opposite edges of the upper yoke and the lower yoke are provided with buckling parts 5 that can cooperate with each other, such as image 3 As shown, the E-shaped sheet and the reverse E-shaped sheet can be spliced through the fastening part 5 to form a double "mouth"-shaped sheet; a flange 6 or a groove is also provided on the rib of the E-shaped sheet and the reverse E-shaped side yoke 4 7. When several E-type pieces and reverse E-type pieces are plugged together and combined together, the fastening parts of the upper and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com