Polarizing LED (Light-Emitting Diode) display screen based on polarizing film and method for forming polarizing film

A technology of LED display screen and molding method, applied in installation, optics, instruments, etc., can solve problems such as reducing the display viewing angle, and achieve the effect of increasing the display viewing angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings by means of specific embodiments:

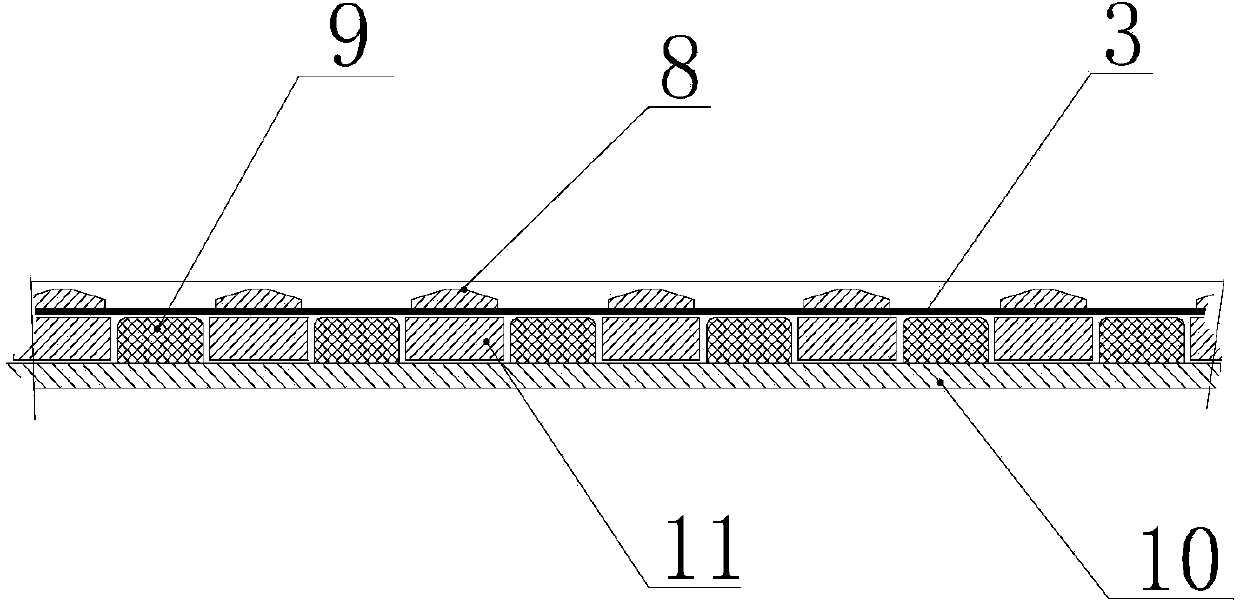

[0025] Such as figure 1 As shown, the existing polarizing film 3 for large-screen display is placed or pasted on the LED device 9, the LED device 9 is installed on the PCB board 10, there is a substrate 11 between the LED devices, and then on the polarizing film 3 Install a hood 8 (or lampshade, sunshade, isolation cover, etc.). In this way, due to the location problem of the polarizing film, the light shield is obviously higher than the polarizing film, which reduces the display viewing angle.

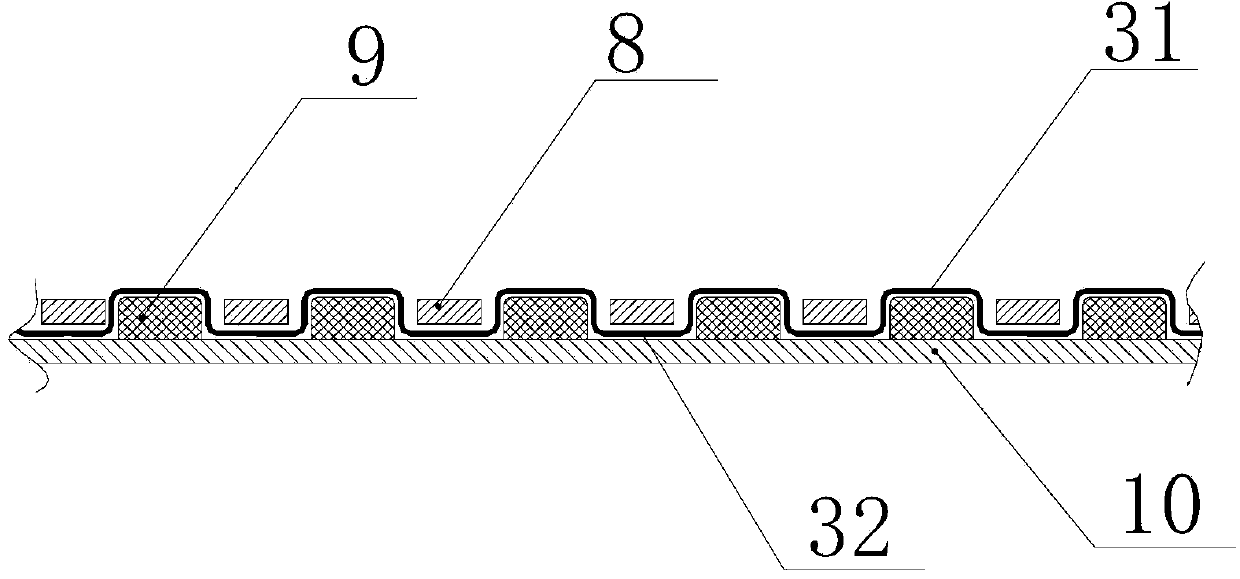

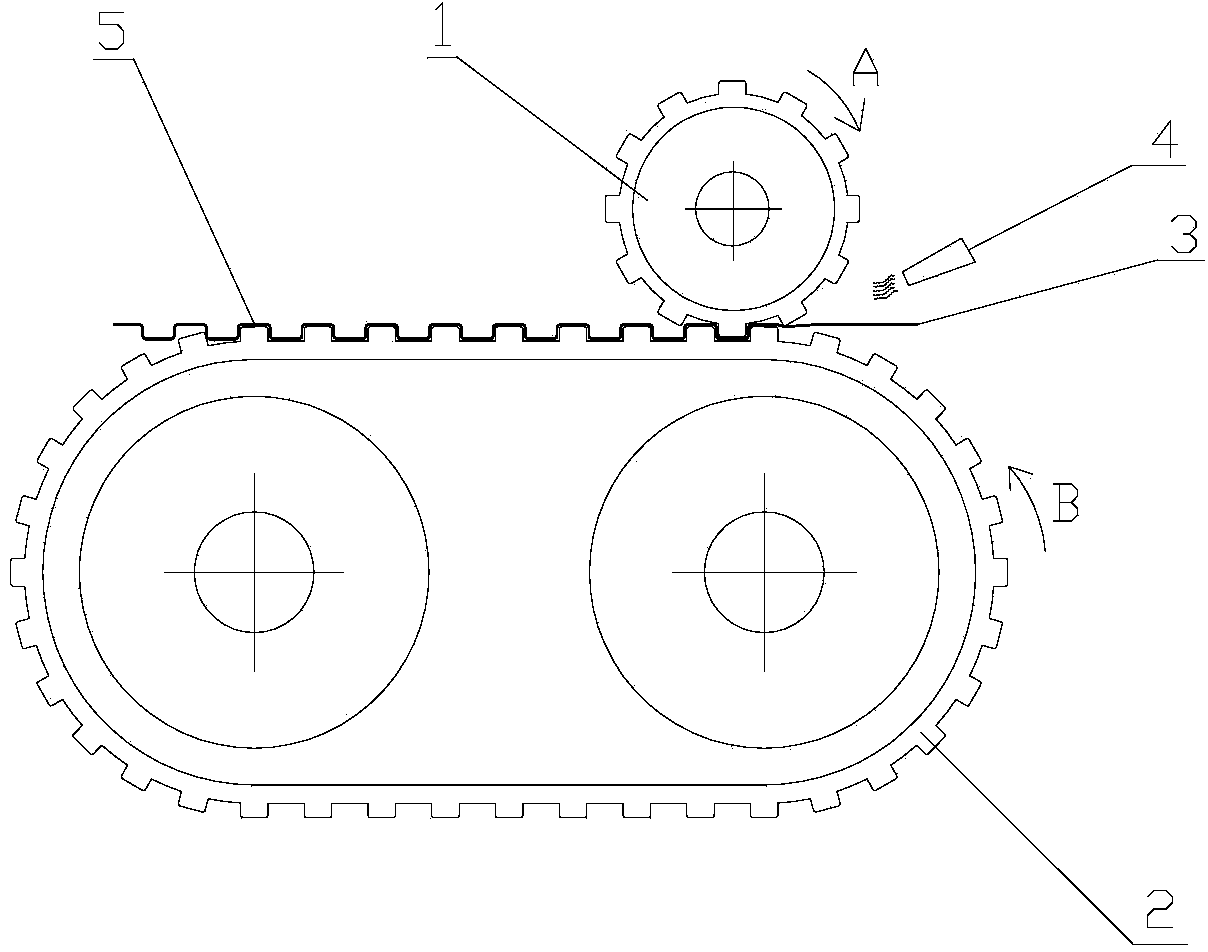

[0026] Such as figure 2 Shown is a cross-sectional schematic view of the final drive circuit board with polarizing film placed in the present invention. LED light-emitting device 9 is arranged on PCB board 10. Polarizing film 3 is processed into a concave-convex strip structure by molding machine. Polarizing film 3 is made of conve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com