A test terminal assembly for electric energy metering

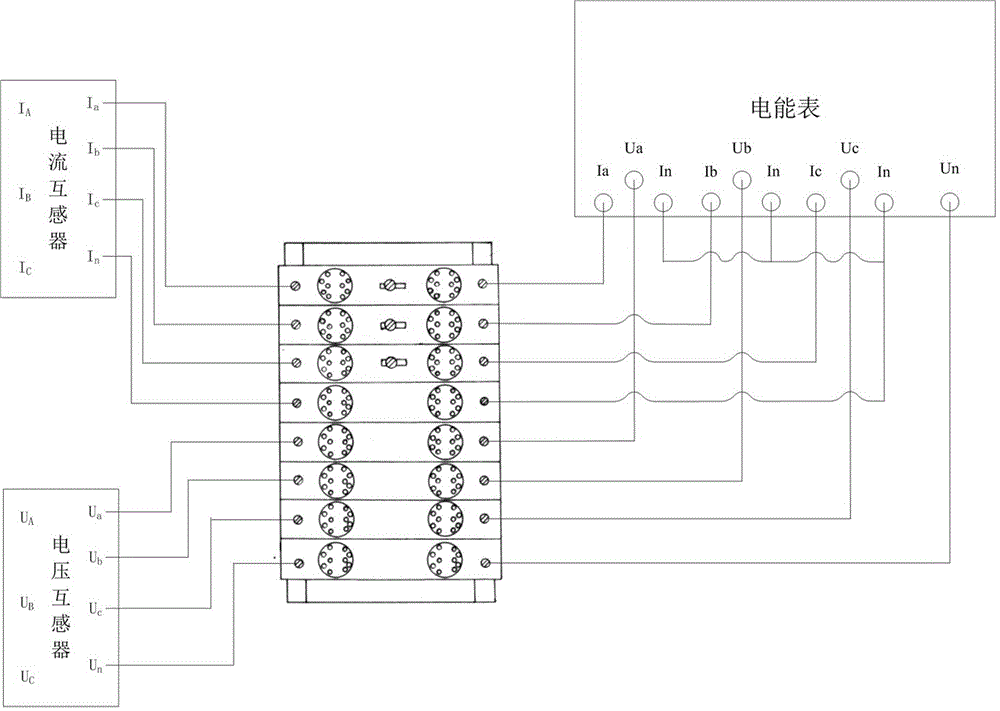

A technology for testing wiring and terminal assemblies, which is applied in the direction of measuring electrical variables, measuring devices, and measuring time integration. Secondary circuit open circuit and voltage secondary circuit short circuit or grounding accident, eliminate the effect of voltage secondary circuit short circuit or grounding accident, and avoid voltage secondary circuit loss of voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

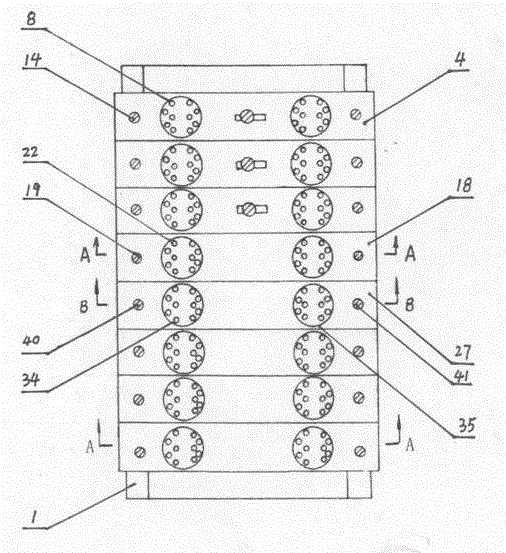

[0051] Depend on Figure 1-11 As can be seen from the illustrated embodiment, this embodiment includes a pallet 1 with guide rails on the left and right sides, A-C phase current connection terminals, zero-phase current connection terminals, A-C phase voltage connection terminals, zero-phase voltage connection terminals, the first plug and the second Two plugs; the connecting terminals are sequentially installed on the guide rail of the pallet 1;

[0052] The A-phase current connection terminal includes a first terminal insulating body 4, two first cylindrical sockets, a metal sliding piece 5 and two first metal conductors 6;

[0053] The inside of the first terminal insulating body 4 is provided with left and right first cavities 7, and the two first metal conductors 6 are respectively located in the two first cavities 7, and are connected to the first cavities respectively. One chamber 7 is matched; the upper part of the first terminal insulating body 4 is provided with firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com