Heat exchanger flow equalizer

A heat exchanger and equalizing plate technology, which is applied to the heat exchanger shell, heat exchange equipment, lighting and heating equipment, etc., can solve the problem that the heat exchanger cannot be designed with a split air duct structure, restrict the split air duct structure, and take up space. Large and other problems, to achieve the effect of small occupied space, simple structure design, and improved use efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

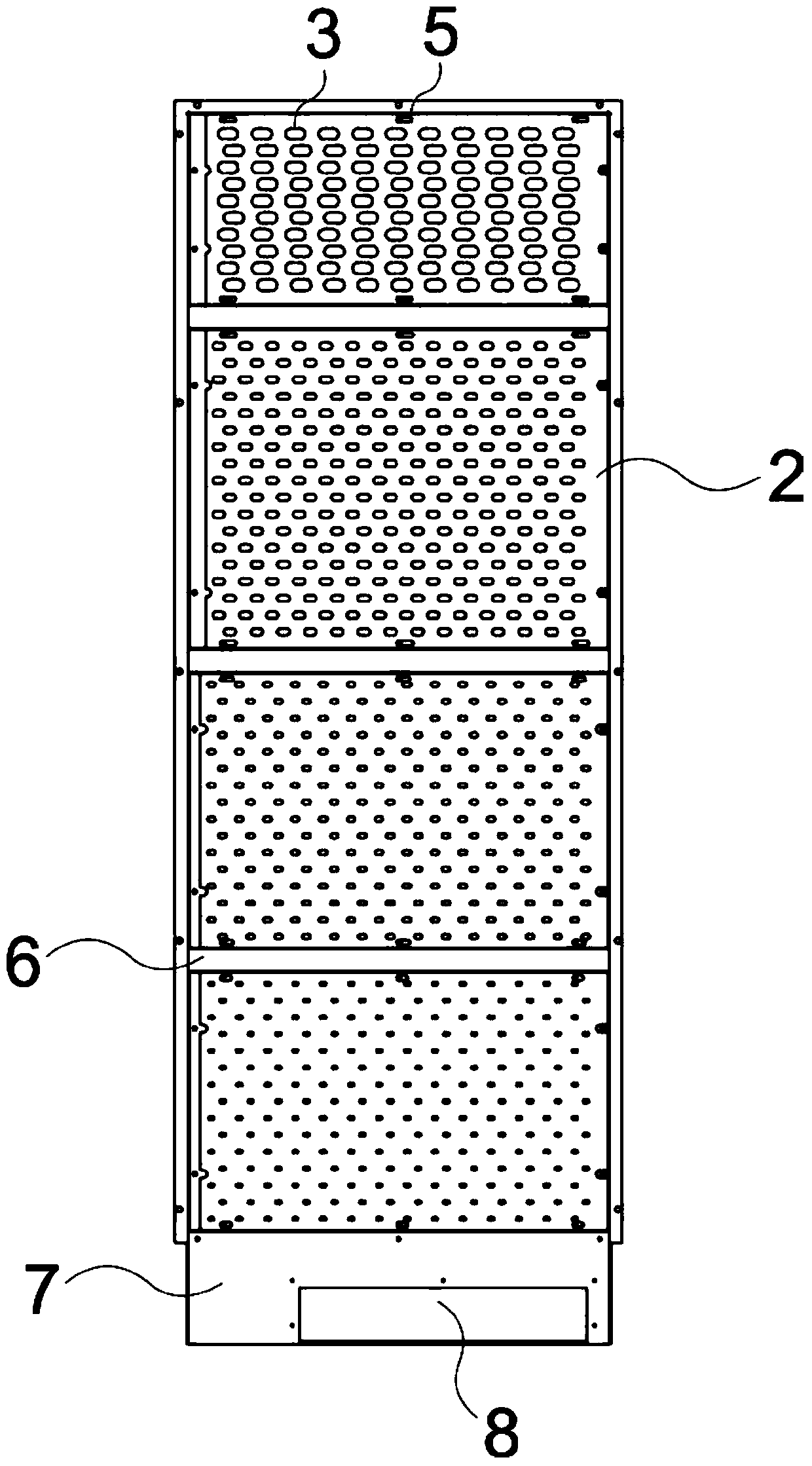

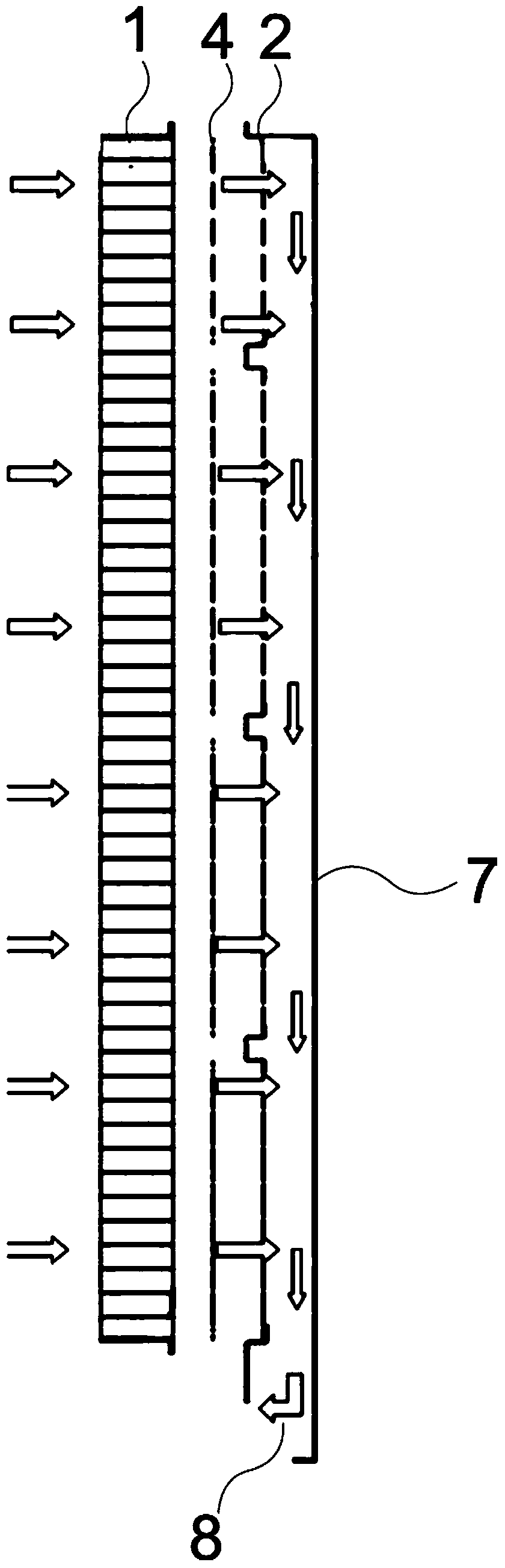

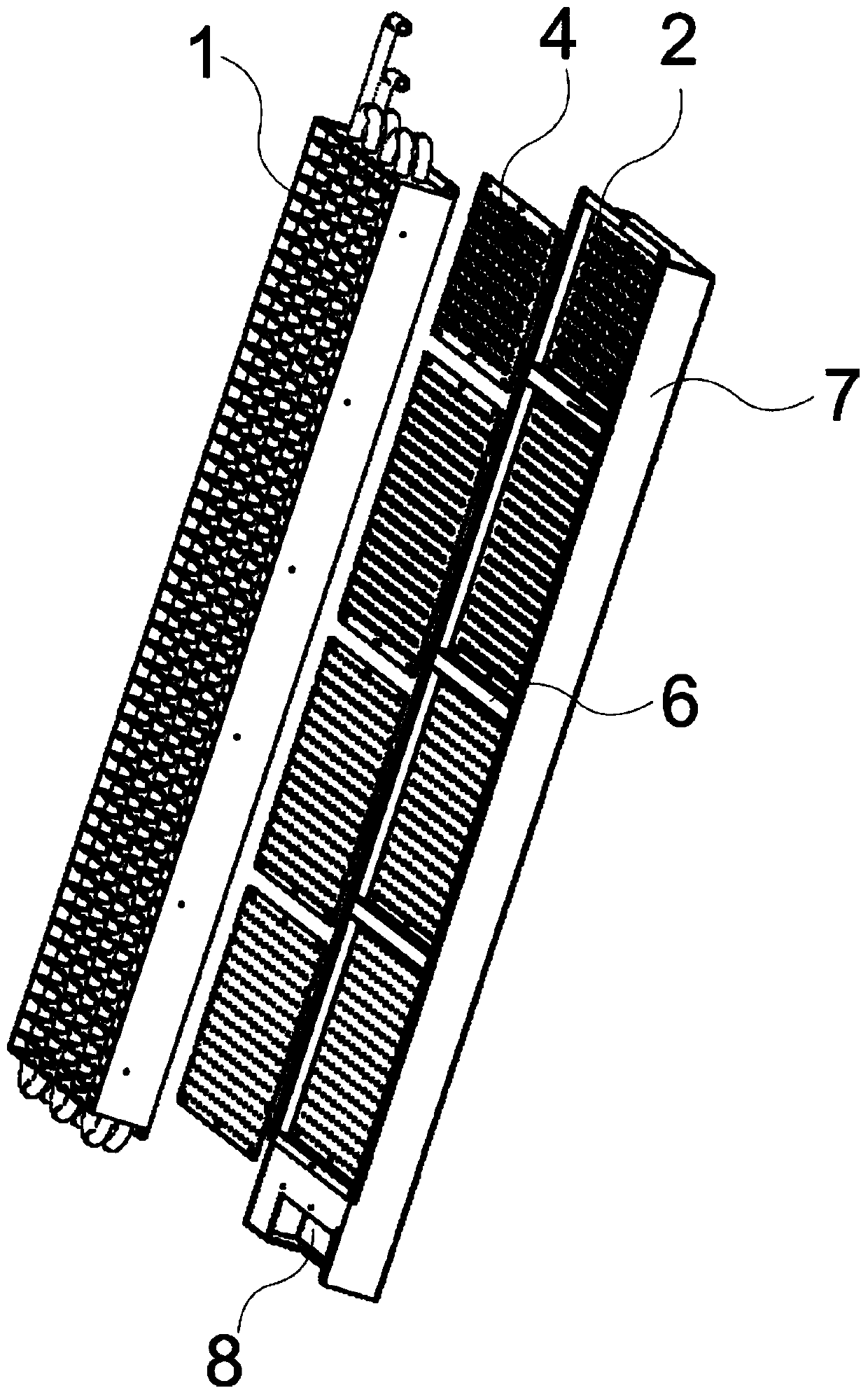

[0028] Combine below Figure 1 to Figure 6 A kind of heat exchanger flow equalizing device among the present invention is described further:

[0029] The fluid inside the microenvironment of semiconductor equipment is generally nitrogen or air, such as figure 2 As shown, the left side of the heat exchanger 1 is the air inlet side, and the right side of the heat exchanger 1 is the air outlet side. When the heat exchanger 1 has no flow equalization device, since the air outlet 8 is located on the lower side of the return air box 7, The air pressure of the air duct inside the return air box 7 is different, resulting in the flow of fluid passing through the lower side of the heat exchanger 1 much greater than the flow rate passing through the upper side of the heat exchanger 1, reducing the use efficiency of the heat exchanger.

[0030] Such as Figure 1 to Figure 4 As shown, a heat exchanger flow equalization device provided by the present invention includes a heat exchanger 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com