Prefabricated buried steam heat-preservation pipe with high heat preservation performance

A steam thermal insulation pipe, prefabricated direct burial technology, applied in the direction of thermal insulation, pipeline protection through thermal insulation, pipeline protection, etc., can solve the problems of affecting gas transmission and heating efficiency, increasing cost input, limited transmission distance, etc., to reduce heat The effect of consumption, increasing conveying distance and reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

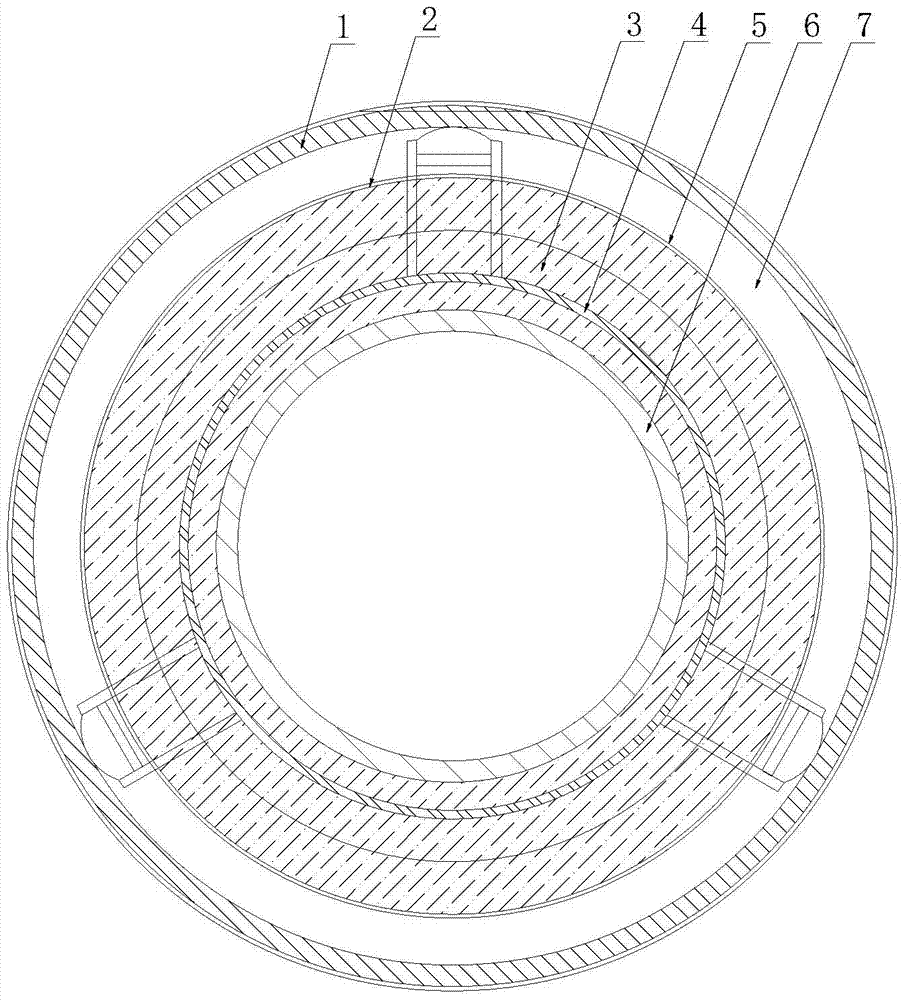

[0011] A prefabricated direct-buried steam insulation pipe with high thermal insulation performance is composed of a working steel pipe 6, an insulation layer, a rolling support 4, and an outer protective steel pipe 1 in sequence from the inside to the outside. The hoop of the rolling support is on the working steel pipe, and an air layer 7 is formed between the insulation layer and the outer protecting steel pipe; the outer surfaces of the working steel pipe and the outer protecting steel pipe are all shaped with anticorrosion layers. The insulation layer is made of aluminum foil reflective cloth 2 and nano-insulation material (DR06) 3; the outer layer of the insulation layer is wrapped with glass wool and glass fiber cloth 5 to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com