Electro-hydraulic system for energy recovery and release of slewing brake of construction machinery

A technology for construction machinery and energy recovery, which is applied to fluid pressure actuation system components, mechanical equipment, fluid pressure actuation devices, etc. The control of the signal is convenient, the efficiency is improved, and the energy saving effect is remarkable.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

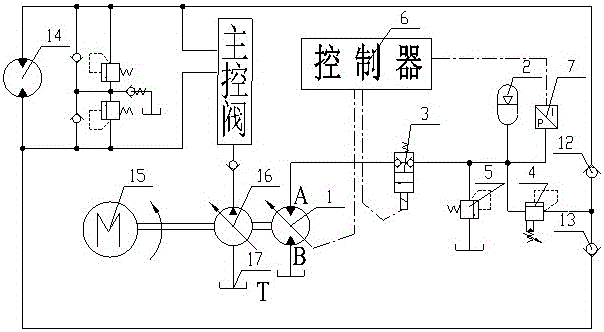

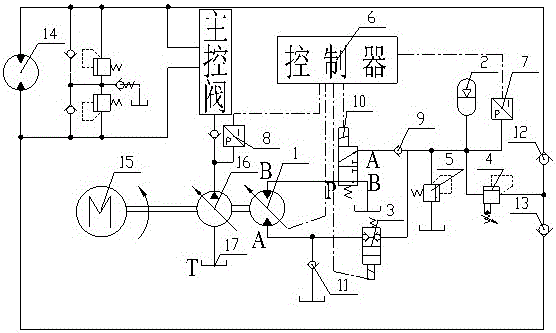

[0022] In the present invention, engineering machinery refers to excavating machinery, earth shoveling machinery, full-rotation pile pulling machinery and other construction machinery used in engineering construction with frequent rotary motions.

[0023] figure 1 A working principle diagram of an electro-hydraulic system with a structure of the present invention is shown. like figure 1 As shown, the electro-hydraulic system of the present invention mainly includes an energy recovery and release mechanism and a control unit, wherein the control unit includes a controller 6 and a first pressure sensor 7, and the energy recovery and release mechanism includes a hydraulic energy storage unit 2, a first electromagnetic transducer Directional valve 3, hydraulic motor 1, sequence valve 4, first one-way valve 12 and second one-way valve 13. The hydraulic motor 1 is coaxially connected with the main variable pump 16 of the construction machinery, the A port of the hydraulic motor 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com