Leather product window edge folding machine

A technology of folding machine and window, applied in the trimming of leather edges, mechanical processing of small raw hides/large raw hides/leather/fur, small raw hides/large raw hides/leather/fur processing, etc., which can solve the problems of low efficiency and poor quality. Stability, strong technical dependence of finished product quality, etc., to achieve the effect of convenient maintenance, small footprint, and reliable folding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

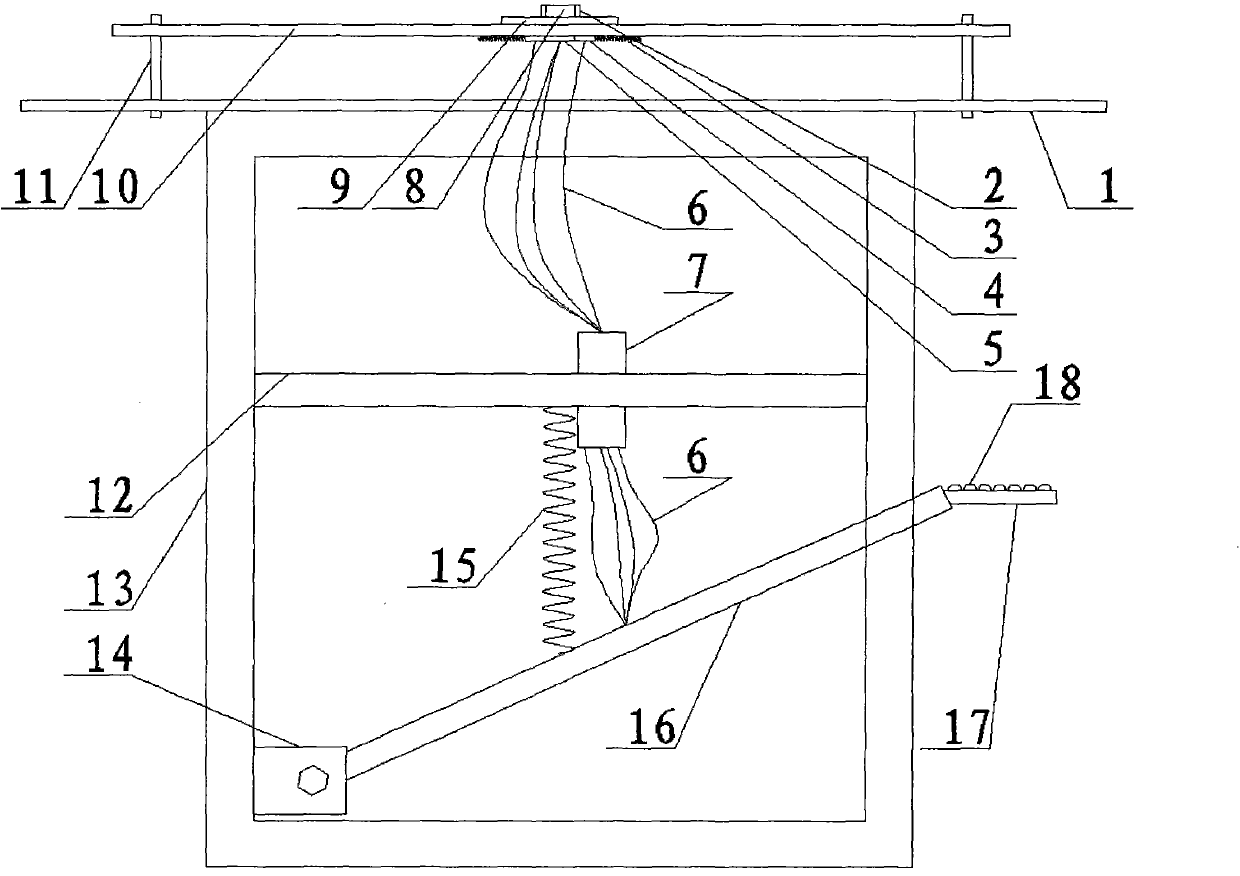

[0018] figure 1 A specific embodiment of the present invention is shown. The leather window folding machine of the present invention is used for folding the zipper window of leather goods. The zipper window is a rectangular structure with two narrow sides and two wide sides, including A panel 1 with a window in the center and a support leg 13 supporting the panel 1, on which a tie rod 12 is arranged; also includes a hemming assembly and a pedal assembly for driving the hemming assembly to complete the hemming action;

[0019] The hemming assembly includes a wide-side hemming assembly and a narrow-side hemming assembly; the panel 1 fixes a plane upper and lower mold 10 by a screw 11, and a plane upper and lower mold 10 fixes a plane left and right mold 9, a plane upper and lower mold 10 and a plane left and right mold 9 A rectangular window larger than the size of the zipper window is formed at the overlapped place in the middle; the wide side and the narrow side of the rectang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com