Non-phthalate nitrile rubber material and preparation method thereof

A technology for phthalate nitrile-butadiene rubber and rubber material, which is applied in the field of non-phthalate nitrile-butadiene rubber material and its preparation, and achieves obvious social and economic benefits and excellent performance effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

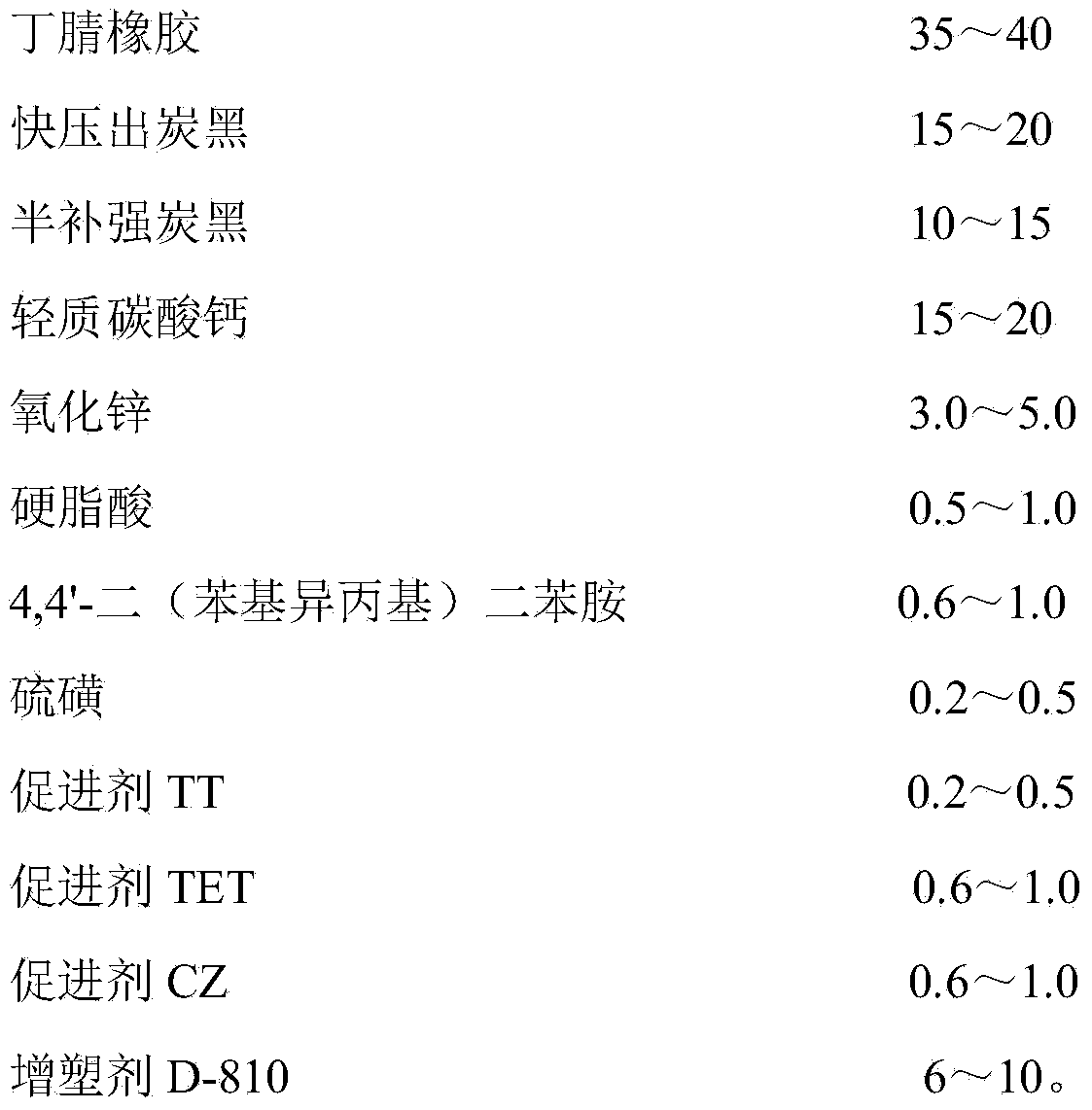

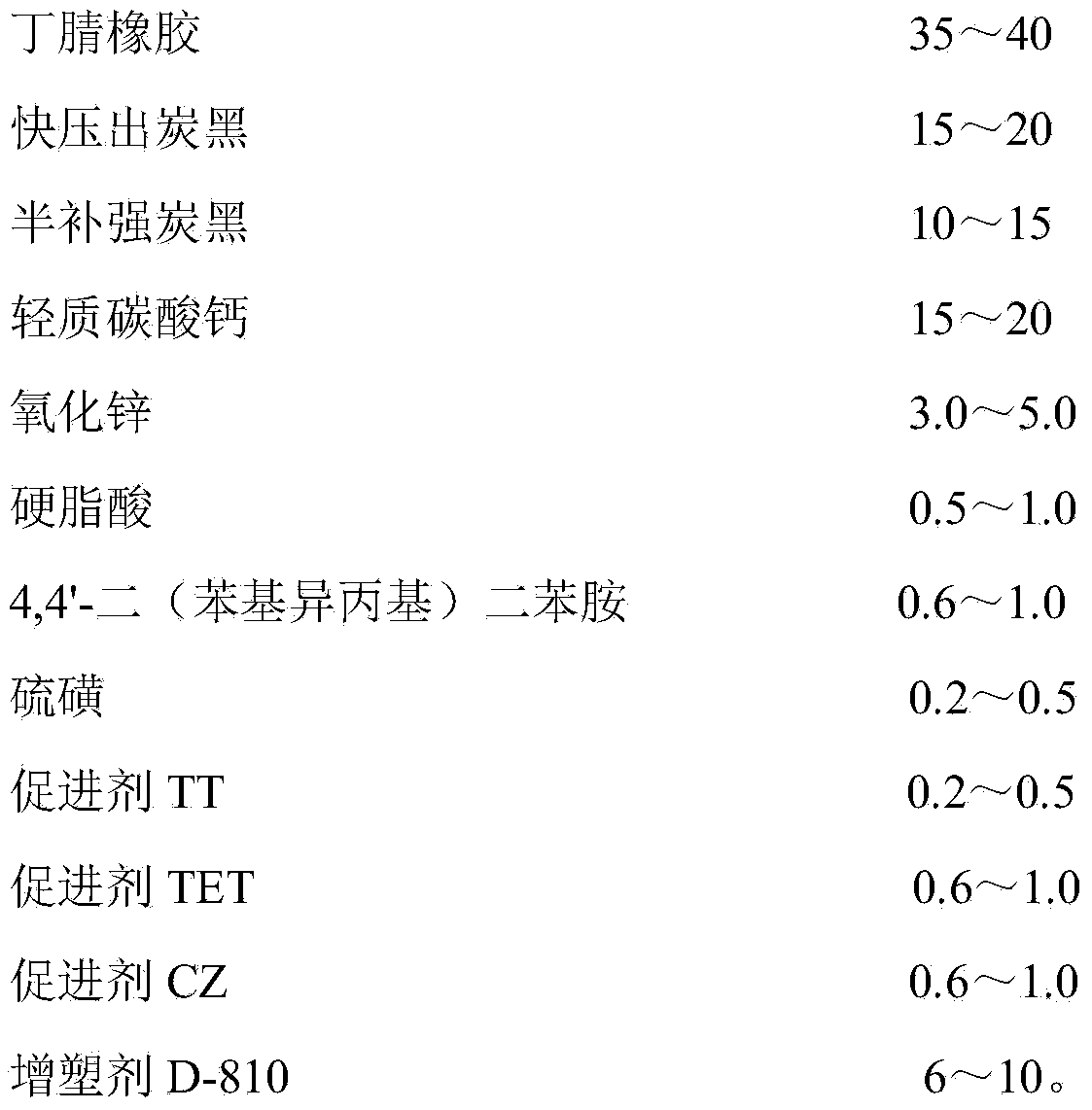

[0027] A non-phthalate nitrile rubber material in this embodiment is composed of the following components by weight percentage, see Table 1 for details. The plasticizer D-810 in this implementation is produced by Taiwan Changchun Chemical Group. The main performance parameters are: viscosity at 25°C is 55-65cps, acid value ≤ 0.1mgKOH / g, hydroxyl value ≤ 5.0mgKOH / g, The specific gravity at 25°C is 0.97-1.00, the refractive index at 25°C is 1.487-1.490, the moisture content is ≤0.1%, the color APHA≤20, and the volatile content is ≤0.2%. The plasticizer D-810 supplier in this implementation is Shanghai Huixin Chemical Co., Ltd.

[0028] Component and percentage content of non-phthalate nitrile rubber material in table 1 embodiment 1

[0029] Component name

Weight percentage / %

Nitrile rubber

37

quick press carbon black

18

semi-reinforcing carbon black

12

18

4

stearic ac...

Embodiment 2

[0040] A non-phthalate nitrile rubber material in this embodiment is composed of the following components by weight percentage, see Table 2 for details.

[0041] Component and percentage content of non-phthalate nitrile rubber material in table 2 embodiment 2

[0042] Component name

Weight percentage / %

Nitrile rubber

40

quick press carbon black

15

semi-reinforcing carbon black

10

19

3

0.5

4,4'-Bis(phenylisopropyl)diphenylamine

0.6

0.3

Accelerator TT

0.3

Accelerator TET

0.7

Accelerator CZ

0.6

Plasticizer D-810

10

[0043] The manufacturer of each component in this implementation and performance parameter thereof are with embodiment 1, adopt the above-mentioned non-phthalate nitrile rubber material formula of the present embodiment, and the step of its preparation method is:...

Embodiment 3

[0050] A non-phthalate nitrile rubber material in this embodiment is composed of the following components by weight percentage, see Table 3 for details.

[0051] Component and percentage content of non-phthalate nitrile rubber material in table 3 embodiment 3

[0052] Component name

Weight percentage / %

Nitrile rubber

35

quick press carbon black

20

semi-reinforcing carbon black

15

light calcium carbonate

16

Zinc oxide

5

0.5

4,4'-Bis(phenylisopropyl)diphenylamine

1.0

0.5

Accelerator TT

0.5

Accelerator TET

0.5

Accelerator CZ

1.0

Plasticizer D-810

5

[0053] The manufacturer of each component in this implementation and performance parameter thereof are with embodiment 1, adopt the above-mentioned non-phthalate nitrile rubber material formula of the present embodiment, and the step of its preparation method is: ...

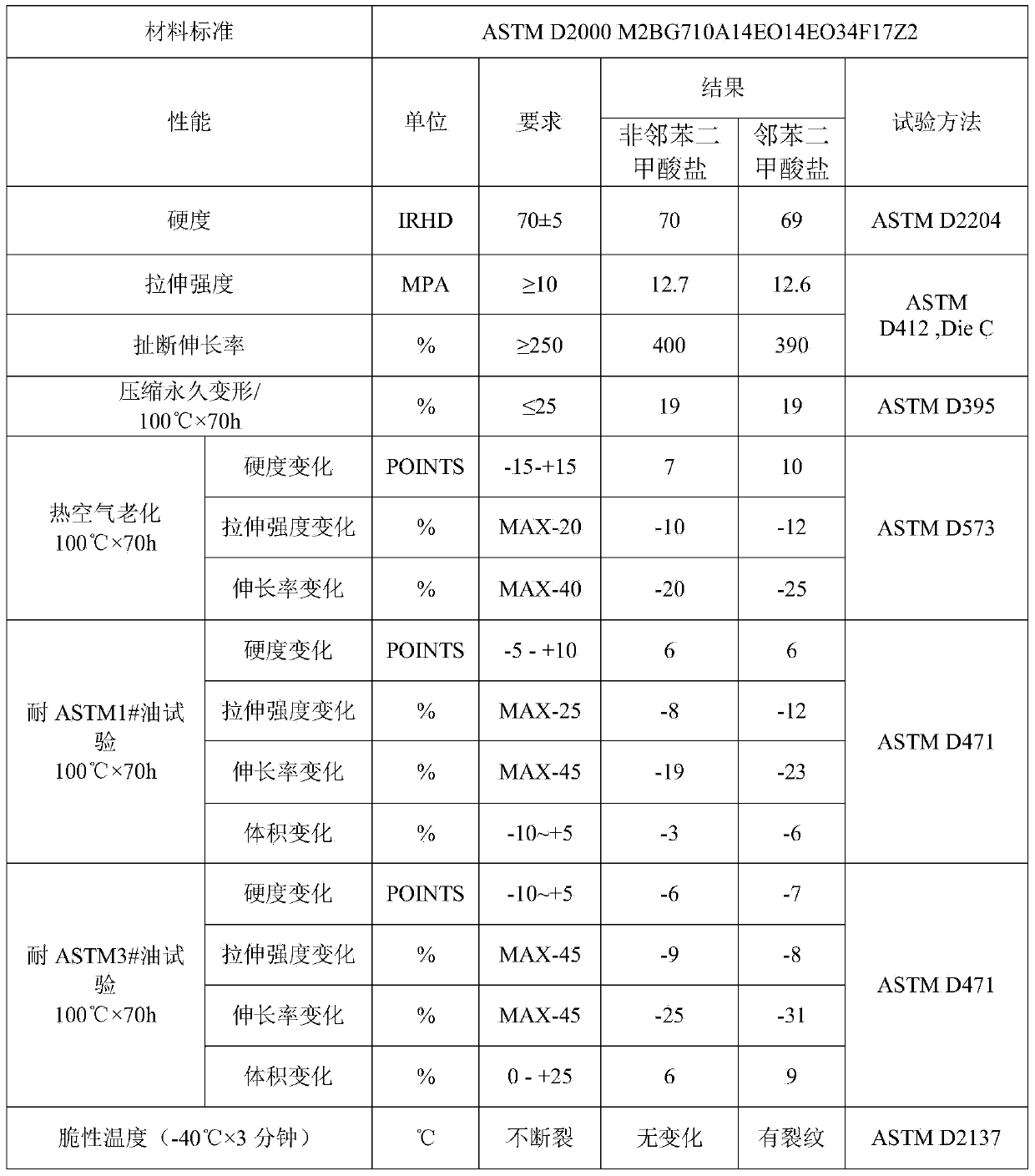

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com