Pin feeding system for surface mounting technology (SMT) chip mounter

A feeding system and placement machine technology, applied in the direction of mechanical conveyors, conveying bulk materials, conveyors, etc., can solve the problems of automatic feeding, slow speed, high cost, etc. The effects of batch automatic placement of pins, increased production rate, and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to fully understand the technical content of the present invention, the technical solutions of the present invention will be further introduced and illustrated below in conjunction with specific embodiments.

[0030] The concrete structure of the embodiment of the present invention is as Figure 1 to Figure 11 shown.

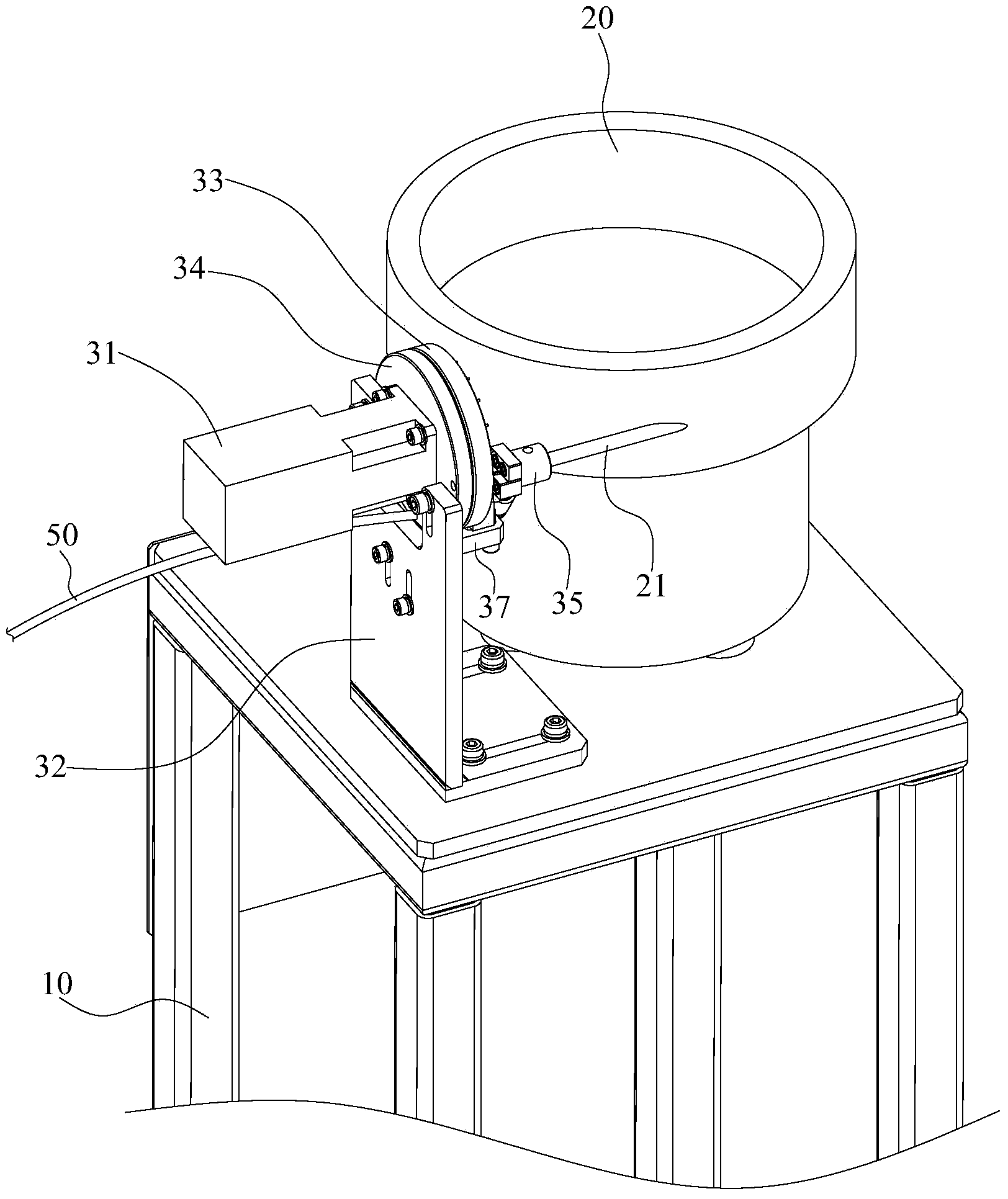

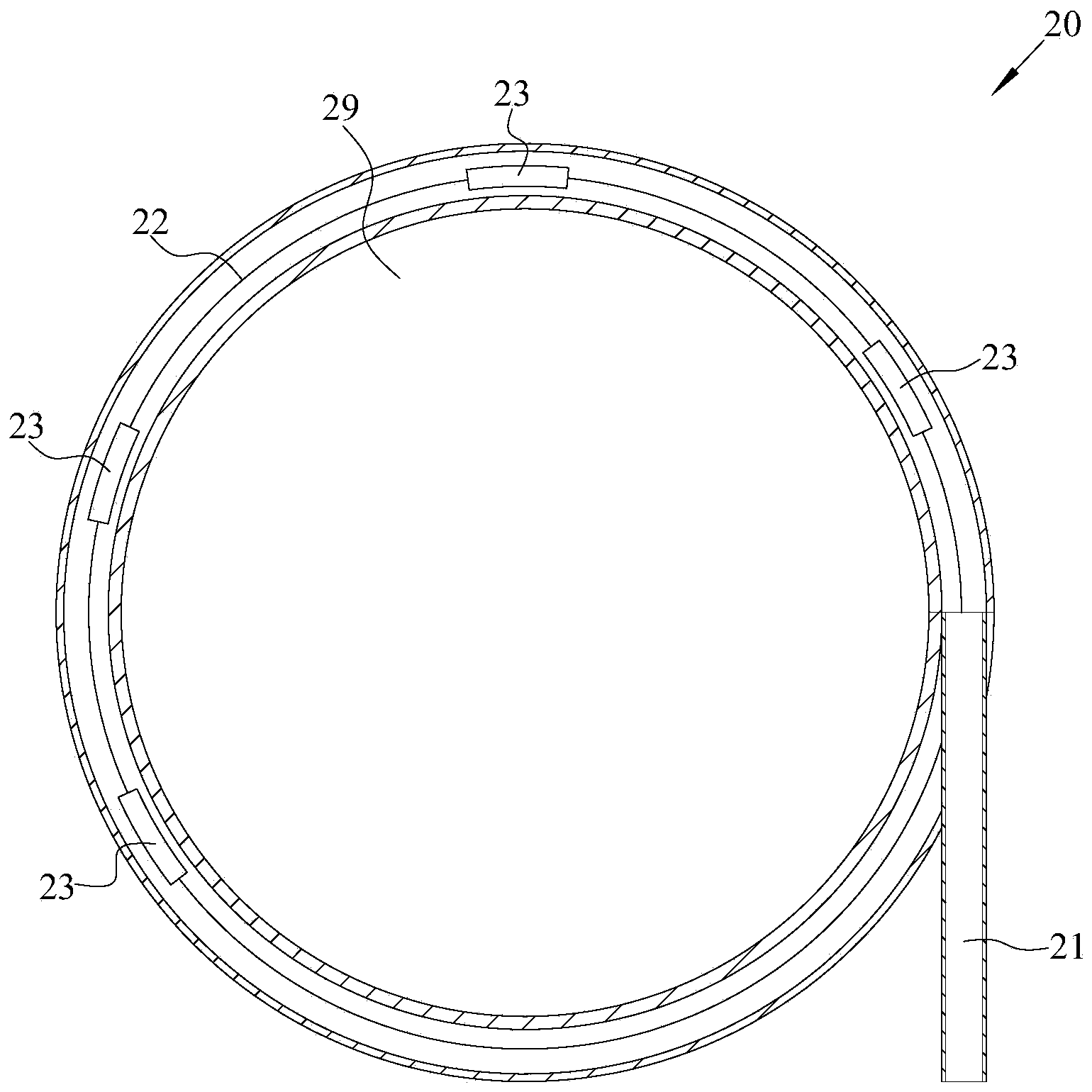

[0031] The pin 60 feeding mechanism includes a main control unit, a workbench 10, a vibrating plate 20 fixed on the workbench 10 for neatly arranging the scattered pins 60, for receiving the pins 60 to wait for the SMT placement machine to insert The material assembly 40 to be removed by the needle 60 and the material transfer assembly 30 for transferring the pin 60 from the vibrating plate 20 to the assembly 40 .

[0032] The concrete structure of material transfer assembly 30 sees Figure 2 to Figure 9 shown. The feeding assembly 30 is fixed on the workbench 10 . The material transfer assembly 30 includes a material storage disc 33, a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com