Rotary separation conveyor

A conveyor and rotary technology, applied in the field of rotary separation conveyors, can solve the problems of reducing the service life of the equipment, polluting the air, short conveying width, etc., and achieving the effect of increasing the conveying volume, reducing the moisture content of the garbage and reducing the friction force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

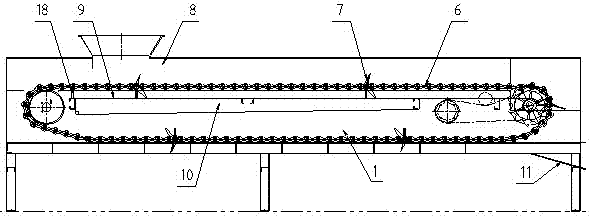

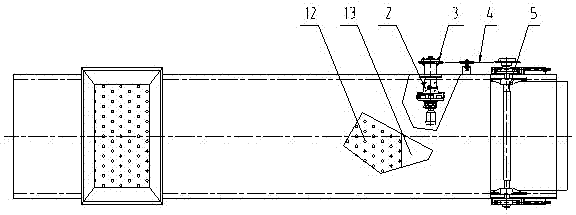

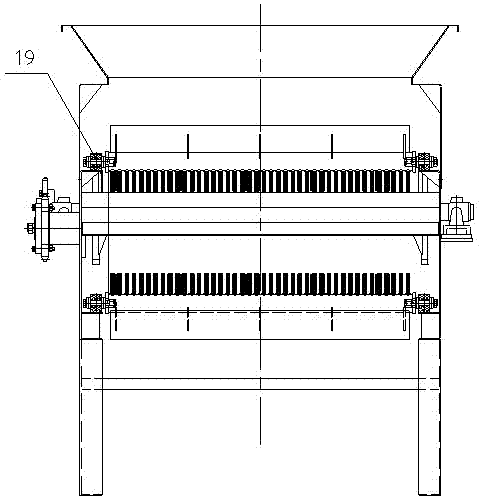

[0022] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] like figure 1 , figure 2 , image 3 and Figure 4 As shown, the rotary separation conveyor of the present invention includes a conveying frame 1, and a shaft-mounted geared motor 2 arranged inside the conveying frame 1, and a driving part 3 is connected to the output end of the geared motor 2, and the driving part 3. Connected with the transmission device 5 through the roller chain 4, the transmission device 5 drives the slag removal device 7 to run along the track through the transmission chain 6, and the dirt enters the conveying box through the material connection port of the odor-proof cover 8 and is discharged on the support On the plate 9, part of the water contained in the dirt enters the sump 10 through the holes of the supporting plate 9 due to gravity, and the sewage is transported to the relevant drainage system thr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap