Device with multiple packing machines sharing pipe sticking machine

A packaging machine and tube sticking machine technology, applied in the direction of packaging machines, packaging, transportation and packaging, etc., can solve the problems of large area occupation, repeated investment, waste of tube sticking machines, etc., to reduce investment costs, ensure continuity, improve The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

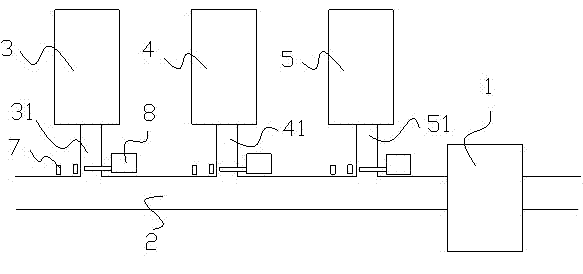

[0014] Such as figure 1 , The device for multiple packaging machines sharing the tube applicator of the present invention includes a conveyor belt 2 connected to the tube applicator 1, the discharge channel 31 of the packaging machine 3, the discharge channel 41 of the packaging machine 4, and the packaging machine 5 The discharge channel 51 is connected to the conveyor belt 2 at intervals. The connection between the discharge channel 31 of the packaging machine 3 and the conveyor belt 1 is provided with a sensor 7 for detecting whether the connection is sufficient for placing a packaging box. The discharging channel 31 is provided with a cutting device 8 controlled according to the signal of the sensor 7. The packaging machine 3, the packaging machine 4 and the packaging machine 5 are all located on the same side of the conveyor belt 2. This embodiment can be used when the width of the workshop where the packaging machine and the tube sticking machine are placed is insufficien...

Embodiment 2

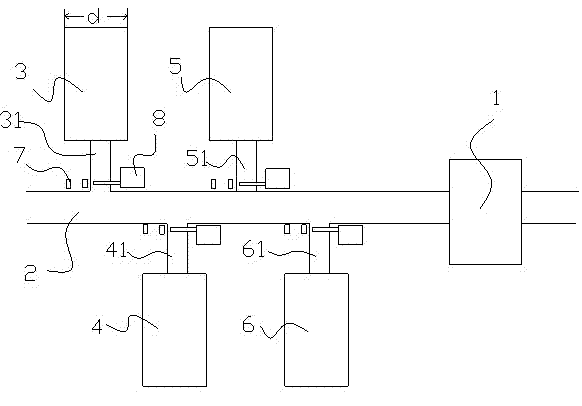

[0016] Such as figure 2 , Multiple packaging machines share the device of the tube applicator, including a conveyor belt 2 connected to the tube applicator 1, the discharge channel 31 of the packaging machine 3, the discharge channel 41 of the packaging machine 4, and the discharge channel of the packaging machine 5 51. The discharge channel 61 of the packaging machine 6 is connected to the conveyor belt 2 at intervals, and the connection between the discharge channel 31 of the packaging machine 3 and the conveyor belt 1 is provided with a sensor for detecting whether the connection is sufficient to place a packaging box. 7. The discharge channel 31 of the packaging machine 3 is provided with a cutting device 8 controlled by the signal of the sensor 7. The packaging machine 3, the packaging machine 4, the packaging machine 5, and the packaging machine 6 are arranged on both sides of the conveyor belt 2 at a cross interval. When the width d of the discharge channel of the pack...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com