Method and device for operating a machine tool such as a press

A technology of machine tools and presses, which is applied in the field of machine tools, can solve the problem that the press machine is not considered, and achieve the effect of energy optimization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

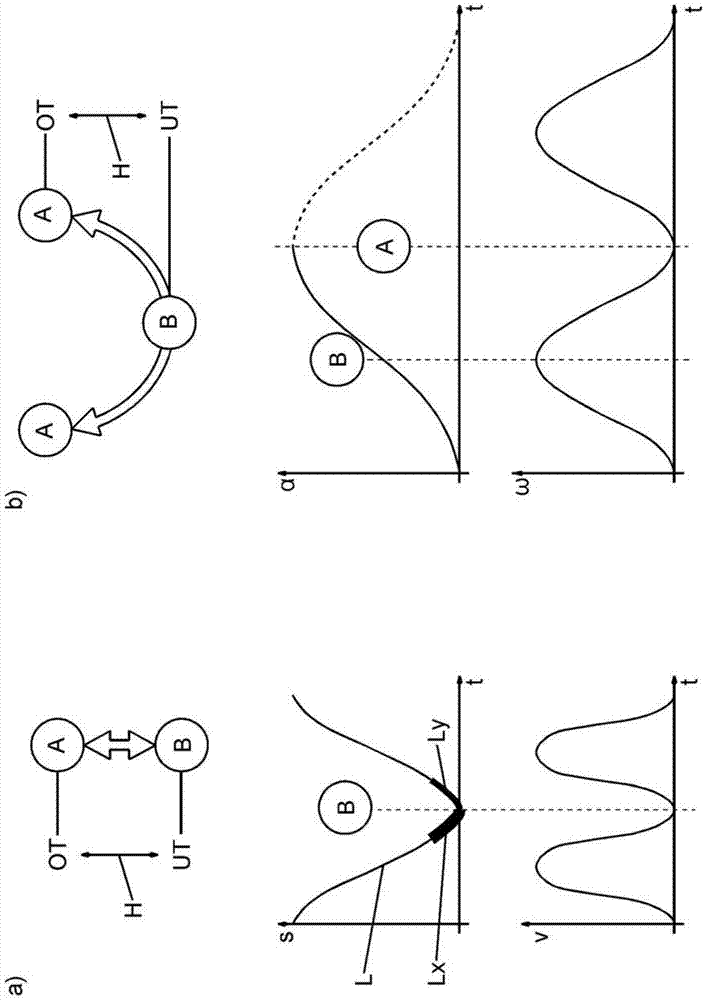

[0183] In order to graphically illustrate the initial situation of the problem solved by the present invention, it should first be based on figure 1 The principle of the linear movement form of the tappet slide and the rotary movement form of the drive is shown as a schematic principle of the movement form on a virtual example of a press with a lifter slide, to be precise, As in detail a) as a linear movement form of a stroke element such as a plunger not shown here and as in detail b) as a rotational movement form of a drive not shown here.

[0184] Symbolically and according to the role means:

[0185] A = start and end of movement

[0186] ■ In rotary moved units such as drives: stationary state (detail b))

[0187] ■In units with linear motion like a lifter: rest state (detail a))

[0188] ■ Form of energy: Potential energy of linear elements (press lifter, upper die), possibly additional downwardly directed energy from elements capable of storing energy (eg springs, e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com