Manufacturing method of pneumatic tire

A technology for a pneumatic tire and a manufacturing method, which can be applied to tires, other household appliances, household appliances, etc., can solve the problems such as the decrease of the detachability of the rigid core a, and achieve the effects of preventing peeling and improving the detachability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

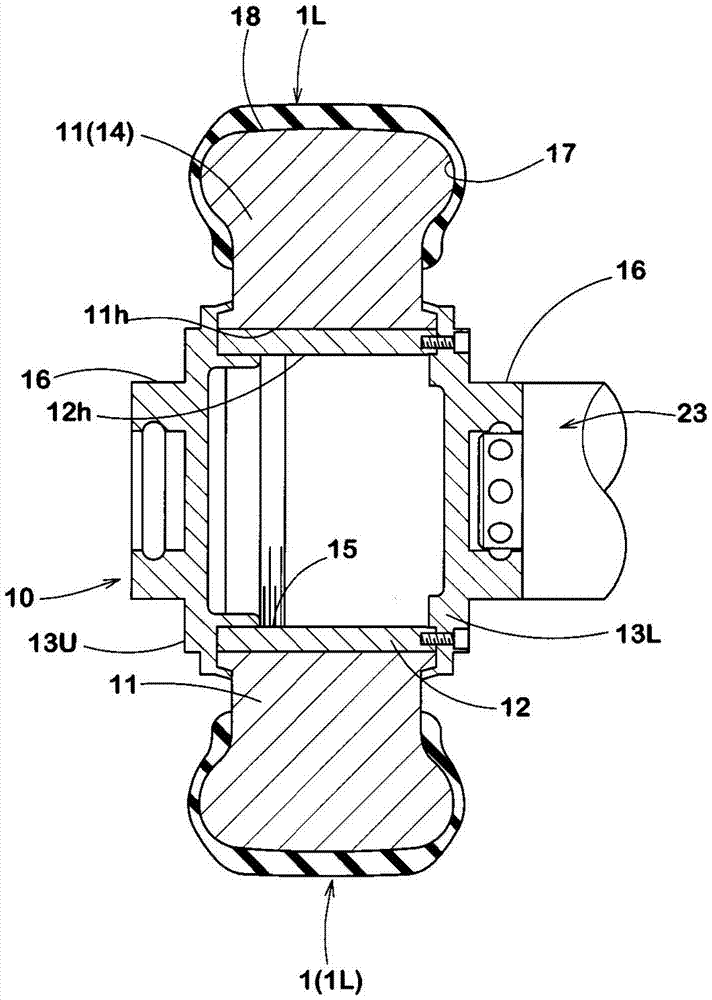

[0070] Based on the manufacturing method of the present invention, tires using the rubber strips shown in Table 1 were produced, and the detachability of their rigid cores and the productivity of the inner liner were evaluated. In addition, for comparison, such as Picture 11 As shown in (a), the same evaluation was performed on a tire in which a rubber strip was pasted in a spiral shape from the inner side to the outer side in the tire radial direction to form an inner liner. Among them, the common specifications are as follows.

[0071] Tire size: 235 / 40R19

[0072] Number of sectors of rigid core: 8

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com