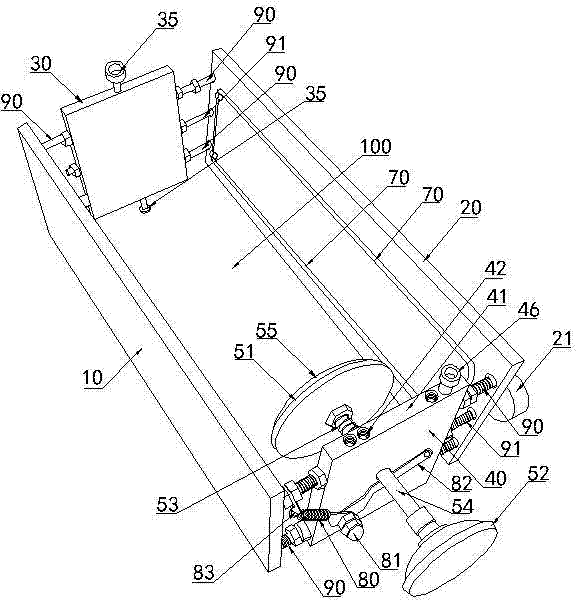

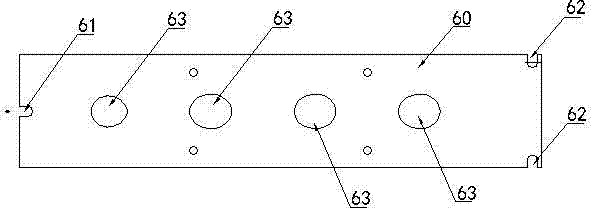

Welding and locating device of capacitor

A welding positioning and capacitor technology, applied in capacitors, capacitor manufacturing, auxiliary devices, etc., can solve the problems of troublesome fixed welding operations and low production efficiency, and achieve stable and reliable welding quality, high production efficiency, and safe, reliable and effective production welding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Although this article uses many terms such as positioning welding pressure plate, side wall clamping plate, first positioning locking column, second positioning locking column, front end baffle, clamping adjustment spring, rear end baffle, etc., The possibility of using other terms is not excluded. These terms are used only for the purpose of describing and explaining the essence of the present invention more conveniently; interpreting them as any kind of additional limitation is against the spirit of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com