Dedicated stretching machine for link link pre-stretching to increase strength

A technology for improving strength and linking links, applied in the direction of metal chains, etc., can solve problems such as high labor intensity, low production efficiency, and difficult clamping, and achieve the effects of high automation, fast operation, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

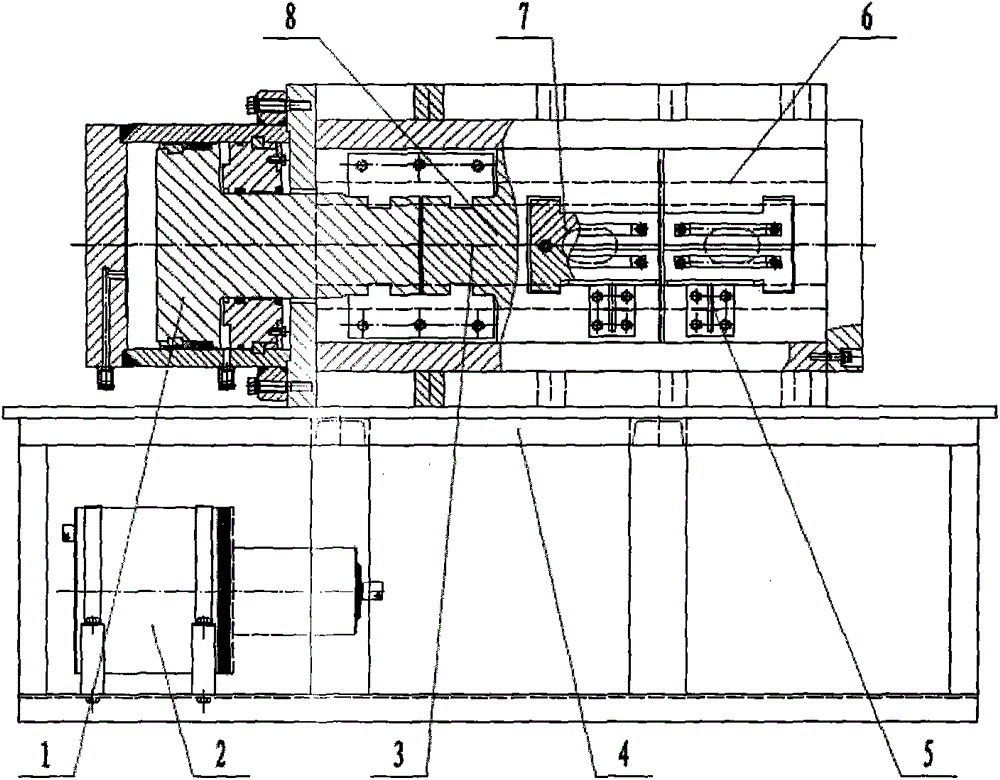

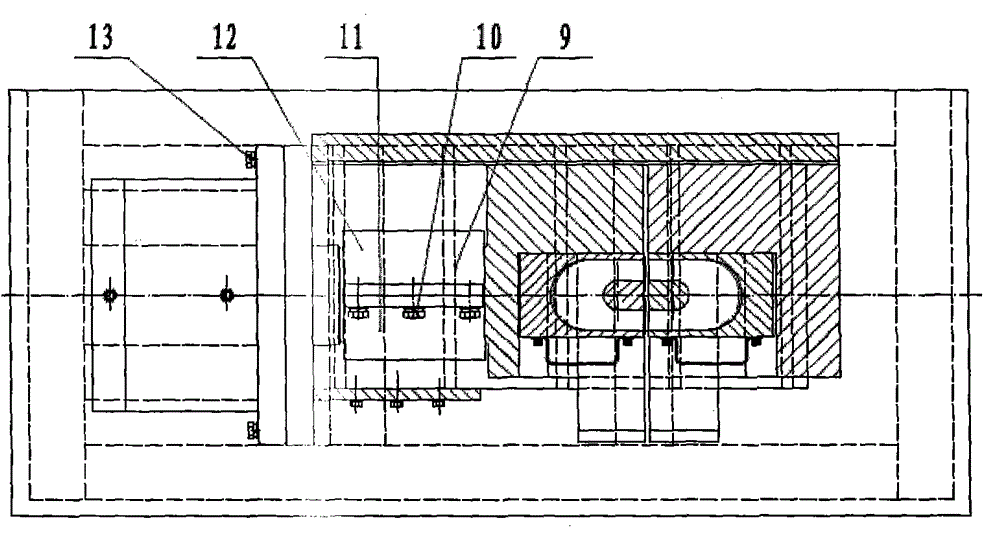

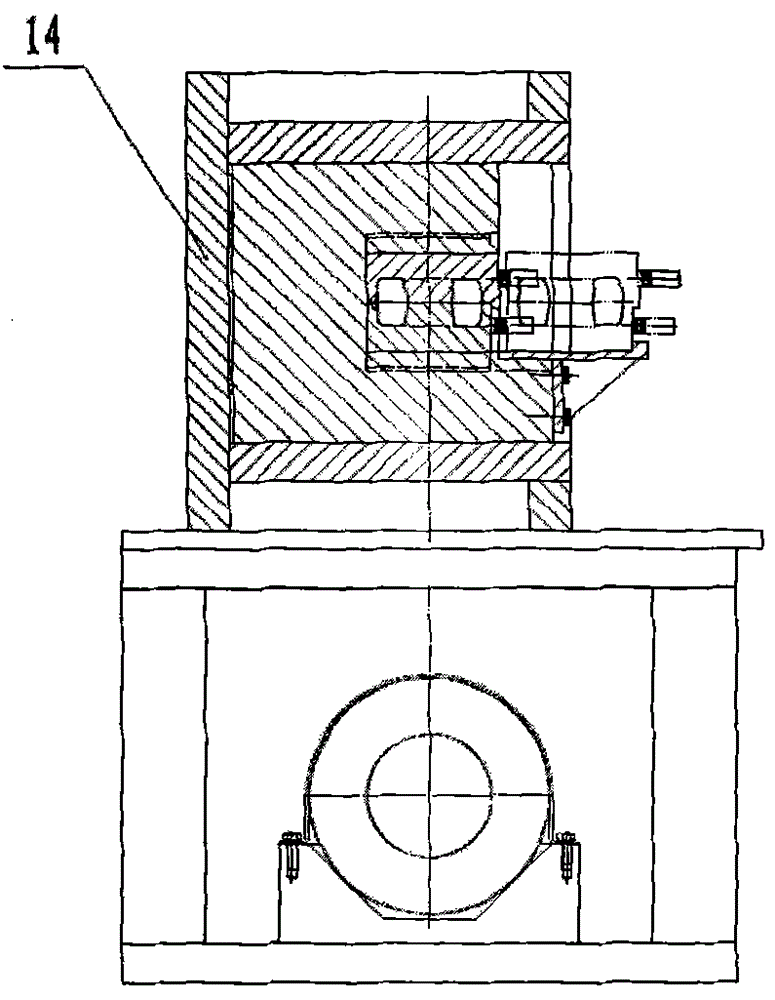

[0015] like figure 1 , 2 As shown in , 3, the special stretching machine tool used for link pre-stretching to improve strength consists of stretching hydraulic cylinder 1, pressurized hydraulic cylinder 2, stretching mechanism 3, base 4, workpiece clamping mechanism 7, connecting mechanism 9. The bed 14 is formed. The stretching mechanism 3 is composed of a left slider 8 and a right slider 6. The right slider 6 is fixed on the right end of the bed 14, and the left slider 8 is connected to the piston rod of the stretching hydraulic cylinder 1 fixed on the left end of the bed 14. 9 are connected together and can move left and right along the groove-shaped slideway of the bed 14 with the extension and recovery of the piston rod. The adjacent ends of the left slider 8 and the right slider 6 are provided with T-shaped slots for mounting workpieces and clamping Mechanism 7 and bracket 5 are fixed on the lower part of the left and right sliders with bolts, and the upper end surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com