Double-end clamping piezoelectric motor for utilizing opposite-direction rubs to reduce friction force and control method

A piezoelectric motor and friction technology, applied in piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, generators/motors, etc., can solve the problem of small thrust of three-friction steppers, Achieve the effect of high integrity and high thrust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1: A basic double-end clamping piezoelectric motor and its control method using opposite rubbing to reduce friction

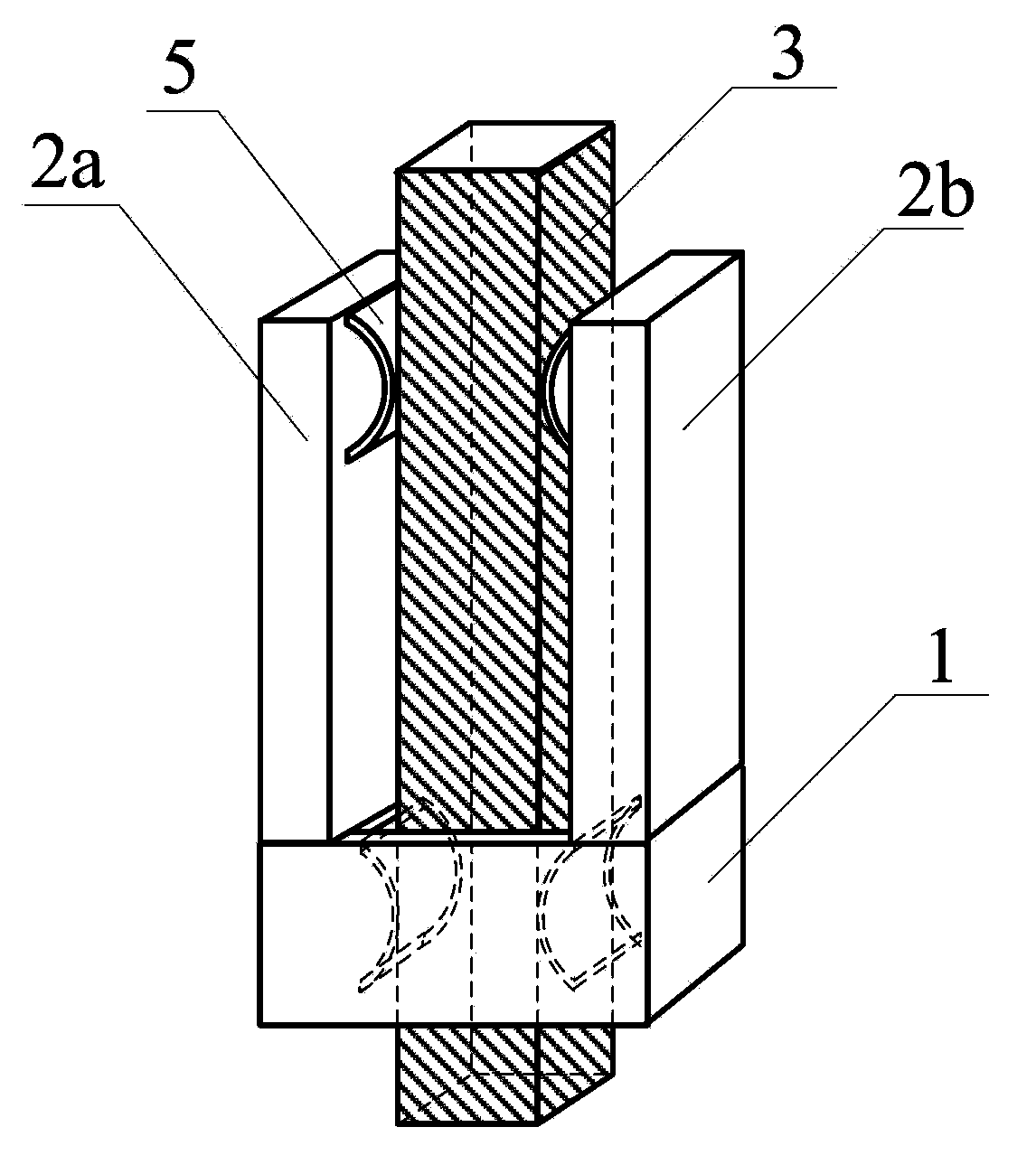

[0049] See attached figure 1 , a basic double-end clamping piezoelectric motor that uses opposite rubbing to reduce friction, including two piezoelectric bodies 2a, 2b, a base 1, and a slide bar 3, and is characterized in that the two piezoelectric bodies 2a, 2b Set parallel to the expansion and contraction direction and fixedly stand on the base 1 side by side, set a slide bar 3 for sliding cooperation with the two piezoelectric bodies 2a, 2b in the expansion and contraction direction, vertical to the expansion and contraction direction of the two piezoelectric bodies 2a, 2b Set the positive pressure that presses the slide bar 3 against the free ends of the two piezoelectric bodies 2a, 2b and the positive pressure that presses the slide bar 3 with the base 1. The friction generated by these three positive pressures on the slide bar 3 satisfie...

Embodiment 2

[0055] Embodiment 2: Elastic double-end clamping piezoelectric motor using opposite rubbing to reduce friction

[0056] In the above embodiment, the slider 3 is elastically pressed against the base 1 through the elasticity of the slider 3 and / or the elasticity of the base 1 and / or the elastic body 5 is added, and the slider 3 is elastically pressed against the base 1 through the elasticity of the slider 3 and / or Or the two piezoelectric bodies 2a, 2b are elastic and / or the elastic body 5 is added to elastically press the free ends of the two piezoelectric bodies 2a, 2b. attached figure 2 An example of adding an elastic body 5 (such as a leaf spring) to generate the required positive pressure is given in . The additional elastic body 5 can also be placed between the slide bar 3 and the two piezoelectric bodies 2a, 2b or one of the two piezoelectric bodies 2a or 2b.

Embodiment 3

[0057] Example 3: A double-ended clamping piezoelectric motor integrated with opposite friction to reduce friction

[0058] In the above embodiments, the two piezoelectric bodies 2a, 2b are integrally arranged, or the two piezoelectric bodies 2a, 2b and the base 1 are integrally arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com