Current hysteresis control digital implementation system for PWM rectifier

A technology of current hysteresis and system realization, which is applied in the direction of converting AC power input to DC power output, electrical components, output power conversion devices, etc., which can solve problems such as noise interference, false triggering, and adjustment, and achieve real-time performance. The effect of good real-time performance and high control precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing, content of the invention will be further described:

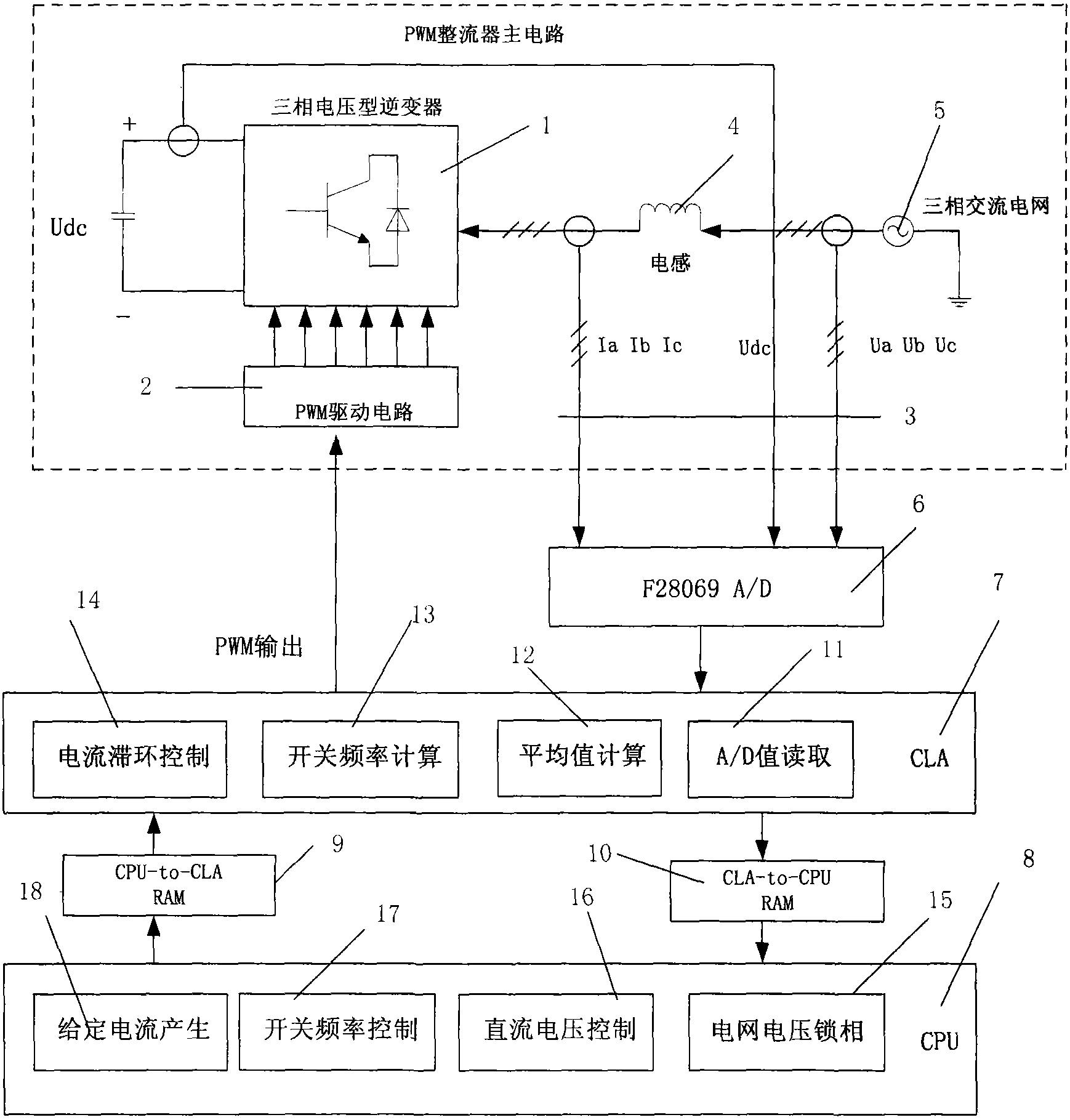

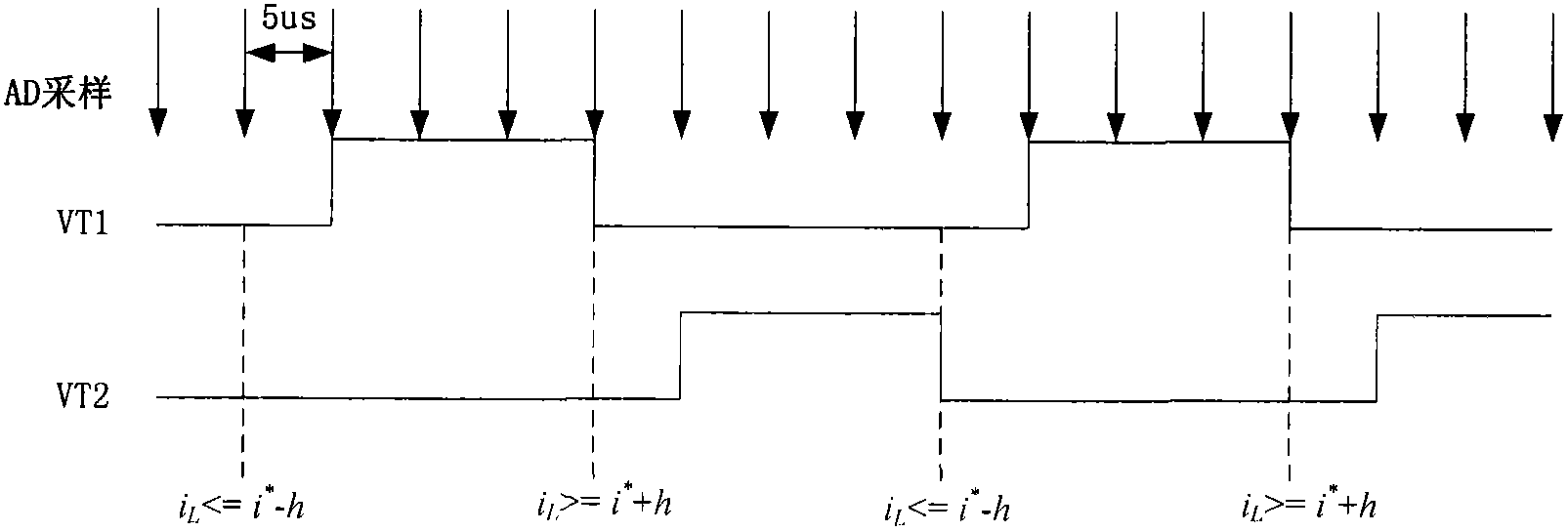

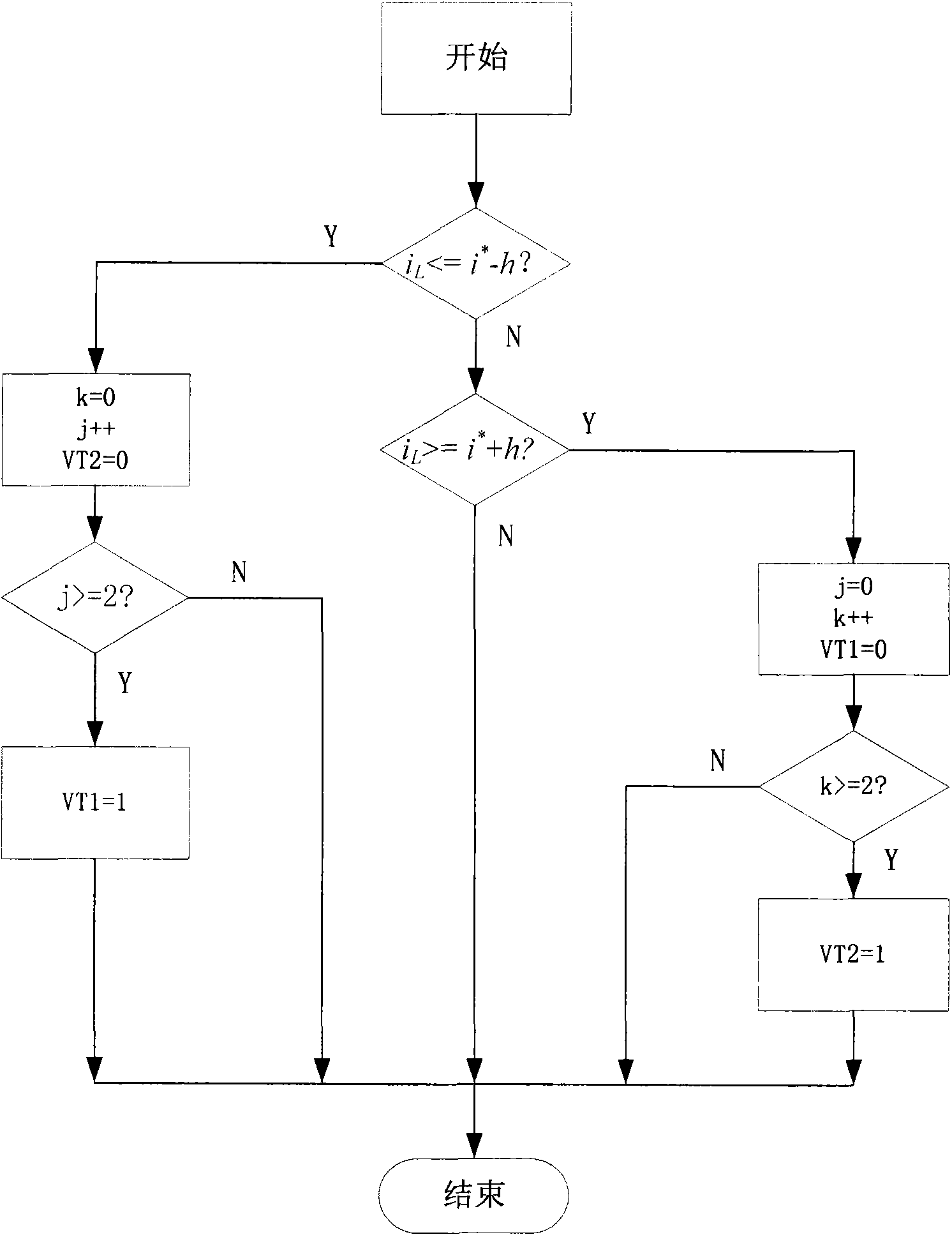

[0019] PWM rectifier current hysteresis control digital implementation system, including sequentially connected PWM drive circuit 2, three-phase voltage type inverter 1, voltage and current signal acquisition part 3, output inductor 4 and three-phase AC grid 5, grid current and DC The voltage is sampled by the A / D circuit 6 of the TI F28069 DSP chip through the signal acquisition part 3 of the voltage and current signal, and the CLA module 6 in the chip directly reads the result of the A / D sampling through the A / D value reading program module 11, And calculate the average value of 100 microseconds by the average calculation program module 12, store in the CLA-to-CPU RAM memory 10, the main CPU module 8 can read by the CLA-to-CPU RAM memory 10 every 100 microseconds These sampling values, combined with these sampling values, calculate the three-phase current setting and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com