Motor rotor and magnet sealing piece thereof

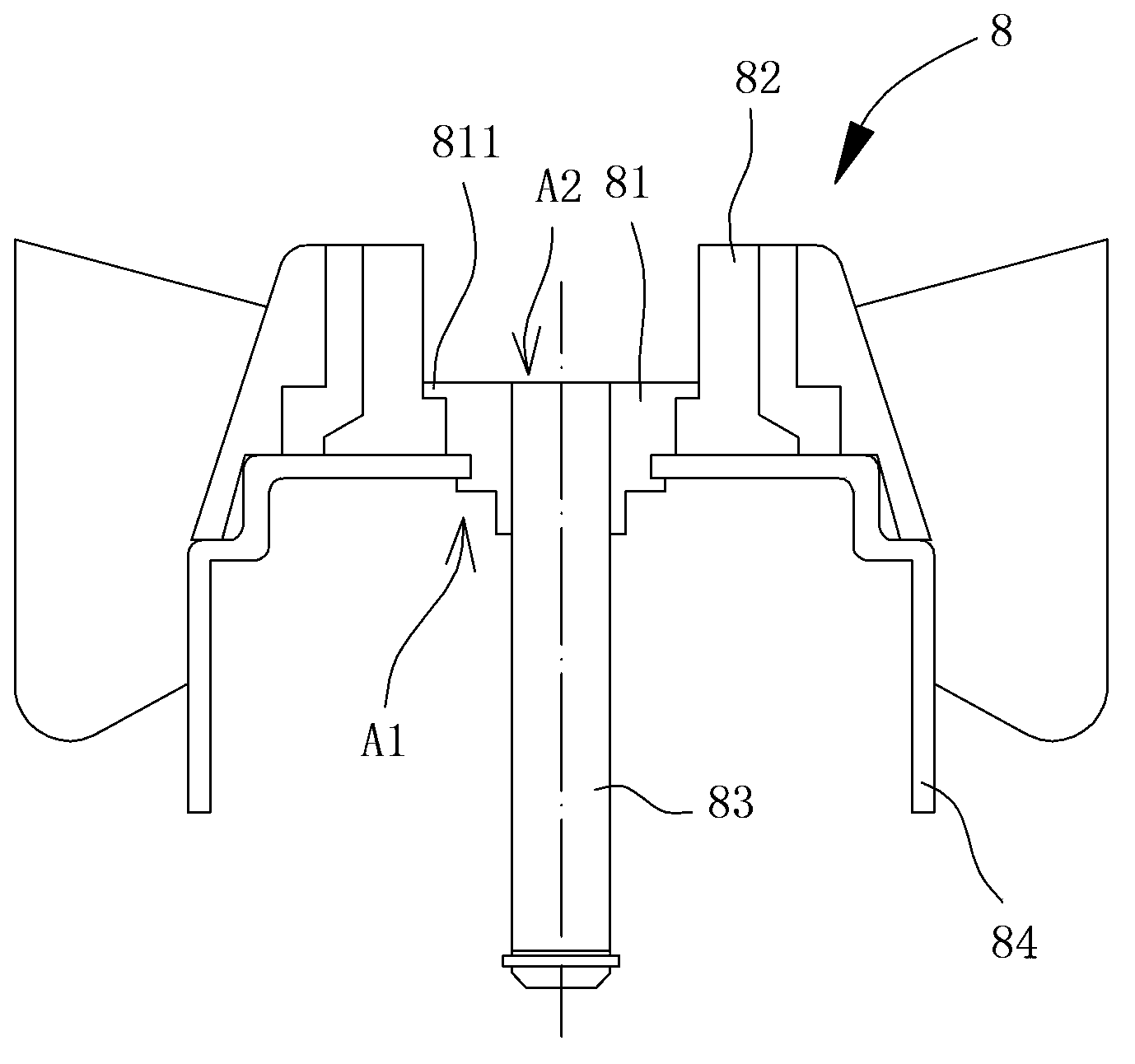

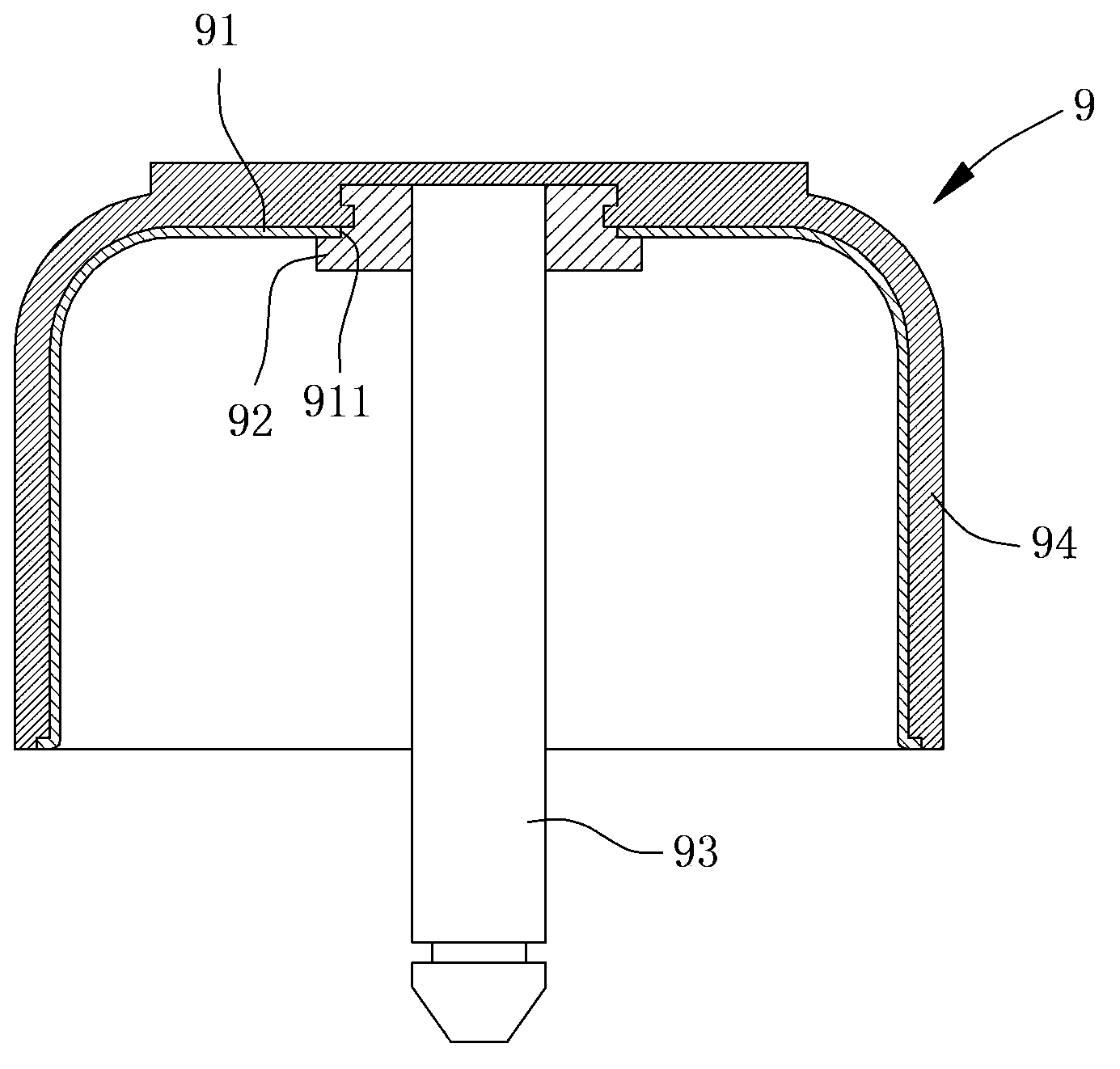

A technology for motor rotors and magnetic parts, applied in the field of motor rotors and their magnetic sealing parts, which can solve the problems of reduced assembly convenience, no structural design of the motor shell 91, and increased manufacturing costs of the motor rotor 9

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to make the above-mentioned and other objects, features and advantages of the present invention more comprehensible, the preferred embodiments of the present invention are specifically cited below, together with the accompanying drawings, as follows:

[0046] Please refer to image 3 As shown, the motor rotor of the present invention includes a magnetic enclosure 1 , a rotating shaft 2 and a hub 3 . Wherein the magnetic sealing member 1 is used to combine with the rotating shaft 2 , and the hub 3 is integrally combined with the rotating shaft 2 and the hub 3 by injection molding.

[0047] The magnetic sealing part 1 can be made into various geometric shapes with the help of thin metal plates, such as stamping, to provide magnetic sealing effects; please refer to Figure 4 As shown, the magnetic sealing member 1 has an opposite first surface 11 and a second surface 12, and is provided with an assembly hole 13 and several positioning holes 14 passing through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com