Pressure releasing device of completely-closed gas insulation high-pressure switch device

A gas-insulated, high-voltage switch technology, applied in switchgear, switchgear settings, electrical components, etc., can solve the problems of low blasting pressure judgment accuracy, increased equipment cost, poor fatigue resistance, etc. The effect of stability and burst pressure error satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

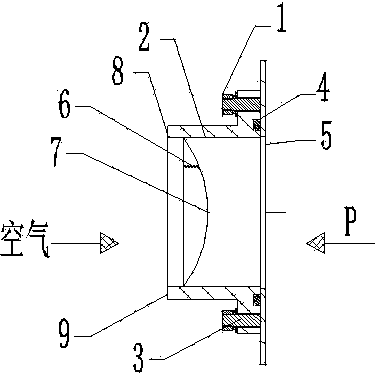

[0020] like Figure 1 to Figure 3 As shown, a pressure release device for a fully enclosed gas-insulated high-voltage switchgear includes a release cylinder 2 with a flange structure, an upper holder 8, a lower holder 9 and a reverse-arched rupture disc 7, which is reverse-arched The bursting disc 7 is fixedly welded and connected to the opening end of the release cylinder 2 by the upper holder 8 and the lower holder 9. The concave surface of the reverse arched rupture disc 7 faces the side of the release cylinder 2 with the flange structure, and releases The device is fixedly connected with the air chamber wall 5 through the flange structure, the stud 3 and the nut 1, and a sealing ring 4 is provided between the flange structure and the air chamber wall 5 .

[0021] When the actual bursting pressure in the cabinet reaches its design bursting pressure due to failure or other reasons, the anti-arched bursting disc will first lose stability and reverse, and then tear apart. SF ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com