Power electronic device, power electronic system and hot swap method of power unit

A technology of power electronic devices and power units, which is applied to substations/switchgear boards/panels/desks, switchgears, electrical components, etc., and can solve problems that cannot be realized, limit the moving range of power unit 1, and power electronic devices cannot realize thermal Easy to maintain and safe to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0079] The aforementioned and other technical contents, features and effects of the present invention will be clearly presented in the following detailed description of preferred embodiments with reference to the accompanying drawings.

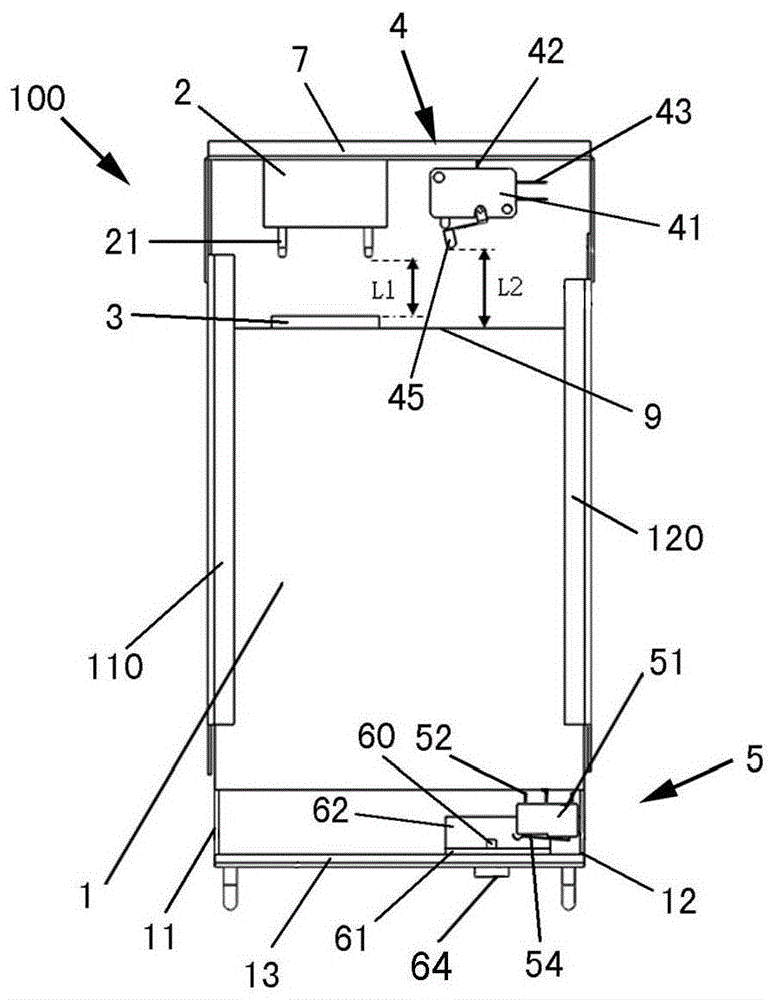

[0080] The technical idea of the present invention is: take the power electronic device as the basic core, cooperate with the power supply, control output terminal and signal output terminal fixed on the installation grid, the power supply and control input terminal and signal input terminal fixed on the power unit, and the power supply unit Slide rails. The power unit slides on the guide rail to connect or disconnect the external current with the power unit, realizing the hot swap function of the power electronic device.

[0081] Power Electronics

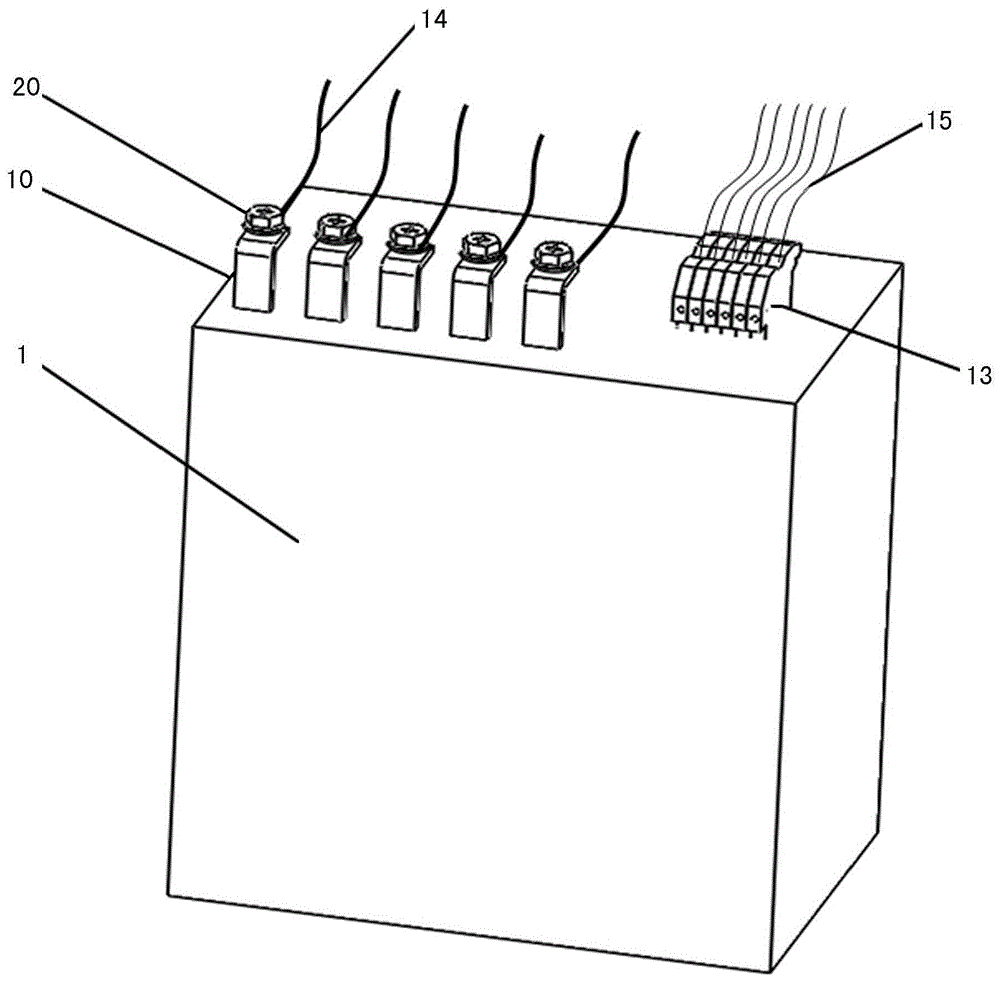

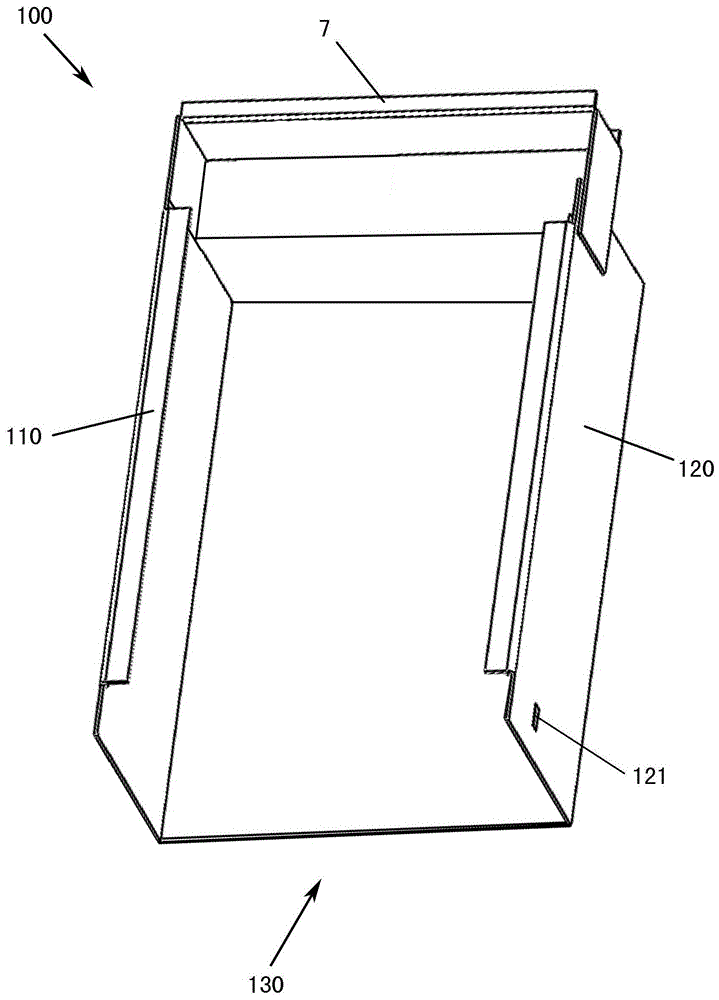

[0082] see Figure 2A to Figure 7B . The power electronic device introduced here includes an installation grid 100 , and a power unit 1 and a micro switch 5 that are hot-swappable to the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com