Method for improving conductivity of pure lithium iron phosphate anode material

A technology of pure lithium iron phosphate and high lithium iron phosphate, applied in the field of electrochemistry, can solve uncertain and controversial problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Synthesis of lithium iron phosphate material

[0032] (1) Raw material preparation

[0033] Weigh 114g (99.9%) of industrial battery grade ferrous oxalate, 73g (99.5%) of ammonium dihydrogen phosphate, and 24g (99.9%) of industrial battery grade lithium carbonate;

[0034] (2) mixed

[0035] Mix the above-mentioned materials weighed in a circular container, then add acetone, the volume ratio to the material is 2:1, fully stir until there are no bubbles, and then continue to stir for 2 hours;

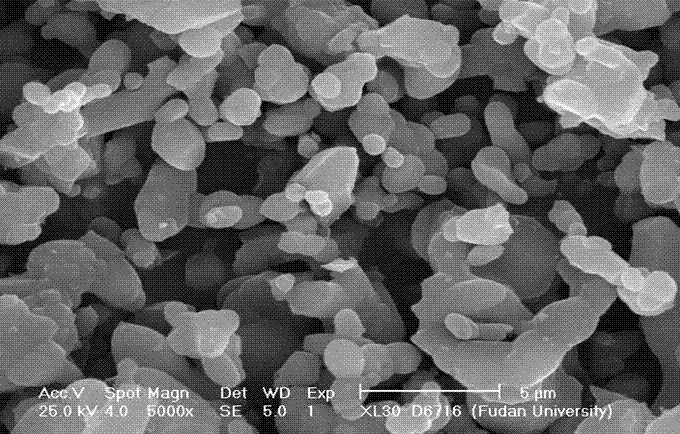

[0036] (3) Ball milling

[0037] Mill the above-mentioned materials after drying in an ordinary centrifugal ball mill at 500 rpm for 10 hours, and the particle diameter is less than 5 microns;

[0038] (4) dry

[0039] The ball-milled sample was baked at 108oC for 10 hours in a common oven until dry;

[0040] (5) Calcination

[0041] The ball-milled material is placed in a high-temperature tube furnace, and calcined at 350oC for three hours and at 600oC for six hours in an...

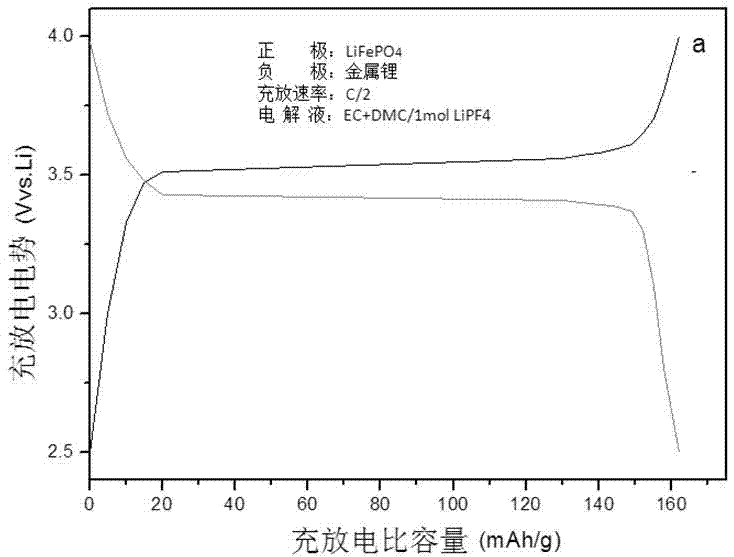

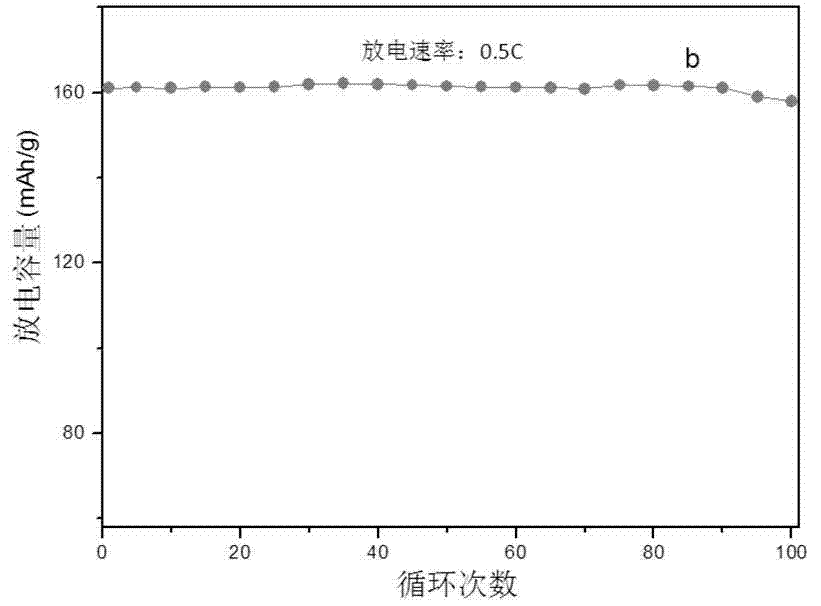

Embodiment 2

[0045] Button battery manufacturing process,

[0046] (1) Slurry preparation

[0047]Weigh lithium ferrous phosphate material: PVDF=0.975::0.025, add lithium ferrous phosphate in an agate mortar and grind for 10 minutes, then bake in an oven at 78 degrees Celsius for 1 hour, add PVDF, and add a certain amount of NMP After that, stir for 1 hour;

[0048] (2) Coating

[0049] Put the 20 micron thick aluminum foil for lithium-ion batteries on the smooth surface of the coating machine, then flatten it, pour the slurry into the coating machine for coating, ensure that the slurry is evenly distributed on the aluminum foil, and the thickness is 200 microns ;

[0050] (3) drying

[0051] Put the aluminum foil coated with lithium iron phosphate cathode material in an ordinary drying oven and bake it for about 10 hours to dry completely; (4) Rolling

[0052] The dried lithium iron phosphate aluminum foil is compacted with a gap of 100 microns on the roller machine, and the total th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com