Standard lamp

A standard lamp and filament technology, applied in the direction of the shell/shell of the luminous body, luminous body, etc., can solve the problems of complex structure, increased production cost, and difficulty in obtaining stable light intensity values, and achieve strong uniformity, easy adjustment, The effect of enhancing the stability of light emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

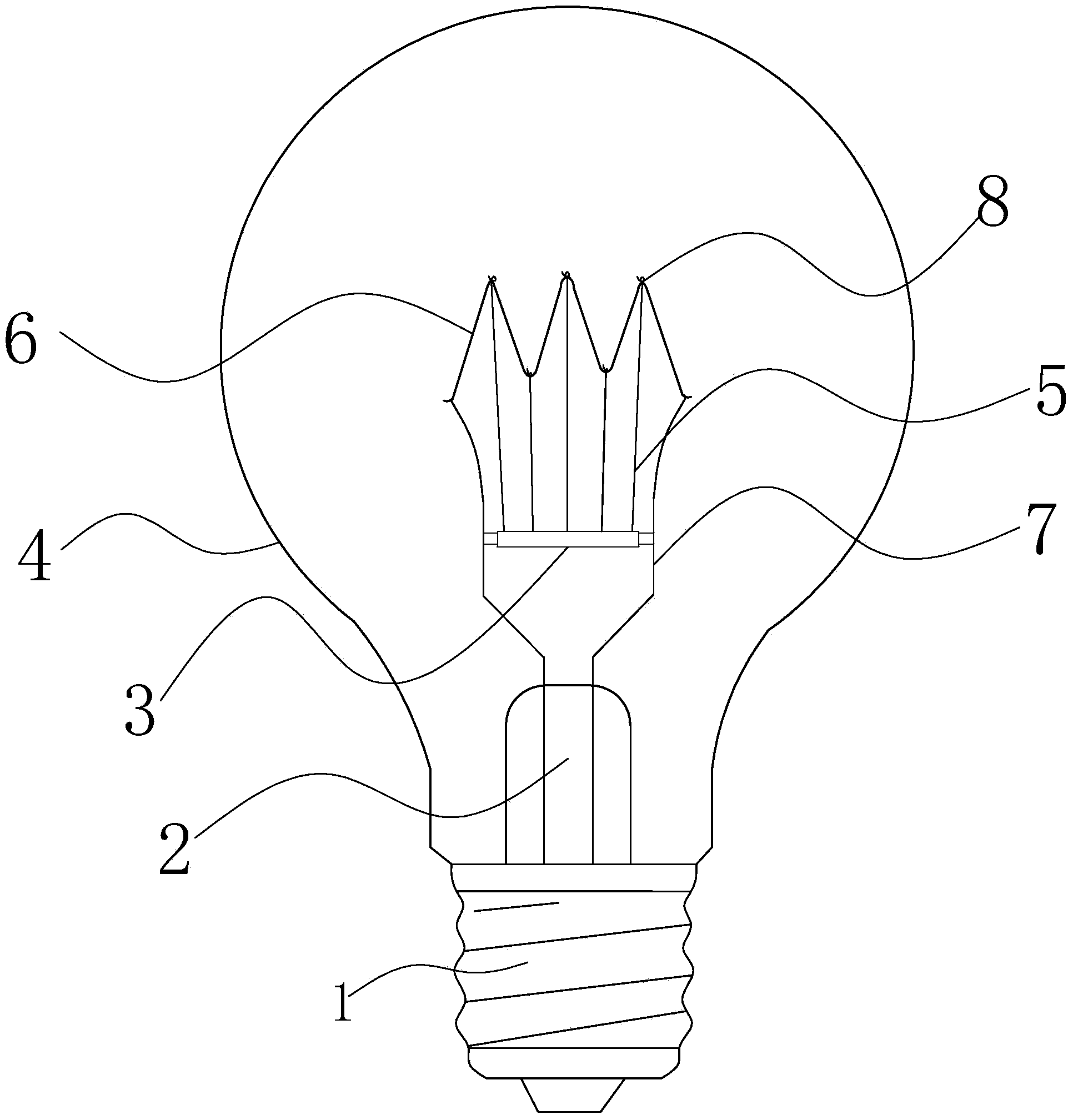

[0010] Such as figure 1 A standard lamp shown includes a lamp cap 1, a glass bulb 4, a stem 2 and a filament 6 are arranged inside the bulb 4, two guide wires 7 are drawn out of the stem 2, and the two ends of the filament 6 are respectively Connected with two guide wires 7, the glass bulb 4 is spherical, and a fixed seat 3 is connected between the two guide wires 7, and several high and low molybdenum wire hooks 5 are arranged on the fixed seat 3, and the filament 6 Pass through the hook portion 8 on the top of the molybdenum wire hook 5 sequentially from left to right, the filament 6 is distributed in an M shape, and the filament 6 is all on the same plane, and the distance from the plane to the front and rear glass bulbs 4 is equal, so The distance from the left end of the filament 6 to the left glass bulb 4 is equal to the distance from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com