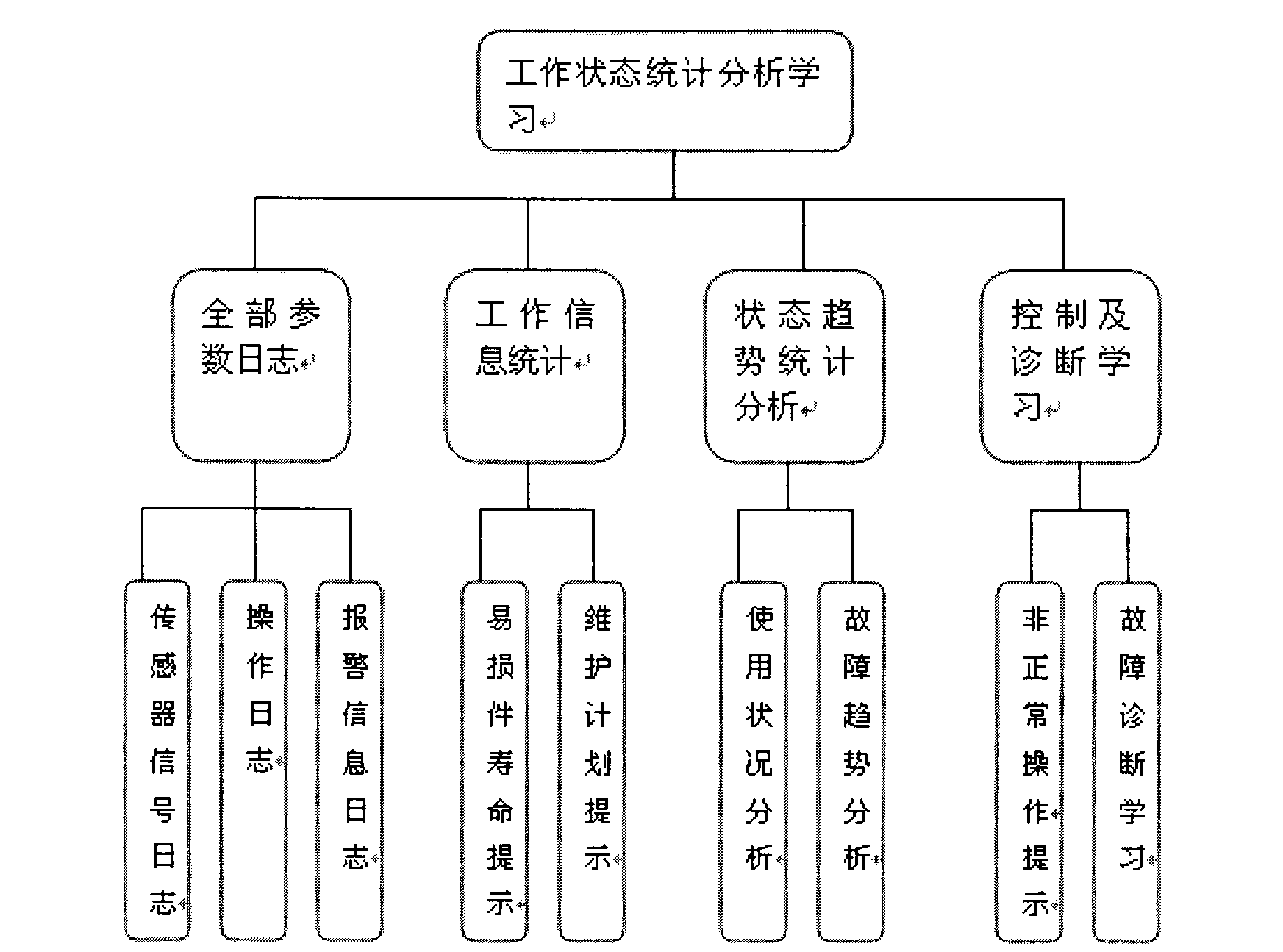

System for statistical analysis and learning on working state of hydraulic hoist

A technology of hydraulic hoist and working status, which is applied in calculation, comprehensive factory control, comprehensive factory control, etc., and can solve problems such as high requirements for users, high maintenance costs, and prone to errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The present invention is specifically as follows to the computing prompt of sealing ring life:

[0026] The system sets different life stroke thresholds according to the material type and specific model of each sealing ring. The piston rod stroke sensor senses the movement distance of the piston rod and transmits it to the PLC. The system accumulates statistics on the piston rod stroke information transmitted by the PLC. When the overall stroke When a threshold value set in advance is reached, the system will give a prompt that the corresponding sealing ring should be replaced in time when its service life is reached.

Embodiment 2

[0028] The system’s learning of manual operations and early warning of abnormal operations are as follows:

[0029] When the operator restarts the gate operation after power failure, the normal operation action sequence is "power on the hydraulic station, open the fuel tank valve, open the oil circuit valve, open the gate". The system records the operation action sequence. When the same operation action sequence repeats history for three times , the system defines the operation action sequence as the usual sequence. When an operator performs the operation action sequence as "power on the hydraulic station, open the ball valve of the fuel tank, and open the gate", the system suspends the action and sends out a prompt "different from the usual operation sequence. The road valve is not open" to avoid misoperation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com