Intelligent fan blade manufacturing method

A technology of intelligent manufacturing and fan blades, applied in the direction of digital control, program control, computer control, etc., can solve the problems of difficult to grasp process parameters, heavy repetitive labor, and easy torsion deformation, etc., to achieve intelligent preparation and realization Automatic execution, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

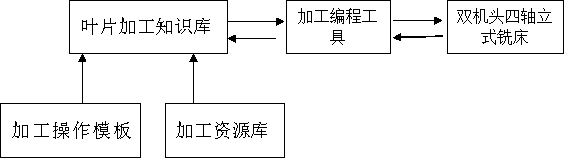

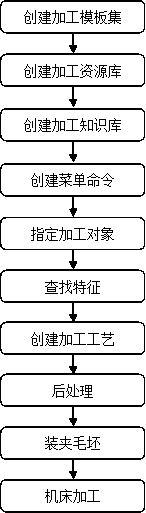

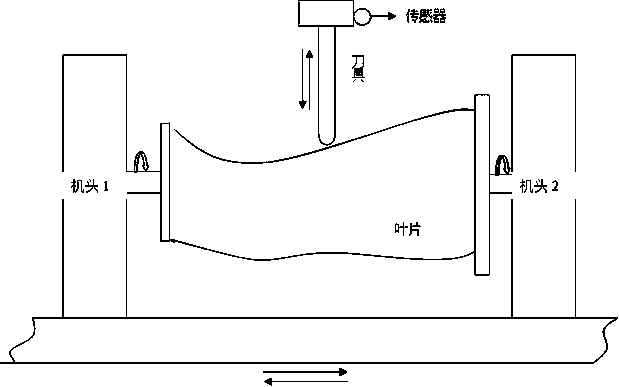

[0046] see Figure 1-Figure 3 , the intelligent manufacturing method of the fan blade is characterized in that by defining the processing knowledge base and the processing resource base in the computer-aided processing tool, the feature recognition rules and feature processing rules are compiled for the blade model created by applying MBD technology, and the process is completed through the program Identify the characteristics of the blade and intelligently create the blade processing technology, and then send the program to the vertical four-axis milling machine equipped with dual heads and sensors for processing. In this way, the quality of the processed blade is guaranteed on the one hand, and the On the one hand, the automatic feedback of processing information and the automatic execution of related commands are realized, so as to realize the intelligentization of blade processing program and the intelligentization of blade processing and manufacturing. The operation steps...

Embodiment 2

[0047] Embodiment 2: This embodiment is basically the same as Embodiment 1, and the special features are as follows:

[0048] (1) Define the types of processing operations that may be used in the blade processing process in the form of files in a specific location as a processing operation template set. When realizing the intelligent manufacturing method of the blade, the extension definition is carried out in the existing computer-aided processing tools. In general computer-aided processing tools, if a part needs to be programmed with NC toolpath, a series of steps such as creating machine tool coordinate system, creating geometry, creating tool, and creating processing operation are required, and the steps are relatively cumbersome.

[0049] (2) Define the tool types and machine tool types that may be used in blade processing in the form of files in a specific location as a processing resource library. In the process of creating tool paths for various parts, it is generally...

Embodiment 3

[0058] Embodiment three: This implementation is described as follows according to the figure:

[0059] first in figure 1 The system architecture of this method is described in , this method uses the existing CAM tool as the platform, after opening the blade model to be processed in the CAM tool, by specifying the blade as the processing object, firstly call the processing knowledge base through the custom menu to process the blade Feature Lookup, checks for features contained in the library. By comparing the existing features in the processing knowledge base with the target object, the identified features are fed back to the CAM tool, and the identified features are listed in the form of a list in the CAM tool.

[0060]After the identification of the blade features is completed, select the identified blade features, and create a machining operation for the identified blade features by selecting a custom menu command. At this time, it is a call to the machining rules in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com