Dustproof mining camera

A camera and dust-proof technology, which is applied in the field of cameras, can solve the problems of dust-proof failure, easy residual watermark on the lens, and contamination of the camera lens, so as to achieve the effect of maintaining cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

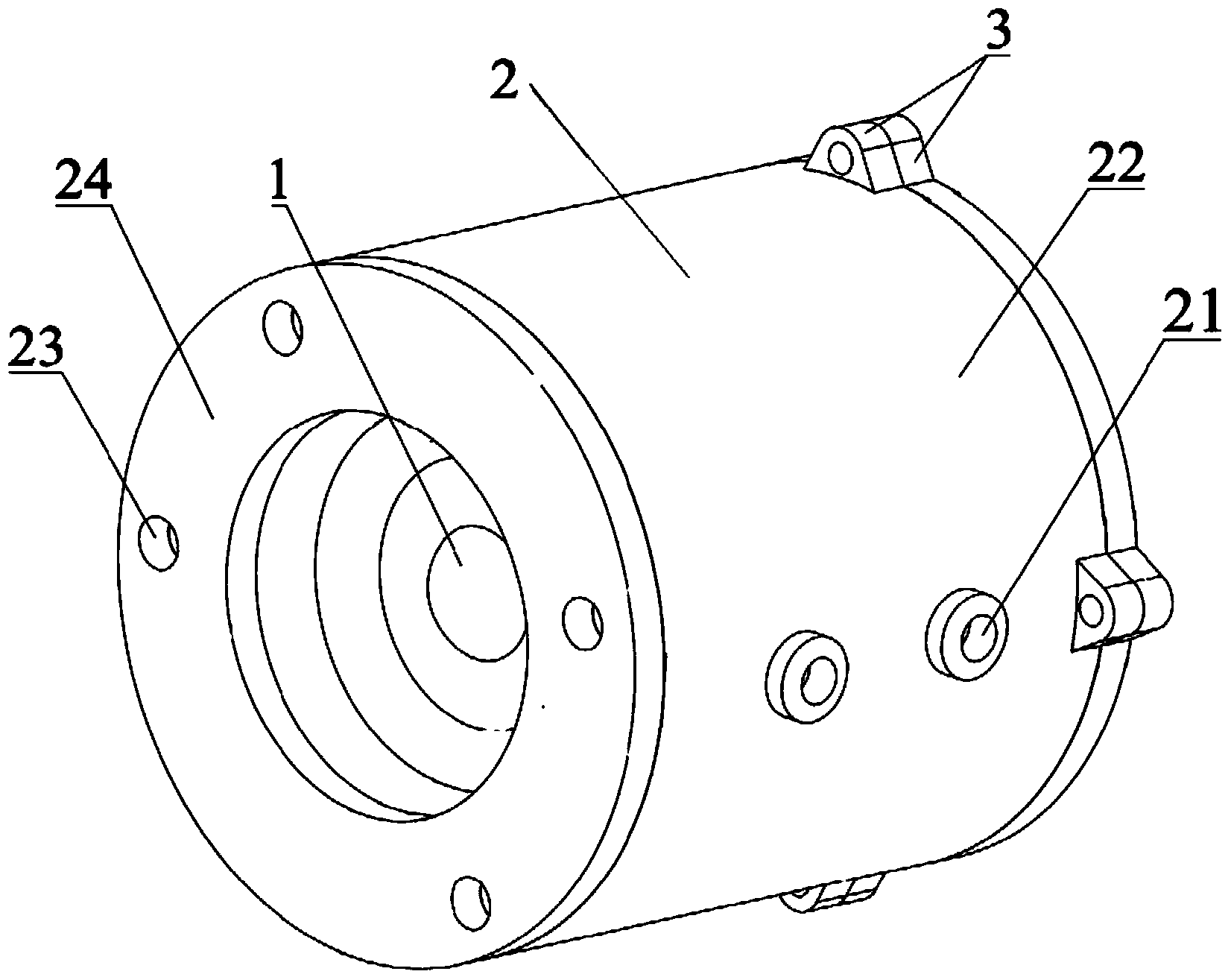

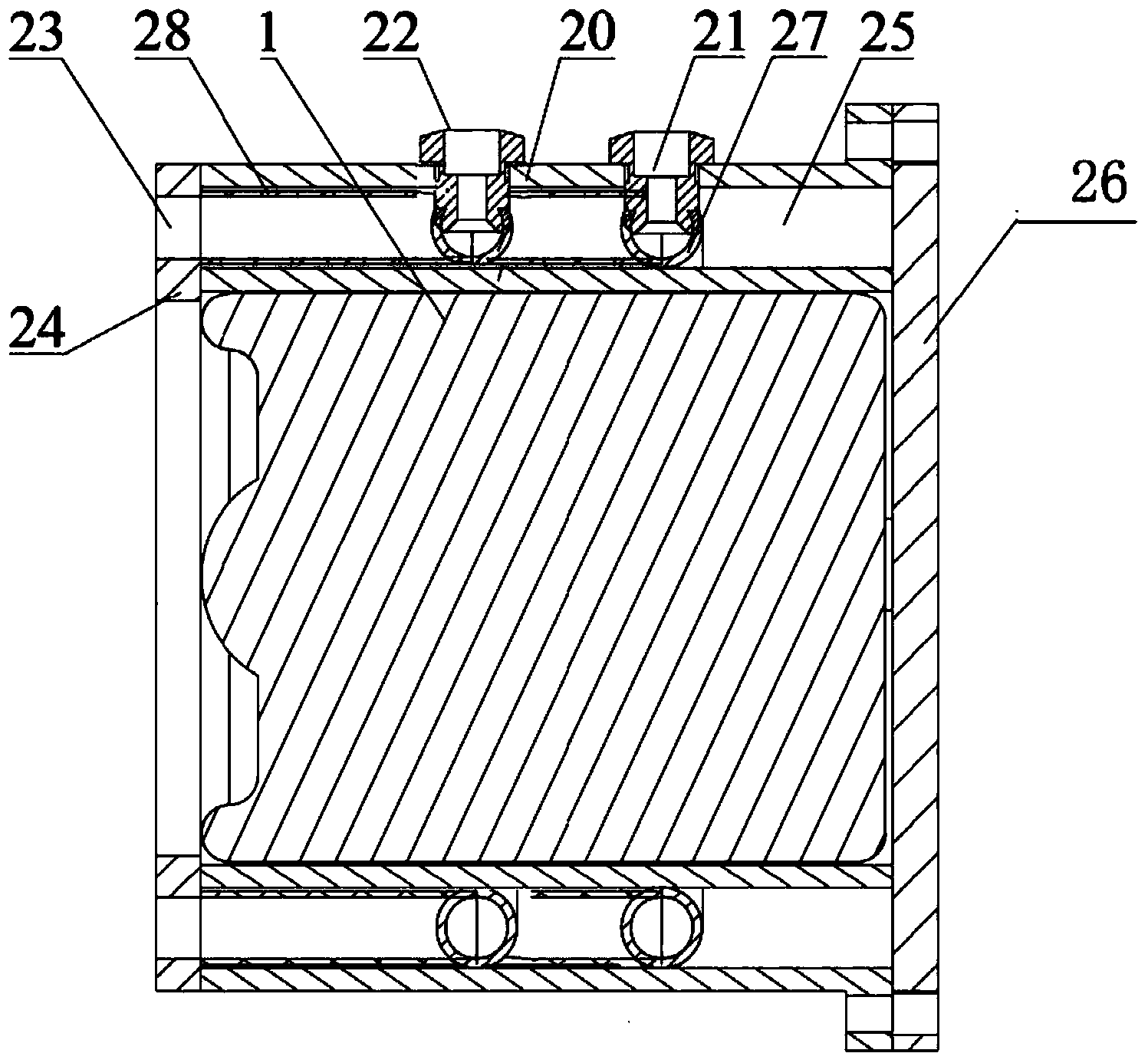

[0016] Such as figure 1 As shown in and 5, a mining dust-proof camera head of the present invention includes an inner layer sleeve 20 for being sleeved on the outside of the camera head, an outer layer sleeve 22 is sleeved outside the inner layer sleeve 20, and the inner sleeve A gas chamber 25 is formed between the layer sleeve 20 and the outer sleeve 22; the front end cover 24 is arranged at the front end of the gas chamber 25, and the rear end cover 26 is arranged at the end of the gas chamber 25; The front end cover 24 is provided with an air outlet 23, and the wall of the outer sleeve 22 is provided with an air inlet 21; the gas cavity 25 is provided with an arc pipe 27 and a connecting pipe 28; The arc tube 27 is provided with a hole communicating with the air inlet 21; the front end of the communicating tube 28 is connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com