Automatic ship draught detection system based on multi-beam side-scan sonar technology

A technology of side-scan sonar and draft, which is applied in radio wave measurement system, sound wave re-radiation, measurement device, etc. It can solve the problem that cannot meet the requirements of "fast and automatic" detection, and has not yet been marketed and finished products. , affect the normal development of shipping scheduling, etc., to achieve the effect of simple and efficient measurement process, reduce the difficulty of construction and maintenance, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

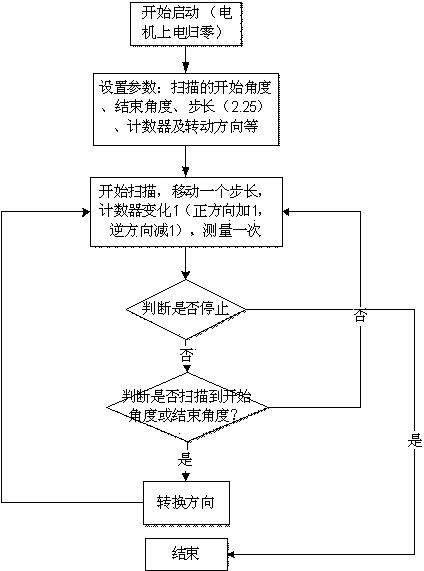

[0039] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0040] like figure 1 As shown, a ship draft automatic detection system based on multi-beam side-scan sonar technology in an embodiment of the present invention includes an underwater sonar scanning subsystem, a sonar signal processing subsystem and a main control subsystem;

[0041] The underwater sonar scanning subsystem includes a sonar transducer with a 360° rotating shaft and a rotating motor that drives the sonar transducer to rotate;

[0042] The sonar signal processing subsystem includes a watertight electronic cabin and a digital signal processing module located in the watertight electronic cabin; the sonar signal processing subsystem transmits data and commands through a watertight cable and the main control subsystem;

[0043] The rotating motor of the underwater sonar scanning subsystem is fixed in the watertight electronic ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com