Retractable coil magnetic particle flaw detector with compatible wheel diameter

A magnetic particle flaw detection and coil technology, which is applied in the direction of material magnetic variables, etc., can solve the problems of low flaw detection sensitivity, unstable magnetization current, heavy quality, etc., and achieve the effects of high flaw detection sensitivity, high magnetization efficiency, and strong impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

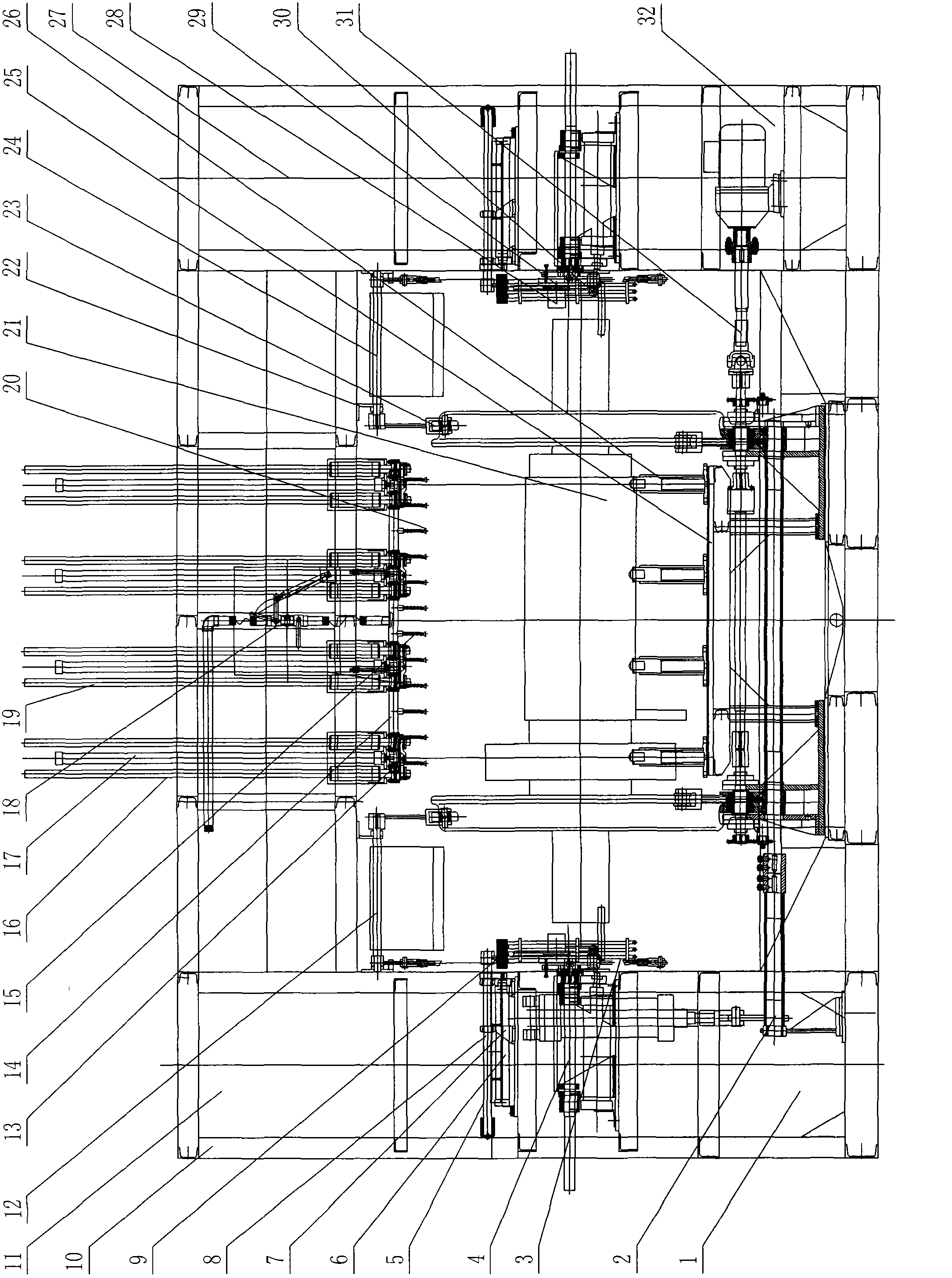

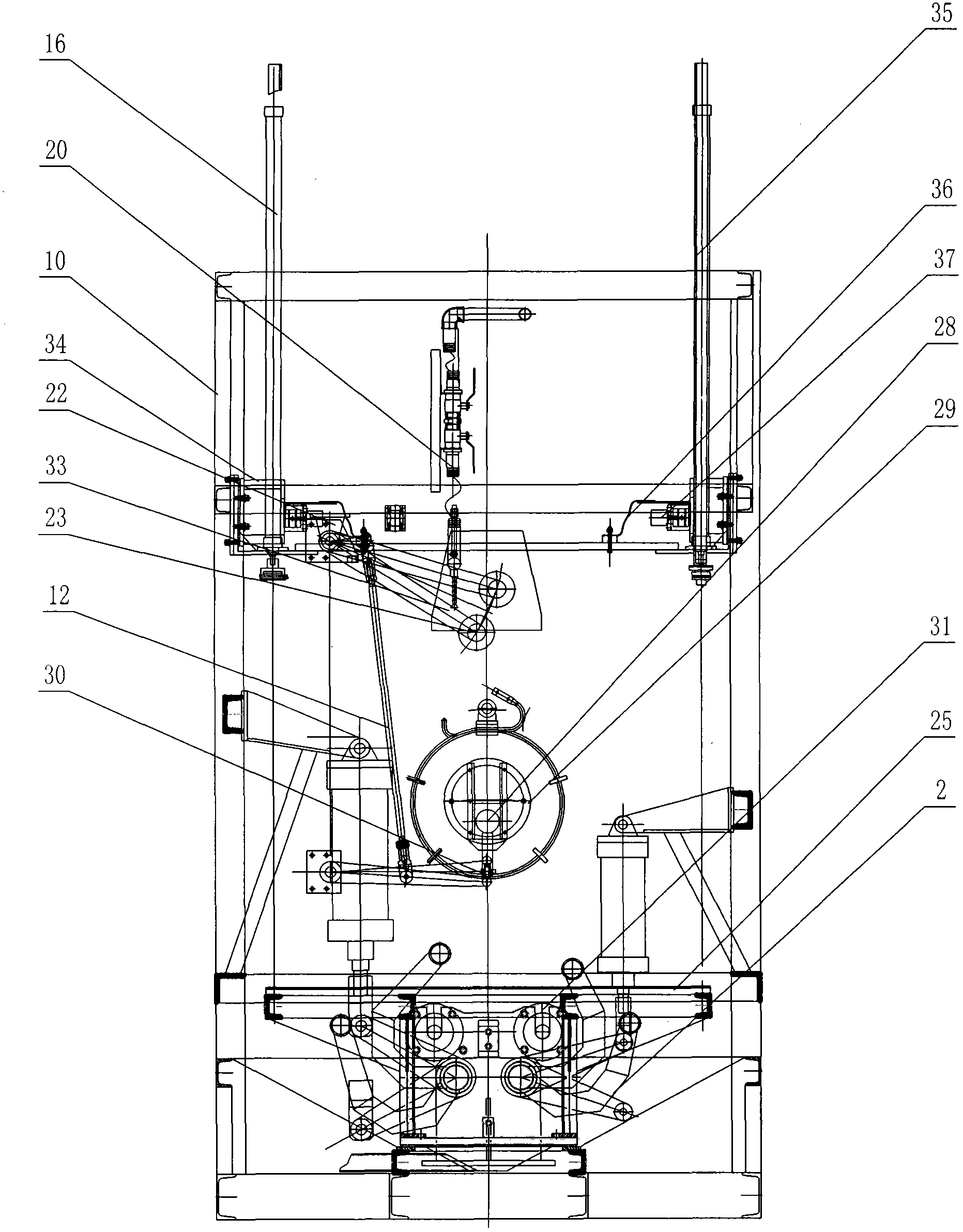

[0014] exist figure 1 , 2 , 3, and 4, the magnetic particle flaw detection machine includes a circumferential magnetization current source 1, a feeding and discharging device 2, an electrode clamping device 4, a coil moving device 5, a frame 10, a program control system warehouse 11, a centering device 12, an opening and closing device Coil, main spraying device 20, industrial computer system warehouse 27, supporting wheel rotating device 31, frame 10 is a rectangular gantry frame, and the left and right sides of frame 10 are made into unit body from top to bottom, and the left side The top of the unit body is equipped with a program-controlled system warehouse 11, and the bottom is equipped with a coil moving device 5, an electrode clamping device 4, a centering device 12, a circumferential magnetization current source 1, and the top of the right side unit cabinet is equipped with The industrial computer system warehouse 27 is equipped with a coil moving device 5, an electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com