A sapphire fiber optic temperature sensor using a separate probe

A technology of optical fiber temperature and sapphire, which is applied to thermometers, thermometers, instruments, etc. that change physically/chemically, and can solve problems that affect temperature measurement accuracy, long-term stability, and surface degradation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

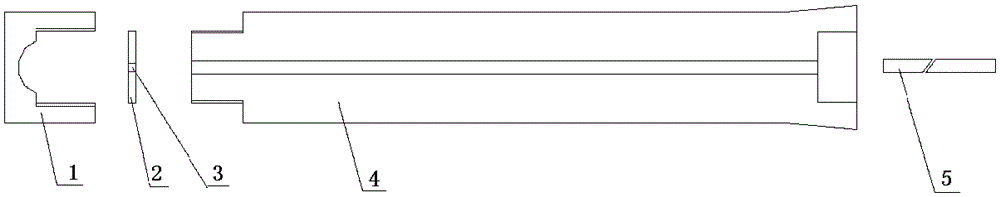

[0024] Follow the steps below to manufacture a box-type temperature-sensitive black body cavity

[0025] Step 1: Using modified zirconium boride ceramic materials to prepare cylindrical blanks with two diameters;

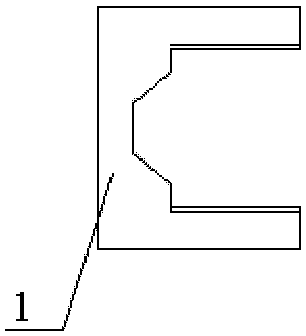

[0026] Step 2: Process a box-type temperature-sensitive blackbody cavity 1 on a larger cylindrical blank by using EDM technology. The bottom of the temperature-sensitive blackbody cavity is hemispherical and the upper end is cylindrical; process internal threads at the mouth of the blackbody cavity;

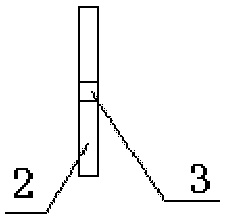

[0027] Step 3: Cutting a small cylindrical blank to produce a circular light-blocking sheet 2, and machining a radiation adjustment hole 3 with a diameter of 1 mm in the center of the light-blocking sheet by EDM;

[0028] Step 4: Install the light blocking sheet 2 into the temperature-sensitive black body cavity 1.

[0029] Follow the steps below to fabricate a sapphire fiber optic temperature sensor probe

[0030] Step 1: Prepare the ceramic protective sleeve 4, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com