Method for measuring depth of parallelism of two planes

A measuring method, a technique for parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments:

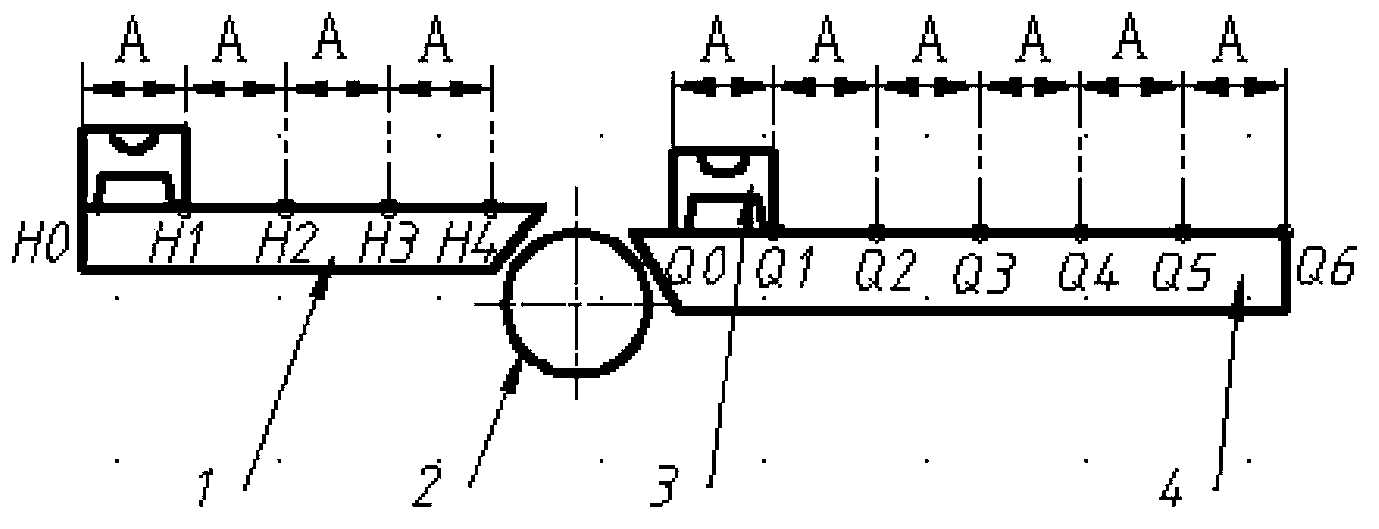

[0010] figure 1 As shown, the longitudinal parallelism of the front table 4 relative to the rear table 1 is to be measured. We regard the back table 1 as the reference plane, and the front table 4 as the measured plane. Divide the front and rear worktables into several measuring points H0, H1, H2, H3, H4...HN; Q0, Q1, Q2, Q3, Q4, Q5, Q6...QN with equal spacing A respectively. The distance A is the span of the level 3 or the bridge board placed under the level (in fact, when the level is measured, it should be connected end to end, that is, the measurement starting point of the latter span should coincide with the end point of the previous span measurement, and the distance A should be smaller than that of the previous span. The span of the level or bridge is one bearing length less). In this way, the indicated values of each meas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com