Movable type high temperature smelting furnace and melt crystallization control process after high temperature smelting

A technology of high-temperature smelting and melt crystallization, which is applied in the direction of crystallization separation, furnace, furnace type, etc., can solve problems such as short melt crystallization time, affecting product quality, coarse and uneven grains of the final product, and achieve fine and uniform grains , The effect of prolonging the holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

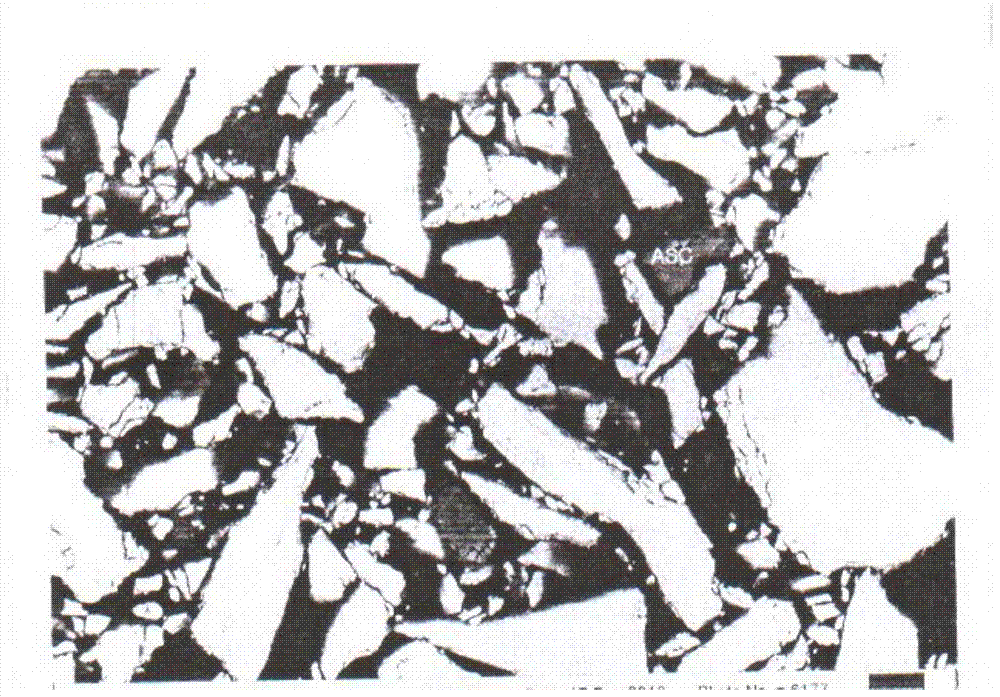

[0033] Do not dump the zirconia melt, but keep it in the furnace for heat preservation, and cool down slowly with the furnace. Cooling process such as Figure 6 , the melt undergoes slow crystallization for about 19 hours, and the temperature drops below 1000°C to complete the crystallization. Lift the furnace body away and take out the crystallized product. Such as Figure 7 As shown, the crystallized product is scanned to detect a particle size range of about 1 to 3 microns, and a high-quality product with fine and uniform crystal grains is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com