Solar steam boiler system

A technology of solar steam and solar energy, which is applied in the direction of control system, steam generation, steam generation method, etc., can solve the problems of large consumption of drinking water, narrow utilization area, pollution and large energy consumption, so as to reduce energy loss and maintain Thermal efficiency, the effect of reducing system fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

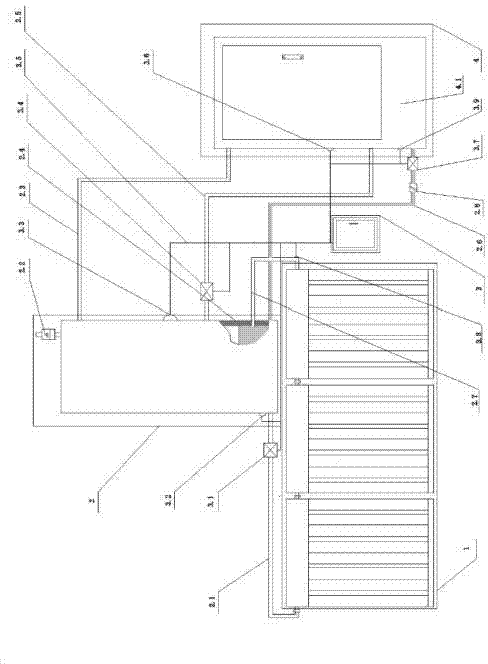

[0016] The solar steam boiler system consists of four parts: solar heat collector area (1), pressurized steam insulation barrel (2), automatic controller (3), and steam heat exchange cooling area (4). It is characterized in that: the solar heat collector area (1) is connected to the bottom of the pressurized steam insulation barrel (2) through the solar output pipeline (2.7) and the solar return water pipeline (2.1), and the solar energy output pipeline (2.7) is connected to the solar collector A solar water temperature probe (3.8) is installed at the joint of the hot plate area (1), and a forced circulation pump (3.1) is installed on the solar return water pipeline (2.1). The pressure-bearing steam insulation barrel (2) is equipped with a temperature and pressure sensing probe (3.3) in the middle, a pressure reducing valve (2.2) and a steam output pipeline (2.3) in the upper part, and the other end of the steam output pipeline (2.3) is connected to the steam heat exchange radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com