Comprehensive utilization method and comprehensive utilization system for biochemical sludge

A biochemical sludge and dry sludge technology, applied in the field of environmental protection and resource recycling, can solve problems such as no good solution, secondary pollution of flue gas, death of herbivores, etc., and achieves low investment and energy utilization rate. The effect of high and low operation and maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

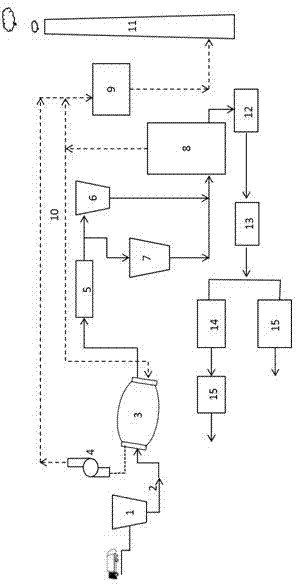

[0029] Embodiment 1: The comprehensive utilization method of biochemical sludge adopts the following process.

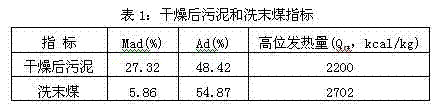

[0030] The biochemical sludge is transported by automobile to the wet sludge storage tank 1, and enters the rotary dryer 3 through the conveying belt 2. The rotation speed and rotary drying time of the rotary dryer are controlled by DCS. Part of the hot flue gas discharged from the circulating fluidized bed is blown by the fan 4 Suction spin dryer 3. After drying, the dry sludge is sent to the crusher 5 by the conveyor belt, and the crushed dry sludge directly enters the dry sludge silo 6 through the conveyor belt, or is mixed with other boiler fuels and then transported to the mixing silo 7 by the belt. , the fuel from the silos 6 and 7 is transported into the circulating fluidized bed boiler 8 to burn and release heat to generate steam, and part of the flue gas generated after combustion enters the rotary dryer 3 through the flue gas pipeline 10 to dry the wet slud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com