Backlight module

A backlight module and backlight technology, applied in optics, light guides, light sources, etc., can solve problems such as deformation of the light shielding cover, deformation and cracking of the light guide plate 13, and achieve the effect of improving quality and enhancing heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

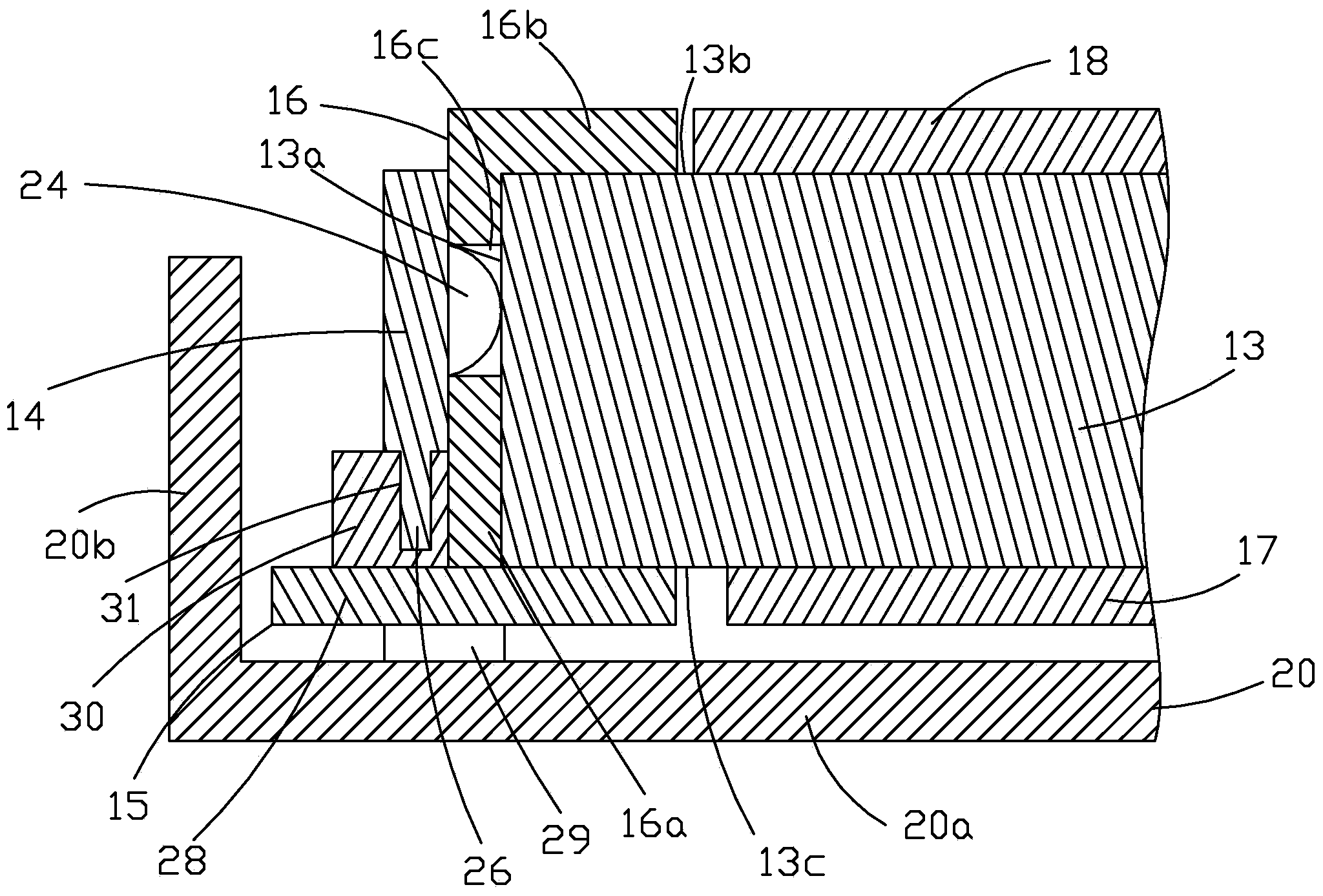

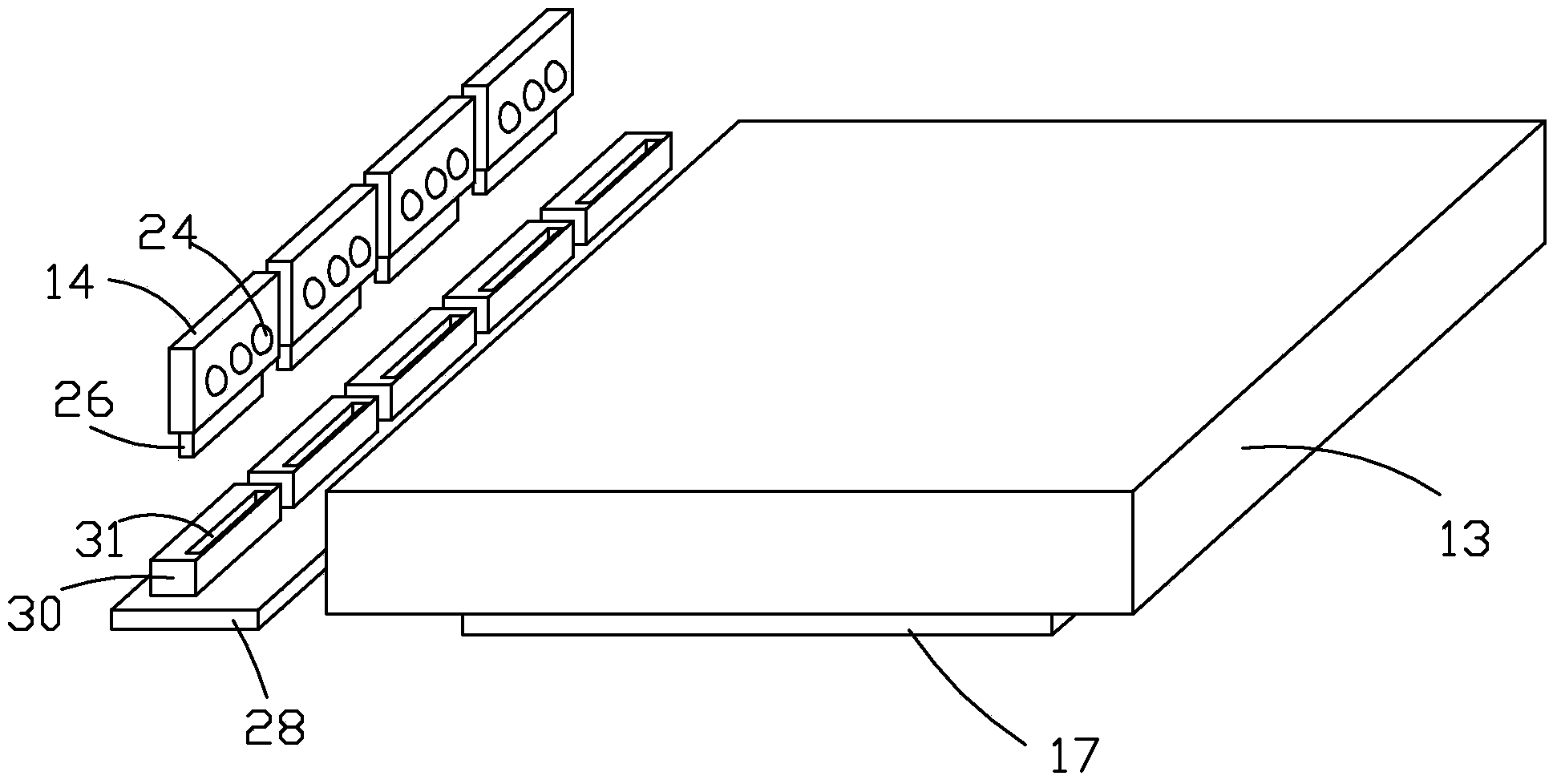

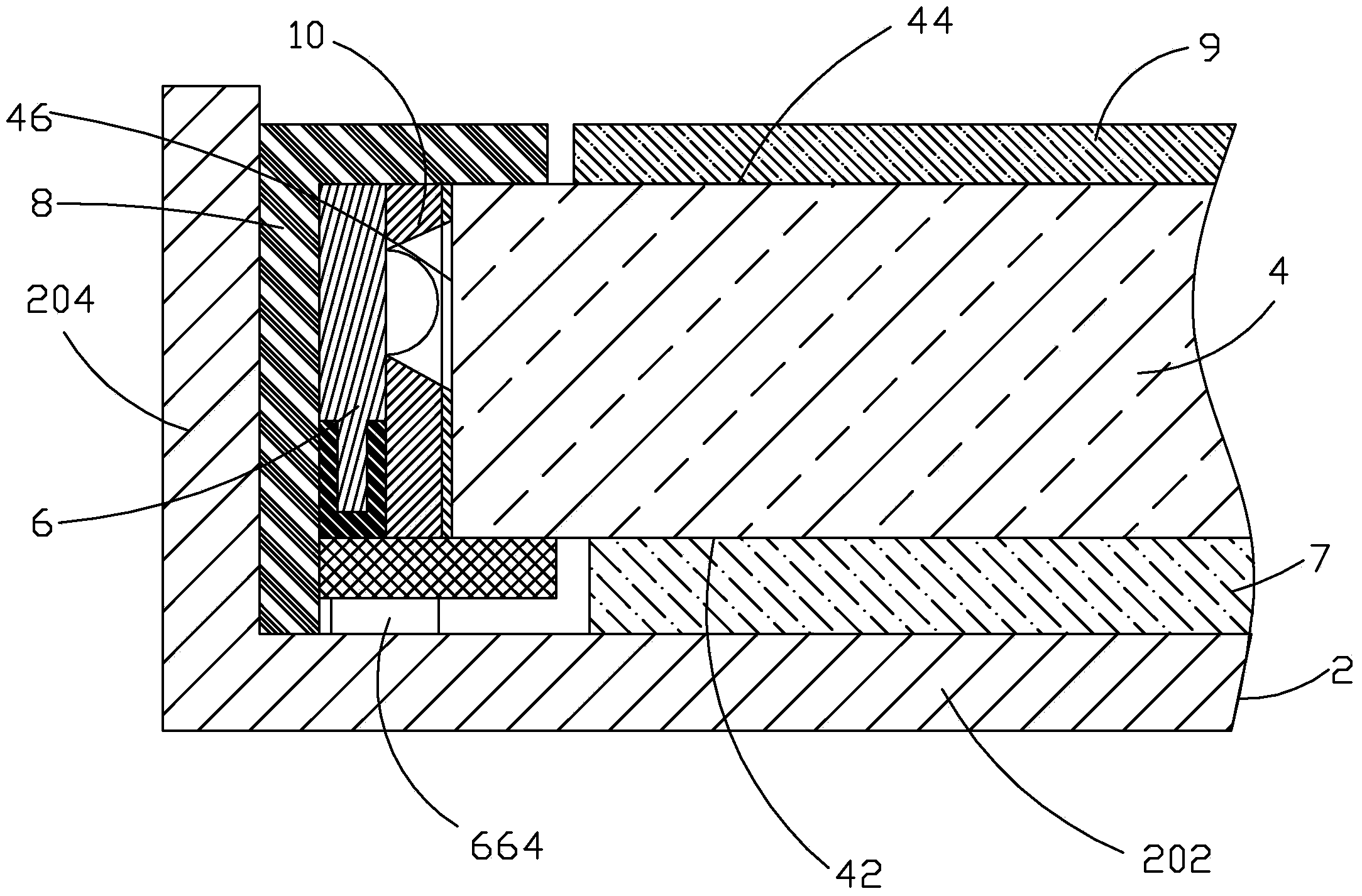

[0028] see image 3 , the present invention provides a backlight module, comprising: a backplane 2, a light guide plate 4 disposed in the backplane 2, a backlight source 6 disposed in the backplane 2 and located on one side of the light guide plate 4, a backlight source 6 disposed in the backlight 6 The shading cover 8 between the back plate 2 and the side reflector 10 arranged between the light guide plate 4 and the backlight 6, the light emitted by the backlight 6 directly enters the light guide plate 4 after being reflected by the side reflector 10, and Propagate in the light guide plate 4, and then transform the point light source into a surface light source.

[0029] Specifically, the back plate 2 includes a bottom plate 202 and several ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com