Plastic-lined socket and spigot coast iron pipe and manufacturing process thereof

A technology of cast iron pipe and socket type, which is applied to pipes, rigid pipes, pipes/pipe joints/fittings, etc. It can solve the problems of increased pipe weight, difficult manufacturing, complex equipment, etc., and achieves improved physical performance and product quality. Simple structure and improved mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

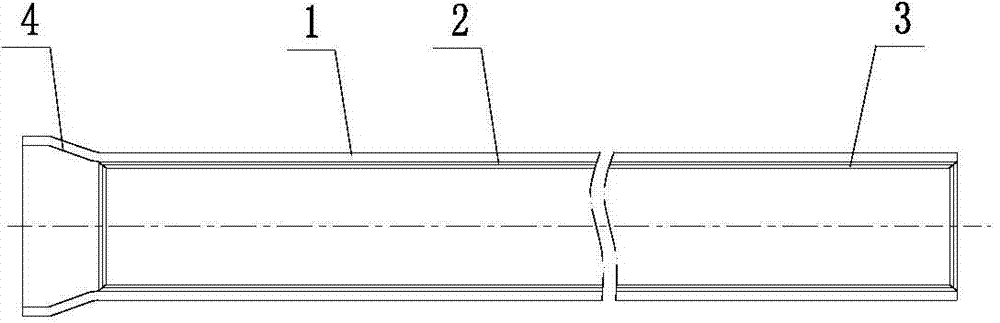

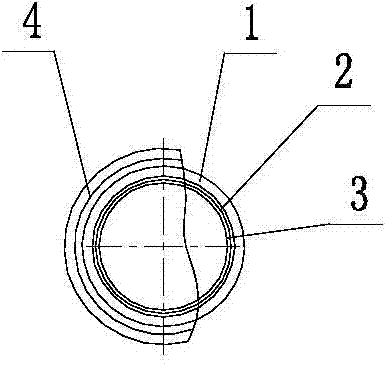

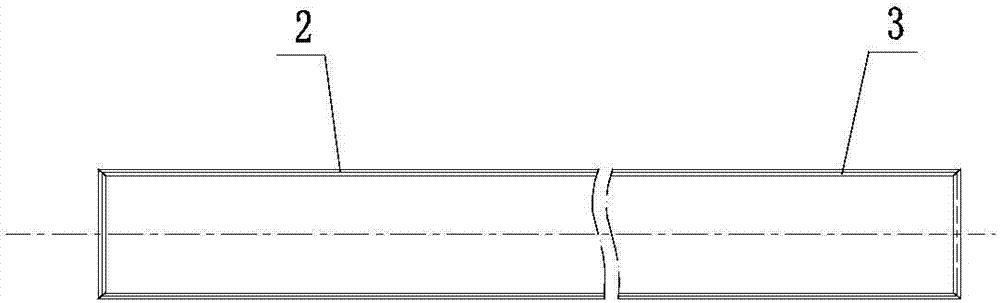

[0057]As shown in the accompanying drawings, a plastic-lined socket-type cast iron pipe includes a cast iron pipe 1 with a socket 4 at one end. In order to obtain better overall performance for the present invention, the cast iron pipe 1 adopts a ductile iron pipe 1, In order to improve the anti-corrosion performance of the cast iron pipe 1, the performance of water conveyance, the performance of water quality assurance, the performance of installation and maintenance, and the excellent cost performance, a lining plastic is added to the inner wall of the cast iron pipe 1, and the lining plastic includes the rubber layer 2 and the inner lining. 3.

[0058] In conjunction with the accompanying drawings, the rubber layer 2 and the inner liner 3 are produced on-line with a double-layer liner molded tire 20. The outer diameter of the double-layer lined molded tire 20 is slightly smaller than the inner diameter of the ductile iron pipe 1. The outer layer is a solid rubber layer, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com