Centrifugal compressor with vibratory diffuser blade

A centrifugal compressor and diffuser technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve problems such as restricting development and separation of flow channels, and achieve the goals of improving overall performance, optimizing structure, and reducing energy loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] In this embodiment, the overall oscillation of the blade is carried out by the vibrator:

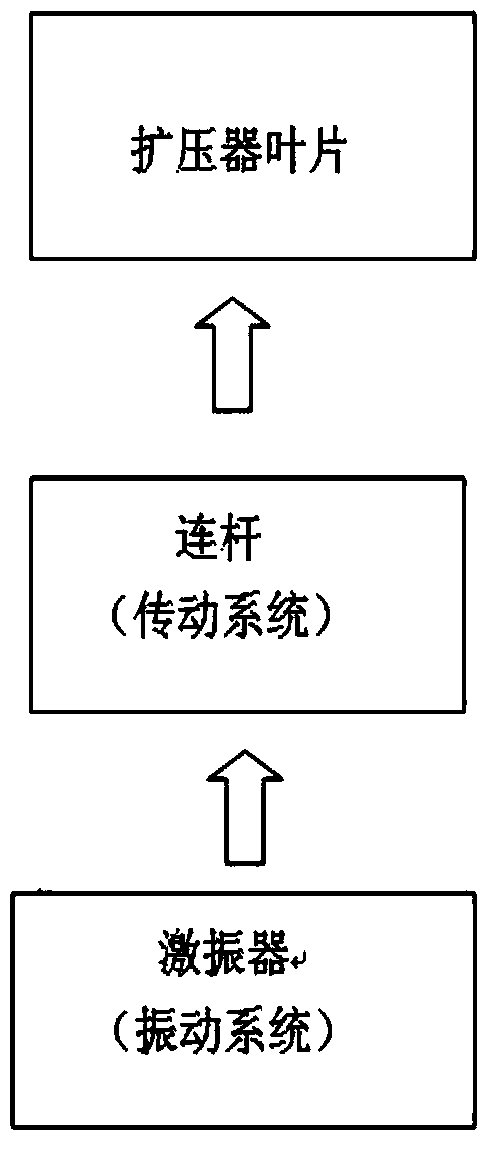

[0045] The exciter is connected with the diffuser blade through the transmission mechanism. When the exciter is working, it generates vibration and transmits it to the diffuser blade. The diffuser blade vibrates around the rotation axis of the diffuser blade. Take active control. As the main transmission mechanism, the connecting rod is arranged under the assembly hole of the diffuser blade, and the diffuser blade is connected with the vibration system through the transmission function of the connecting rod.

[0046] The amplitude of the exciter is 5mm, and the vibration frequency can vary from 0Hz to 200Hz. When the exciter is at a certain set excitation frequency, the excitation is transmitted to the blade through the connecting rod, so that the blade vibrates slightly around the assembly hole. Such as figure 1 , figure 2 shown. Through the reciprocating vibration of the ex...

Embodiment 2

[0048] In this embodiment, the overall oscillation of the blade is carried out through the elastic element:

[0049] The diffuser vane is connected with the elastic element through the transmission mechanism. When the gas flows through the diffuser, the diffuser vane generates self-excited oscillation, which realizes adaptive control of the internal flow field of the diffuser. The specific elastic element adopts a spring, and the connecting rod is arranged under the assembly hole of the diffuser blade as the main transmission mechanism, and the diffuser blade is connected with the vibration system through the transmission function of the connecting rod. Under the action of the incoming flow inside the diffuser, due to the strong fluid-solid coupling between the blades and the airflow in the diffuser, the deflection of the blades drives the connecting rod to rotate and deforms the spring system connected to the connecting rod, while the spring’s The deformation finally reacts o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com