Accessory gear train layout structure at front end of automobile engine

A technology for front-end accessories and gear trains, applied in the direction of machines/engines, mechanical equipment, etc., can solve the problems of waste of human resources in design and development costs, increase in the axial size of the engine, increase in engine costs and engine costs, and reduce manpower and development costs. wasteful, compact size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

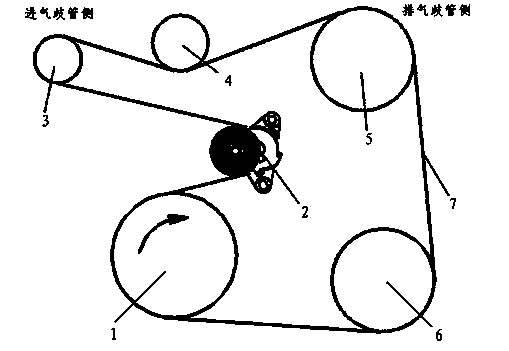

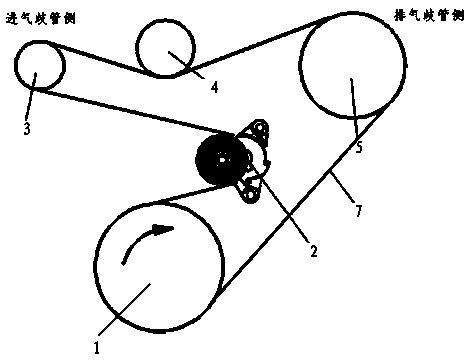

[0017] see figure 1 , an automobile engine front-end accessory gear train layout structure, which includes a crankshaft pulley 1, an automatic tensioner 2, an alternator pulley 3, an idler pulley 4, a water pump pulley 5, an air conditioner compressor pulley 6, and a V-ribbed belt 7. The air conditioner compressor pulley 6 and the water pump pulley 5 are respectively arranged on the same side of the crankshaft pulley 1, the alternator pulley 3 and the water pump pulley 5 are arranged above the crankshaft pulley 1, and the alternator pulley 3 is located on the intake On the manifold side, the water pump pulley 5 and the air conditioner compressor pulley 6 are located on the exhaust manifold side, the air conditioner compressor pulley 6 and the alternator pulley 3 are arranged on both sides of the crankshaft pulley, and the automatic tensioner 2 Located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com