Automobile exhaust treater

A technology of automobile exhaust and processor, which is applied in exhaust devices, machines/engines, chemical instruments and methods, etc., and can solve problems such as increasing exhaust resistance, poor exhaust of automobiles, environmental hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

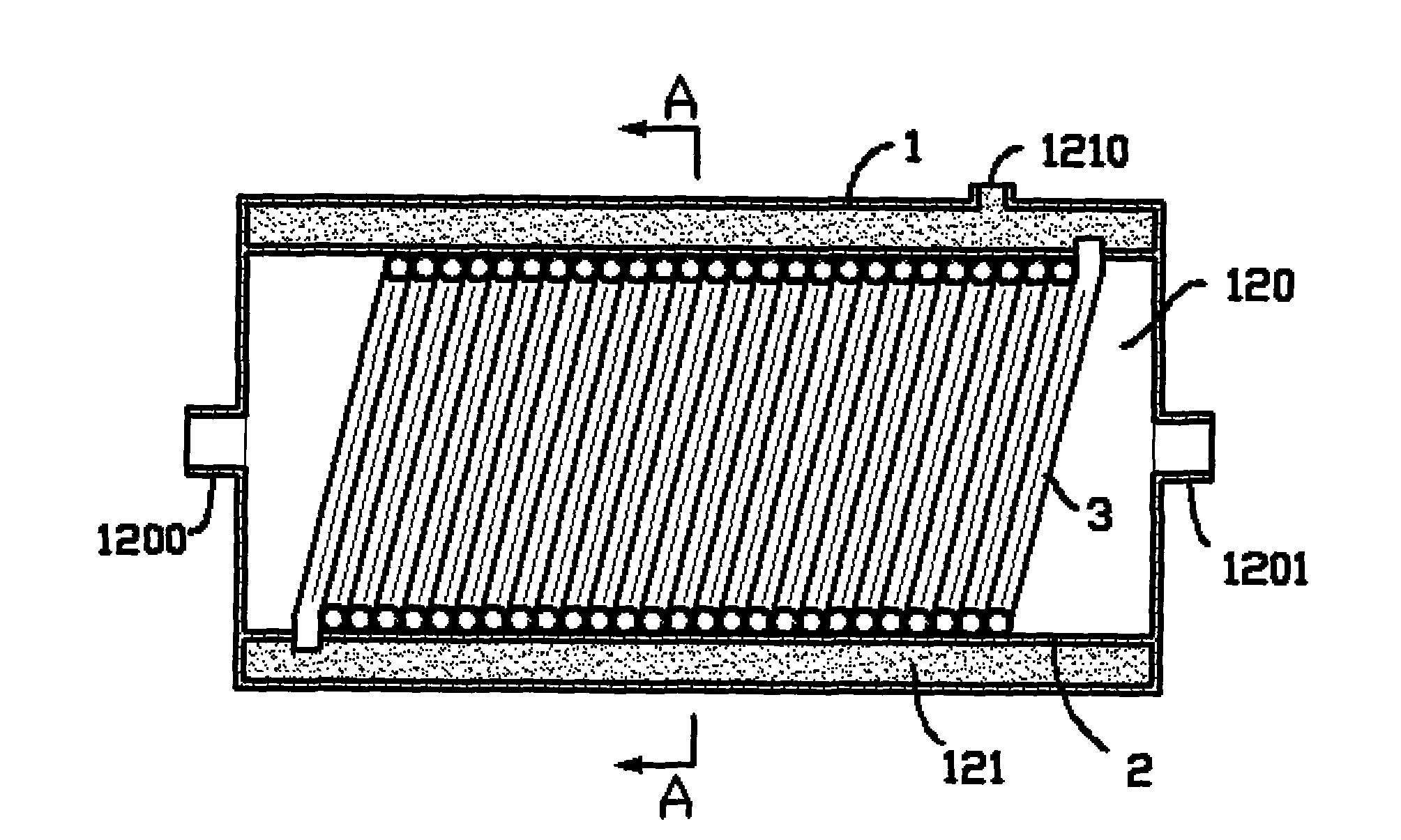

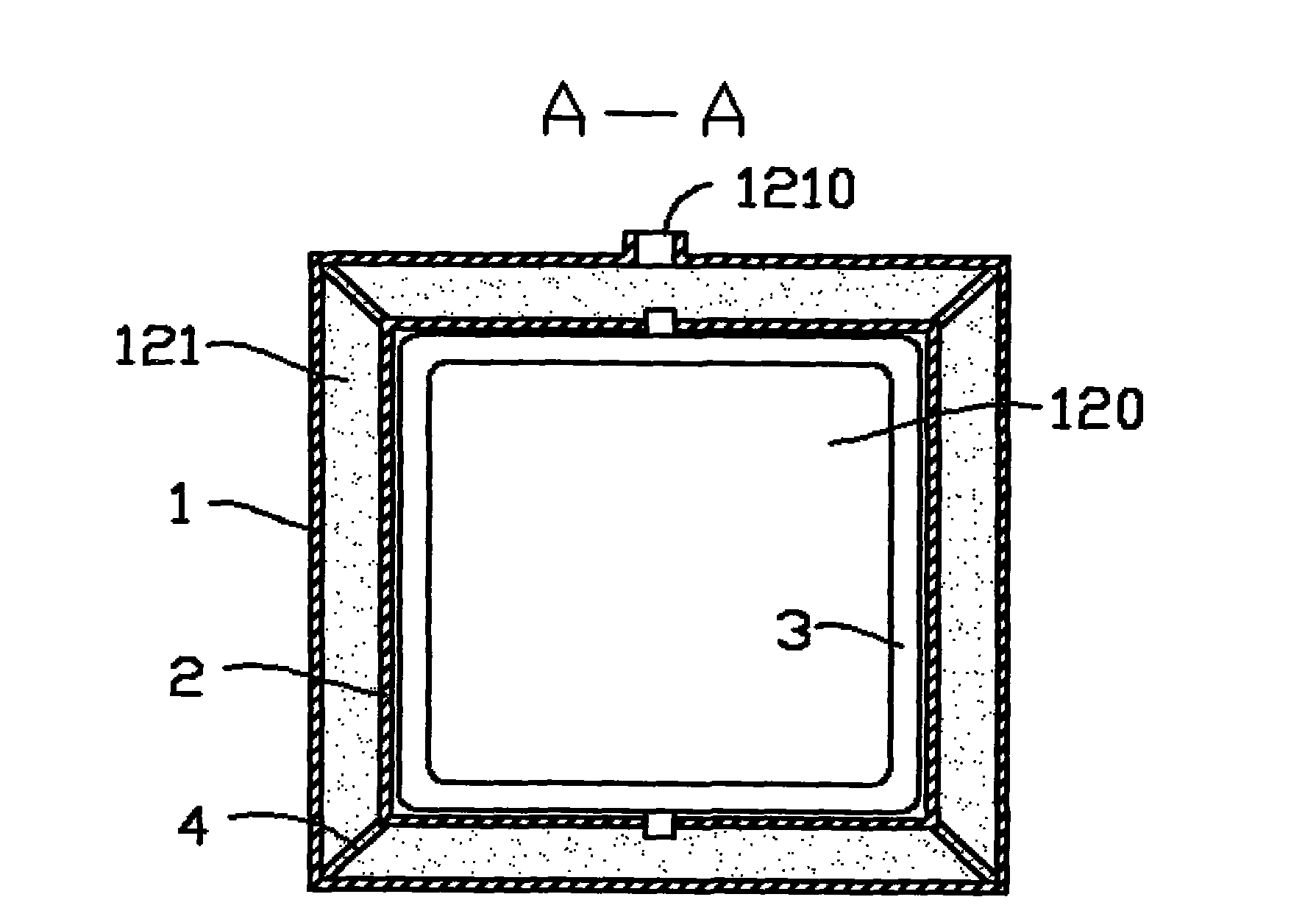

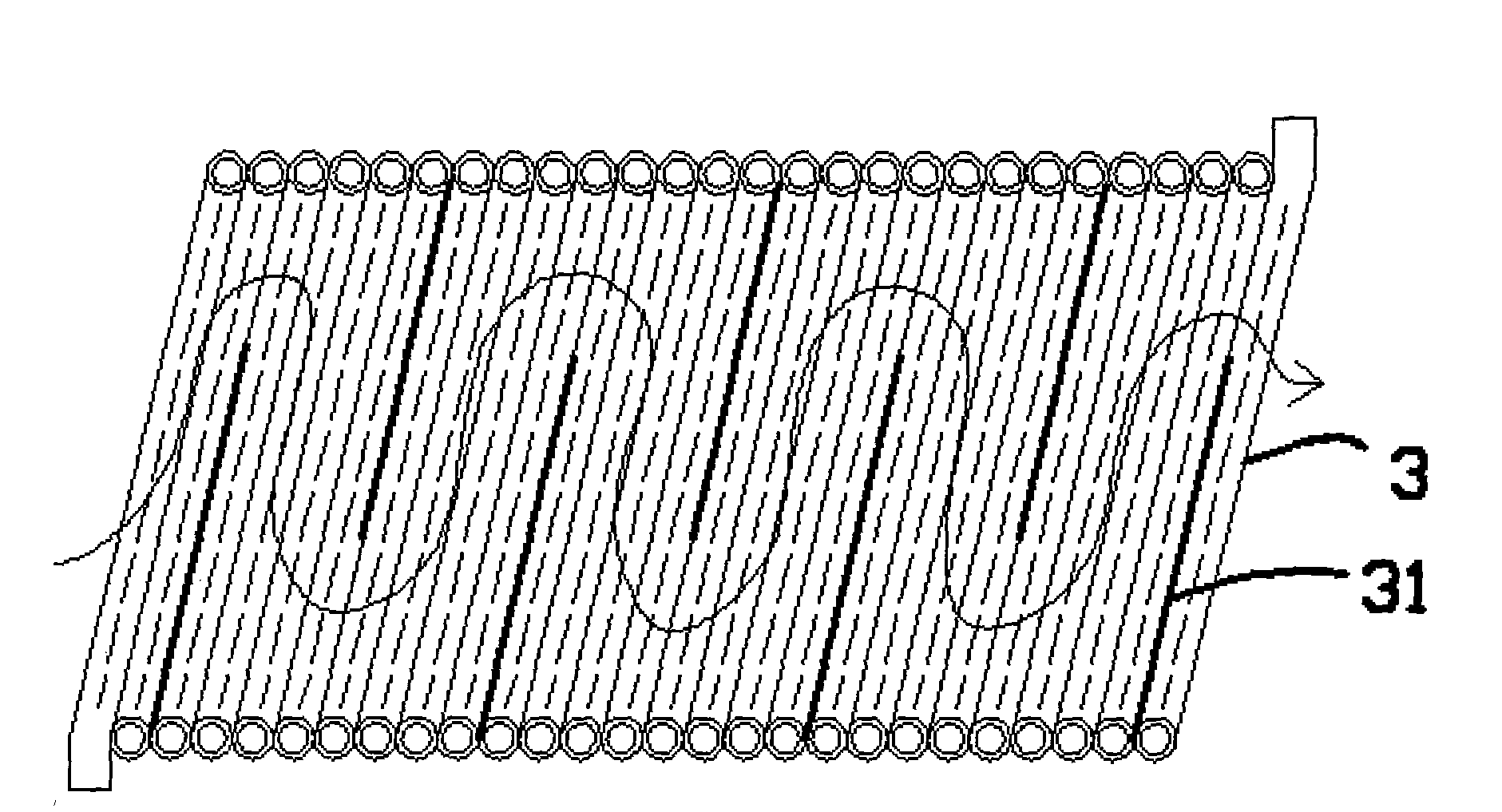

[0020] figure 1 , figure 2 Shown is the first embodiment of the automobile exhaust processor, wherein the automobile exhaust processor includes an exhaust chamber 120 surrounded by the outer shell 1 and the inner shell 2; the liquid storage chamber is between the outer shell 1 and the inner shell 2 121, and a support plate 4 is also provided between the outer shell 1 and the inner shell 2. The setting of the support plate 4 needs to ensure that the interior of the liquid storage chamber 121 is connected everywhere; A filter frame 3 made of a thin-walled metal tube, and the thin-walled metal tube of the filter frame 3 communicates with the liquid storage chamber 121; the surface of the thin-walled metal tube is provided with continuous slits along the longitudinal direction of the metal tube; The carbon dioxide treatment liquid is stored in the liquid storage chamber 121; the casing 1 is provided with a liquid injection port 1210 leading to the liquid storage chamber; the two...

Embodiment 2

[0024] Figure 4 Shown is the cross-sectional schematic diagram of the second embodiment of the automobile exhaust processor, which is different from the first embodiment in that: the inner side of the filter frame 3 also includes criss-crossing, which is also composed of the thin-walled metal tubes. The pipe 30, the supplementary pipe 30 communicates with the thin-walled metal pipe forming the outline of the filter frame 3, so as to increase the evaporation area of the carbon dioxide treatment liquid.

[0025] In addition, as a preferred mode of the automobile exhaust processor, the carbon dioxide treatment solution can be calcium hydroxide solution or sodium hydroxide solution, which is cheap and easy to replenish.

[0026] In this automobile exhaust processor, due to the thermal expansion and contraction effect of the thin-walled metal pipe forming the filter frame 3, when the automobile is not working, the exhaust pipe is in a low temperature state, and the slits of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com