A four-stage compression packer suitable for high temperature and high pressure construction conditions

A compression packer, high temperature and high pressure technology, applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problem that the packer cannot meet the construction requirements, and achieve strong shear resistance , Strong practicability, and the effect of large seat sealing force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

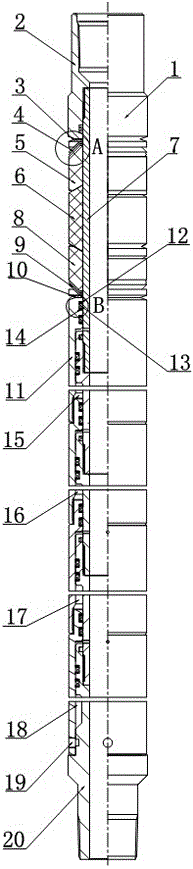

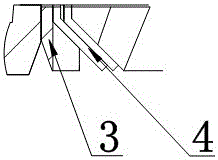

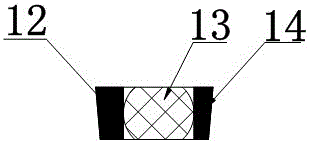

[0025] Such as Figure 1~3 As shown, the present invention includes a packer main body 1, a rubber cartridge protection mechanism and an auxiliary sealing device. The main body 1 of the packer is the same as the existing packer, and mainly consists of an upper joint 2, a rubber cylinder 6, a central pipe 7, a cylinder liner 11, a first-stage piston 15, a second-stage piston 16, and a third-stage piston. 17. The fourth-stage piston 18, the shear pin 19, the lower joint 20 and at least two sealing rings 13 are formed, such as figure 1 shown. When the central pressure is applied, the four-stage piston simultaneously pushes up the compression rubber cylinder 6 to realize the seat seal, and since there is no locking mechanism, the packer can realize automatic unsealing under the action of the elastic force of the rubber cylinder 6 after the pressure is released .

[0026] The rubber cartridge 6 is used to seal the packer when it is compressed, so as to ensure the pressure differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com