Combined-type mine drill rod

A combined drill pipe technology, which is applied in the direction of drill pipe, drill pipe, drilling equipment, etc., can solve the problems of time-consuming, labor-intensive, time-consuming and manpower-consuming, and large application, so as to increase economic benefits, easy loading and unloading, and not easy to fall off Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

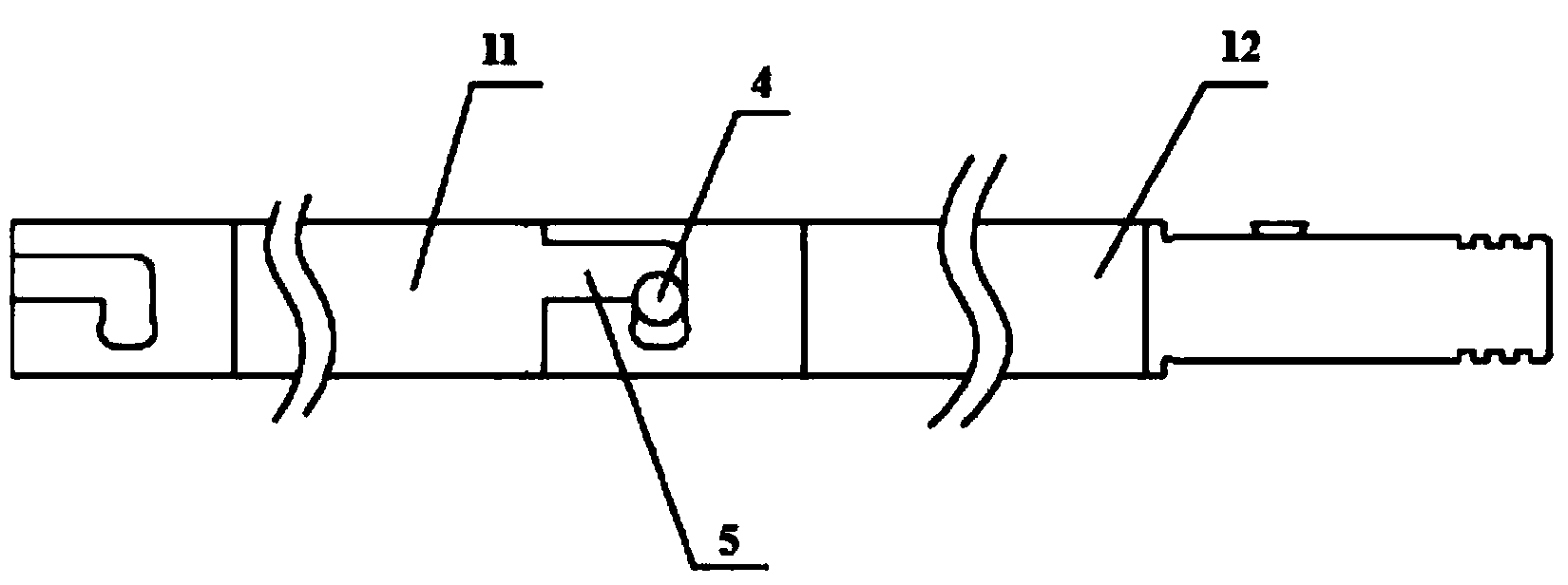

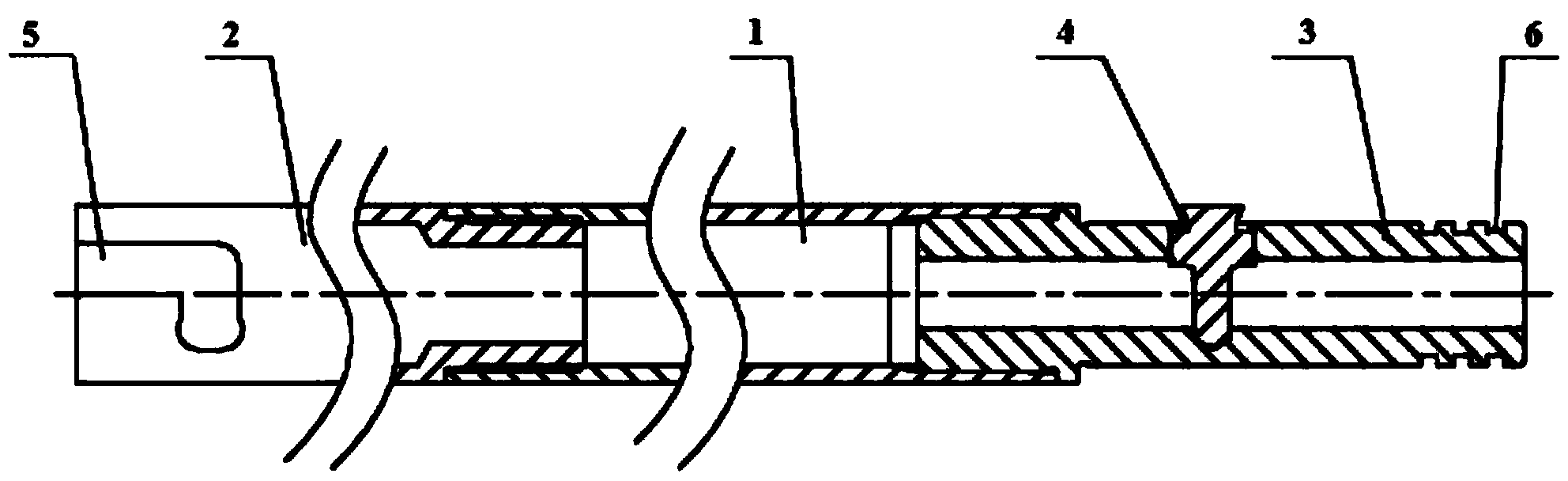

[0015] Such as figure 1 and figure 2 As shown, a combined mining drill pipe is composed of a plurality of drill pipe assemblies connected together. The drill pipe group includes a drill pipe body 1, a female joint 2, a male joint 3, and a pin 4. The drill pipe body 1 It is a hollow columnar structure with threads at both ends; the female joint is a hollow columnar structure with threads at one end, and is fixed to one end of the drill pipe body by threads, and the end away from the drill pipe body 1 is provided with L-shaped fixed block 5; the L-shaped fixed block 5 is composed of a slideway and a circular hole, the slideway is along the axial direction of the female joint 2, and the central axis of the slideway is formed by a line connecting the center of the circular hole right angle.

[0016] The male joint 3 is hollow and has ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com