Roofing method of double-layer anti-seepage drainer on the roof

A technology of anti-leakage and drainer, which is applied in the direction of roof drainage, roof covering, building roof, etc., can solve the problems of difficult to ensure gas discharge, increase cost and labor, and affect the service life of houses, so as to save raw materials of elbow pipes Cost and measure cost, high construction efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

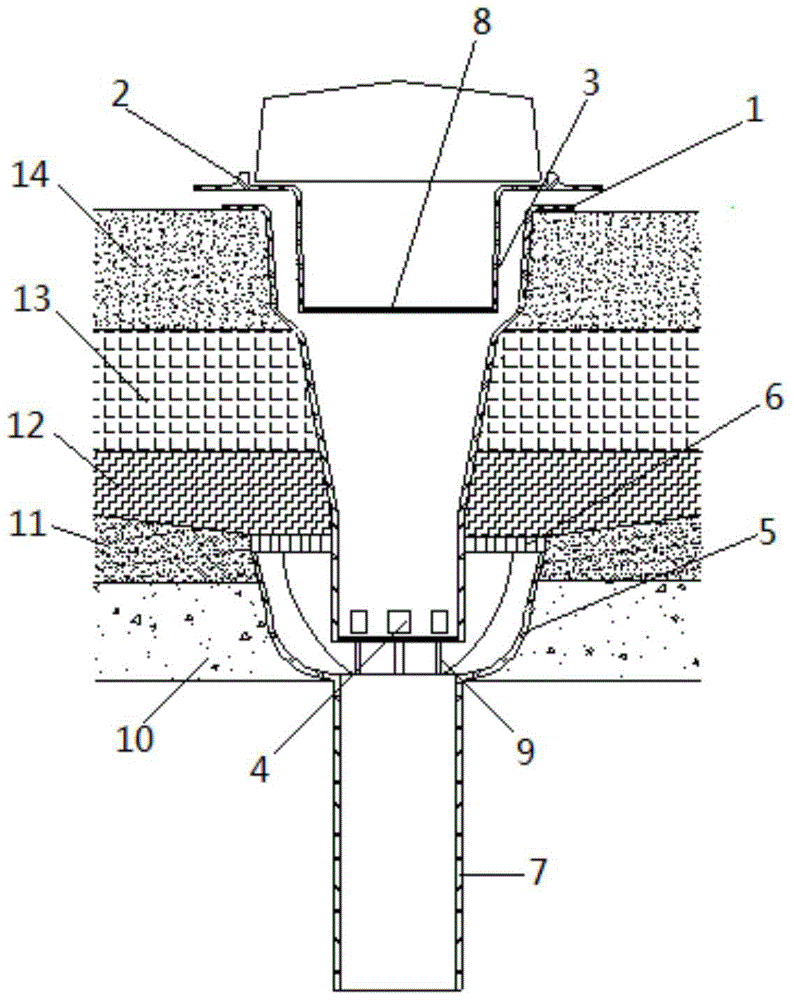

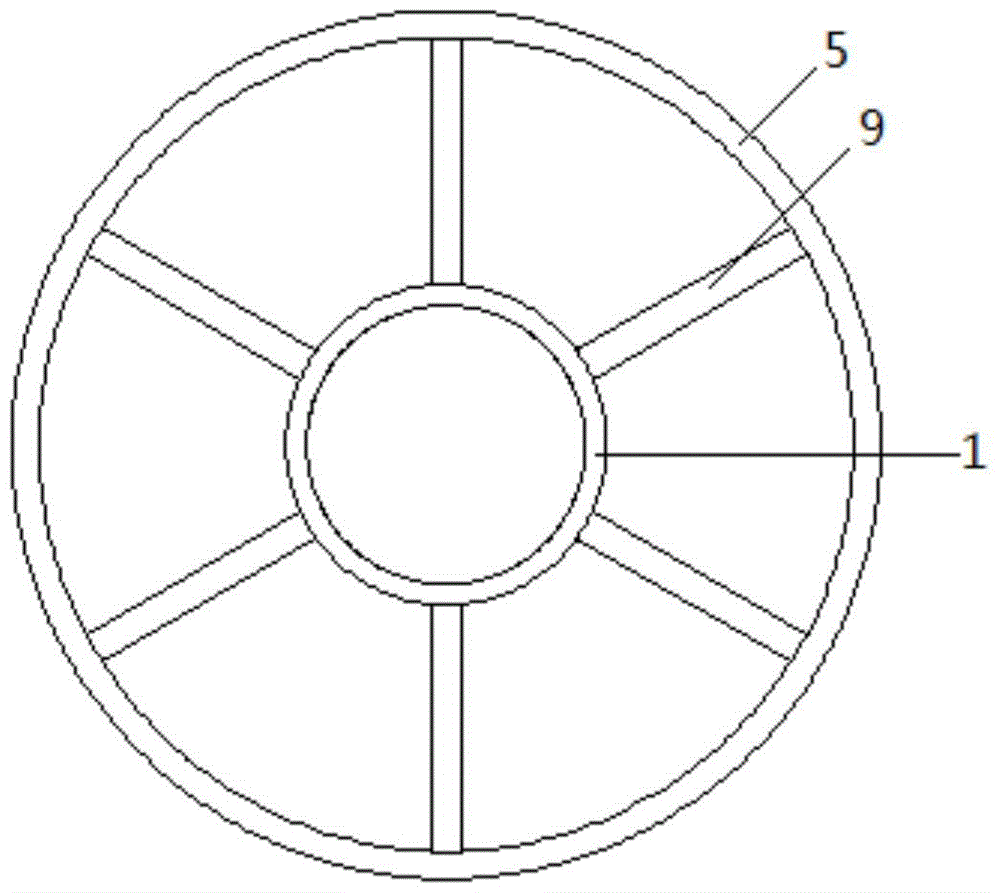

[0012] Referring to the accompanying drawings, the roof double-layer anti-seepage drainer includes a drainage floor drain 1, the upper mouth of the drainage floor drain 1 is equipped with an upper filter screen 3 through the pressure plate 2, the lower mouth of the drainage floor drain 1 is sealed, and there are some even holes on the side wall. Arranged leaking outlet 4, the lower end of drainage floor drain 1 is located in the outer drain 5, and is connected to the outer drain 5 through a partition 9, the mouth of the outer drain 5 is provided with a lower filter 6, and the outer drain 5. The lower part is connected to the sewer pipe 7, and the upper filter screen 3 is pipe-shaped, and the bottom is provided with a baffle plate 8.

[0013] The roofing method of the double-layer anti-seepage drainer on the roof includes the roof, and the roof is sequentially composed of a roof structure board 10, a waterproof protection layer 11, a hydrophobic layer 12, a mortar protection lay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com