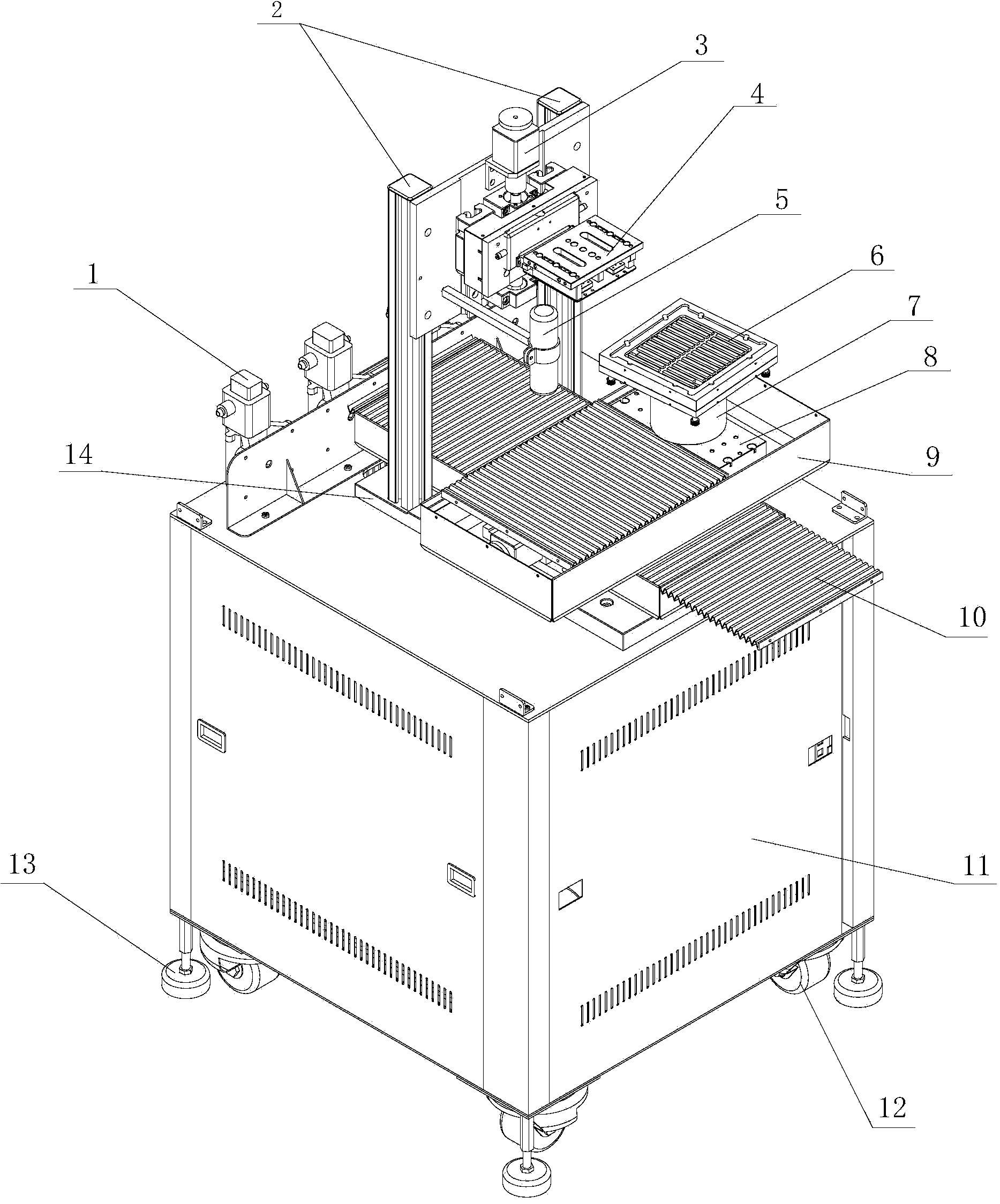

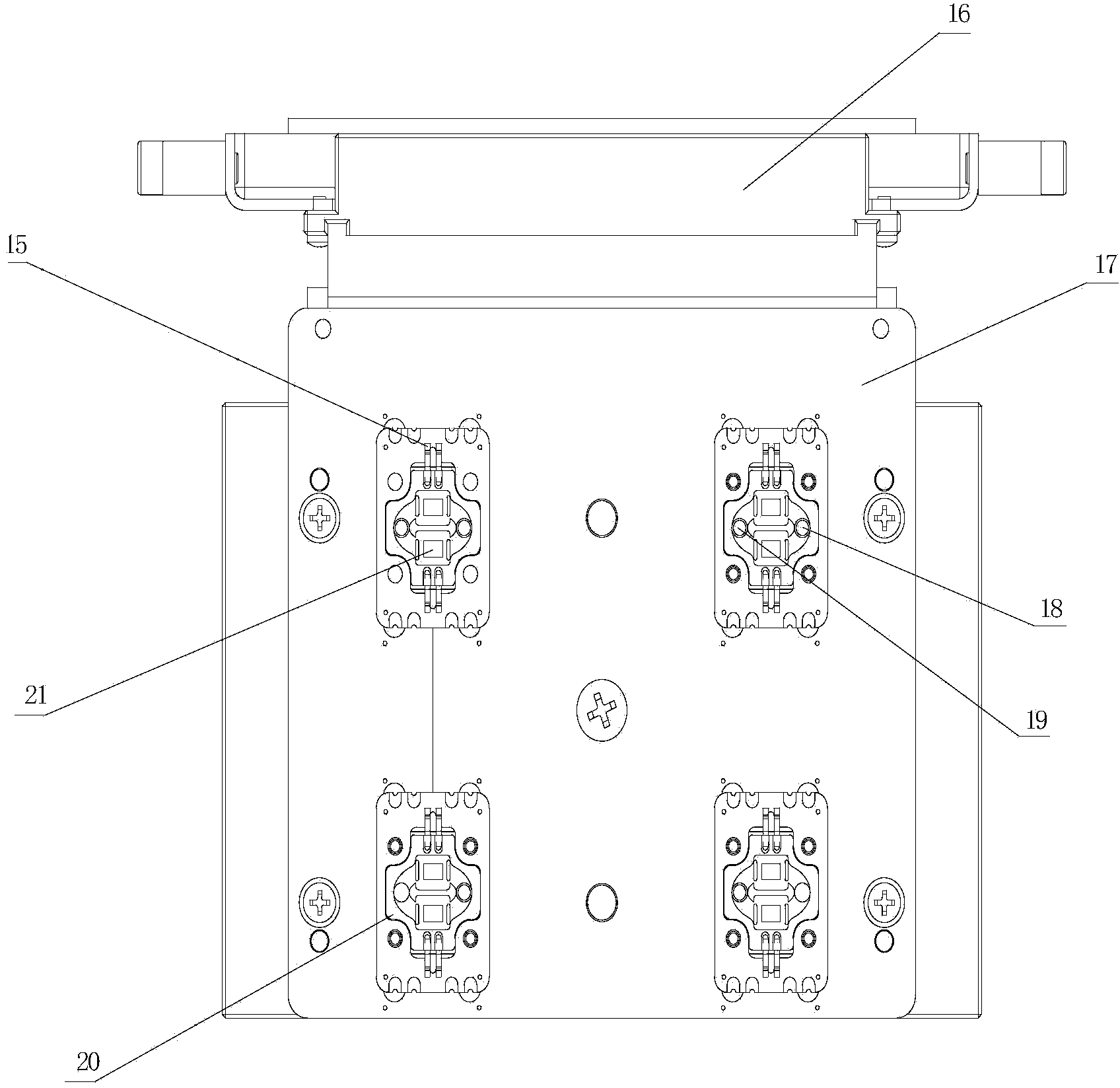

Automatic resistance adjusting device for resistance strain gauge and resistance adjusting method

A technology of resistance strain gage and strain gage is applied in the field of automatic resistance adjustment device of resistance strain gage, which can solve the problems of high labor intensity, great influence on the sensitive quality of the strain gage, low resistance adjustment efficiency, etc., and achieves high equipment control accuracy and improved Resistance stability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Electrochemical resistance adjustment is caused by the direct electrochemical reaction between the metal surface and the surrounding medium. Its principle is: the metal material will undergo a chemical reaction in a solution of certain active cations and anions. When the activity of these cations or anions is much greater than When the atomic charges of the metal are charged, they will migrate and replace each other. If two metals are added to the ionic solution, the atomic activity of the two metals has a certain potential difference. At this time, a positive voltage is applied to the metal with higher activity, and a negative voltage is applied to the other metal to form a potential difference. By adjusting the metal The distance and voltage difference between the plates will form electron migration, which will drive the migration of atoms, so that the metal atoms with high reactivity will migrate to the cathode plate, so that the anode plate will be thinned or reduced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com