A process for eliminating red smoke from waste acid regeneration unit

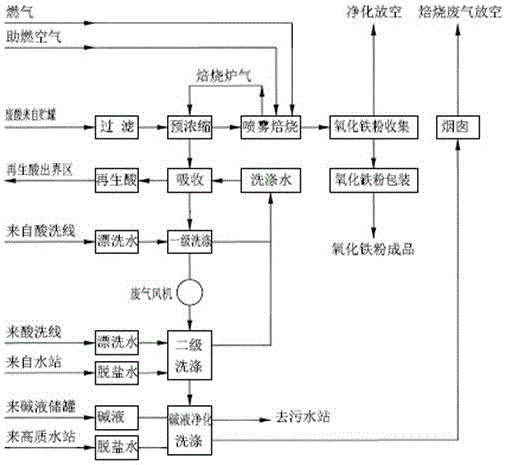

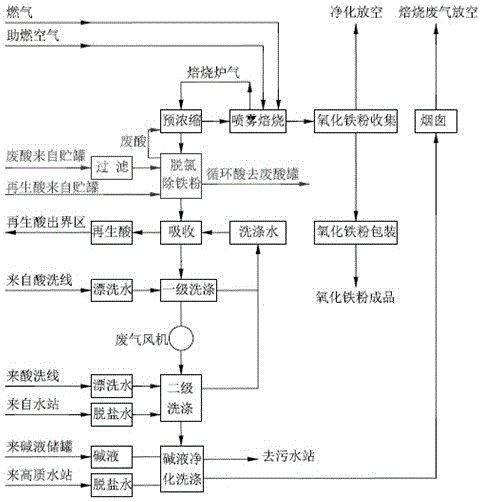

A technology of regeneration device and red smoke is applied in the technical field of eliminating red smoke from waste acid regeneration device, and can solve the problem of "red smoke from waste acid regeneration device".

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

comparative approach 1

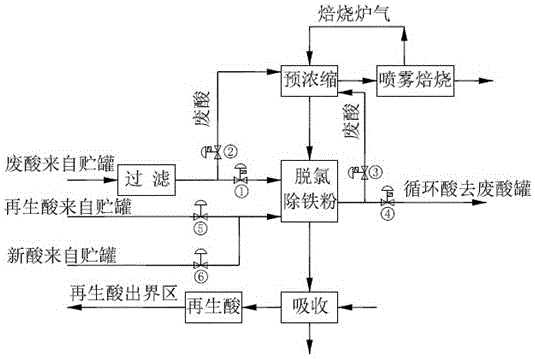

[0040] Supplementary acid comparison scheme 1: 18% regenerated acid is used for replacement. If the replacement is 10m3 / h per hour, it takes 82 minutes when the HCl concentration reaches 11.39%; when the HCl concentration reaches 14.21%, it takes 178 minutes. That is, in order to reach the standard HCl concentration and completely eliminate the phenomenon of red smoke, it takes too long for the dechlorination tower to reach the required concentration before the conversion operation.

comparative approach 2

[0041] Supplementary acid comparison scheme 2: If 18% regenerative acid is used for replacement, 25m per hour 3 / h, it takes 71min when the HCl concentration reaches 14.21%.

comparative approach 3

[0042] Supplementary acid comparison scheme 3: use 31% new hydrochloric acid, use 15m 3 / h for replacement, it takes 27min when the concentration of HCl reaches 14.21%; with 10m 3 / h for replacement, it takes 40 minutes for the HCl concentration to reach 14.21%.

[0043] From the above, it can be seen that using new hydrochloric acid (31% HCl new acid) as supplementary acid to supplement the dechlorination tower, when the concentration of hydrochloric acid in the dechlorination tower reaches the standard, the time spent is the shortest.

[0044] Secondly, after the concentration of HCl in the new circulating liquid in the dechlorination tower reaches 14% or more (it takes about 27 minutes), stop adding new hydrochloric acid and switch to supplementing regeneration acid; at this time, the preconcentrator directly enters the filter After the waste acid enters the dechlorination tower, it forms a circulating acid (liquid) and then goes to the waste acid tank; the specific operati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com