Method for nickeling carbon fiber/cyanate ester resin composite material

A cyanate resin and composite material technology, which is applied in metal material coating process, liquid chemical plating, superimposed layer plating, etc. The effect of low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

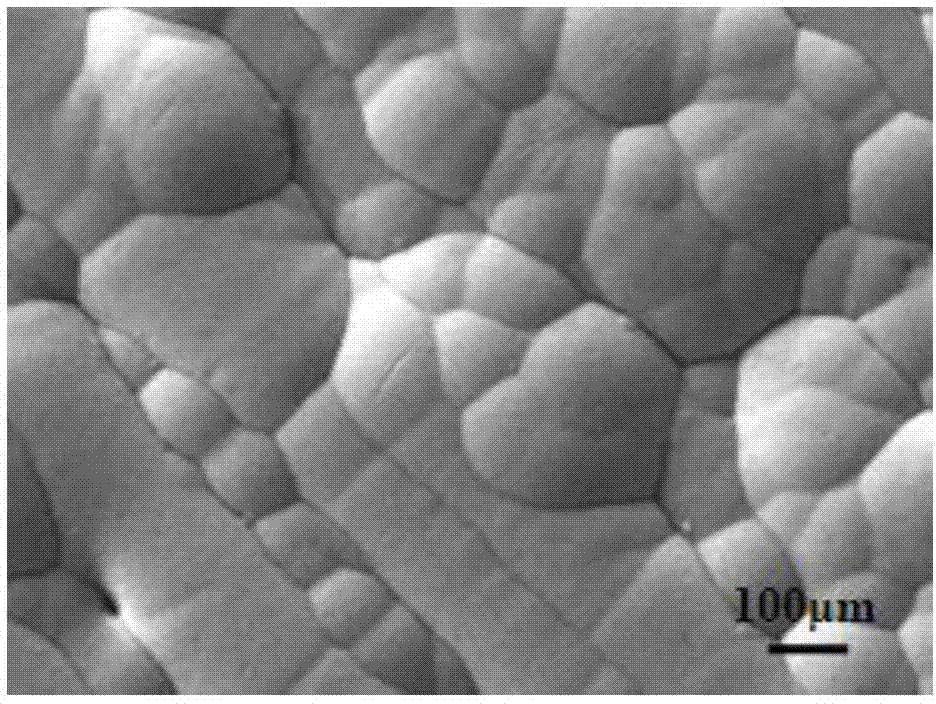

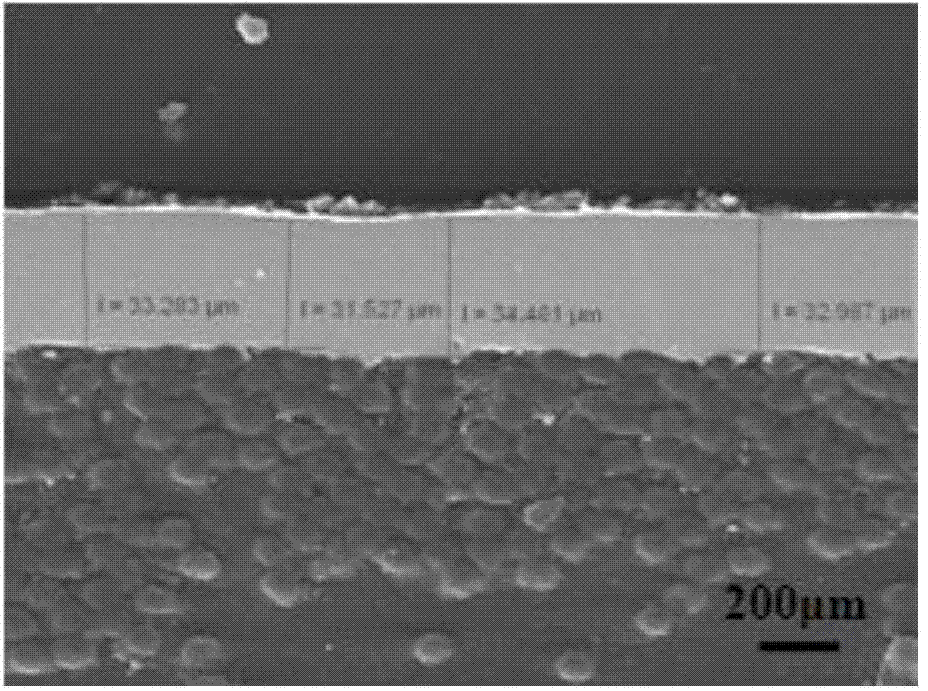

Embodiment 1

[0042] Using 25mm×25mm×5mm carbon fiber / cyanate resin composite plate; the plating area is 0.175dm 2 , the loading of the plating solution refers to the ratio of the plating area of the workpiece to the volume of the plating solution, and the loading of the plating solution is 0.5dm 2 / L to calculate the required volume of electroless plating solution and electroplating solution are 350mL.

[0043] Step 1, pre-processing,

[0044] a. Degreasing: Soak the carbon fiber / cyanate resin composite material in 350mL acetone, take it out after ultrasonication for 20min, wash it with distilled water, and dry it;

[0045] b. Coarsening: Soak the material obtained in step a in 350mL of 35% nitric acid, heat it in a water bath to 40°C, keep it warm for 20min, wash it with distilled water, and dry it;

[0046] c. Sensitization: Dissolve 5.25g of stannous chloride in 14mL of concentrated hydrochloric acid, add 7g of tin particles, dilute to 350mL with distilled water to obtain a sensitiz...

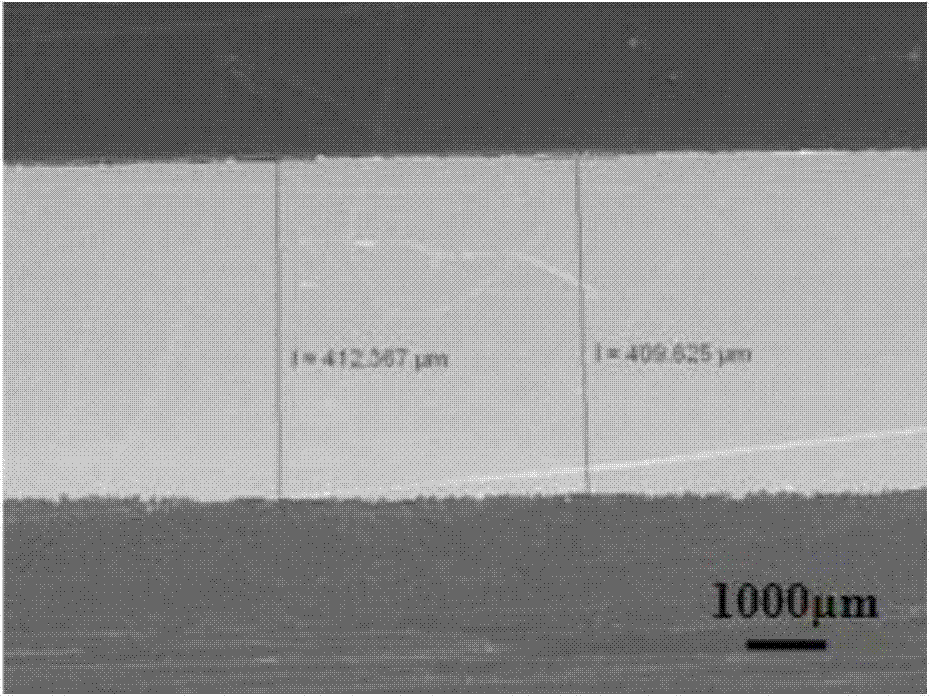

Embodiment 2

[0057] Carbon fiber / cyanate resin composite plate with diameter d=130mm and thickness t=5mm is used; the plating area is 2.86dm 2 , the loading of the plating solution refers to the ratio of the plating area of the workpiece to the volume of the plating solution, according to the loading of the plating solution is 1.43dm 2 / L calculates that the volumes of both the electroless plating solution and the electroplating solution are 2L.

[0058] Step 1, pre-processing,

[0059] a. Degreasing: Soak the carbon fiber / cyanate resin composite material in 2L of acetone, take it out after ultrasonication for 15min, wash it with distilled water, and dry it;

[0060] b. Coarsening: Soak the material obtained in step a in 2L of 35% nitric acid, heat it in a water bath to 40°C, keep it warm for 15 minutes, wash it with distilled water, and dry it;

[0061] c. Sensitization: Dissolve 30g of stannous chloride in 80mL of concentrated hydrochloric acid, add 30g of tin particles, dilute to 2L...

Embodiment 3

[0071] Use 20mm×20mm×5mm carbon fiber / cyanate resin composite plate; the plating area is 0.12dm 2 , the loading of the plating solution refers to the ratio of the plating area of the workpiece to the volume of the plating solution, according to the loading of the plating solution is 1.2dm 2 / L to calculate the required volume of electroplating solution and electroplating solution are 100mL.

[0072] Step 1, pre-processing,

[0073] a. Degreasing: Soak the carbon fiber / cyanate resin composite material in 100mL of acetone, take it out after ultrasonication for 10min, wash it with distilled water, and dry it;

[0074] b. Coarsening: Soak the material obtained in step a in 100mL of 35% nitric acid, heat it in a water bath to 40°C, keep it warm for 18min, wash it with distilled water, and dry it;

[0075] c. Sensitization: Dissolve 1.5g of stannous chloride in 4mL of concentrated hydrochloric acid, add 1.8g of tin particles, dilute to 100mL with distilled water to obtain a sens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com