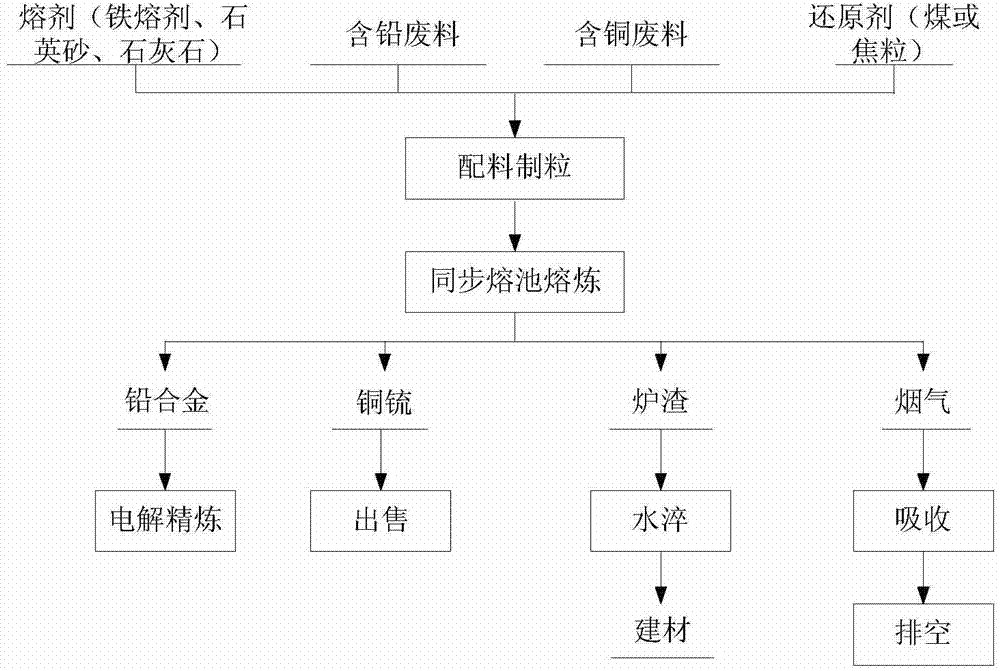

A method for synchronous molten pool smelting of lead-containing and copper-containing scrap

A molten pool smelting and copper scrap technology, applied in the field of synchronous extraction of heavy metals and pyrometallurgy, can solve the problems of low-value by-products, complicated operation, low efficiency, etc., and achieve the effect of low cost, simple processing and high added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Lead-containing waste is copper converter soot, and its composition is shown in Table 1:

[0035] Table 1 Main chemical composition of lead-containing waste (%)

[0036] Pb

Zn

Cu

CaO

FeO

SiO 2

S

38.77

4.68

0.95

0.74

2.16

2.81

6.42

[0037] Copper-containing waste is copper electroplating sludge, and its composition is as shown in Table 2:

[0038] Table 2 Main chemical composition of copper-containing scrap (%)

[0039] Cu

Fe

Ni

Zn

S

O

9.03

6.21

0.286

4.486

2.99

31.9

[0040] Water quenching slag contains Fe25.58%, SiO 2 22.6%, CaO21.3%.

[0041] Mix 100g of the above-mentioned lead-containing waste, 212g of copper-containing waste, 21.5g of quartz sand, 78.9g of iron flux, and 23g of anthracite, and then add a small amount of water to stir and granulate. For the charge. Among them, quartz sand contains SiO 2 96%, particle size 0...

Embodiment 2

[0045] The lead-containing waste is the lead sludge produced by the lead-zinc smelter, and its composition is shown in Table 3:

[0046] Table 3 Main chemical composition of lead-containing waste (%)

[0047] Pb

Zn

Cu

CaO

FeO

SiO 2

S

48.59

2.38

0.82

1.19

2.70

3.71

7.22

[0048] The copper-containing waste is copper smelting converter slag, and its composition is shown in Table 4:

[0049] Table 4 Main chemical composition of copper-containing scrap (%)

[0050] Cu

Fe

Pb

Zn

S

Al 2 o 3

CaO

6.80

32.64

1.26

6.5

1.8

5.4

2.5

[0051] Water quenching slag contains Fe25.58%, SiO 2 22.6%, CaO21.3%.

[0052] Mix 100g of the above-mentioned lead-containing waste, 64.51g of copper-containing waste, 10g of quartz sand, 26.4g of iron-containing flux, and 11.46g of coke particles, and then add a small amount of water to stir and granulate. %...

Embodiment 3

[0056] Lead-containing waste is waste lead-acid battery lead paste mud, and its composition is shown in Table 5:

[0057] Table 5 Main chemical composition of lead-containing waste (%)

[0058] Pb

Zn

CaO

SiO 2

S

75.2

13.26

0.25

0.04

4.75

[0059] The copper-containing waste is electro-zinc sewage treatment sludge, and its composition is as shown in Table 6:

[0060] Table 6 Main chemical composition of copper-containing scrap (%)

[0061] Cu

Fe

S

SiO 2

42.39

0.43

5.0

0.09

[0062] Water quenching slag contains Fe25.58%, SiO 2 22.6%, CaO21.3%.

[0063] Mix 100g of the above lead-containing waste, 30.45g of copper-containing waste, 16.5g of quartz sand, 38.79g of anthracite, and 9g of limestone. After fully mixing, add a small amount of water to stir and granulate. Control the particle size to 20-50mm and control the water content to 6-8%. Among them, quartz sand, conta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com