Anoxic bioreactor

A bioreactor and reactor technology, applied in the field of environmental protection, can solve problems such as high energy consumption and difficult industrialization, and achieve the effects of reducing fluidization energy consumption, being beneficial to industrialization, and optimizing mass transfer effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

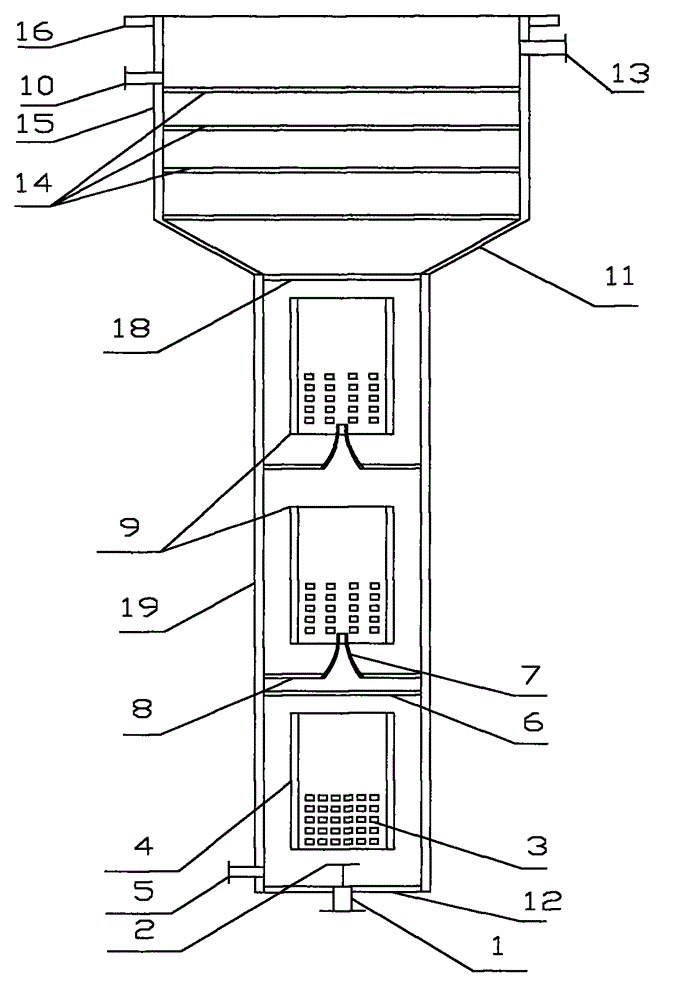

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings.

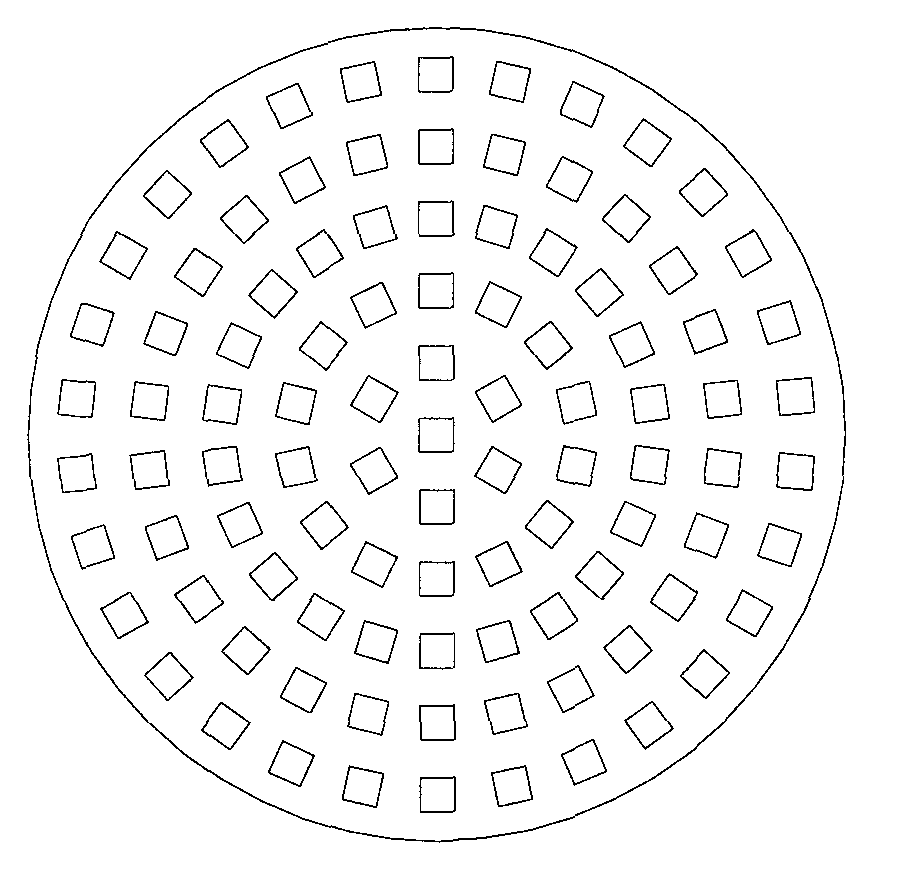

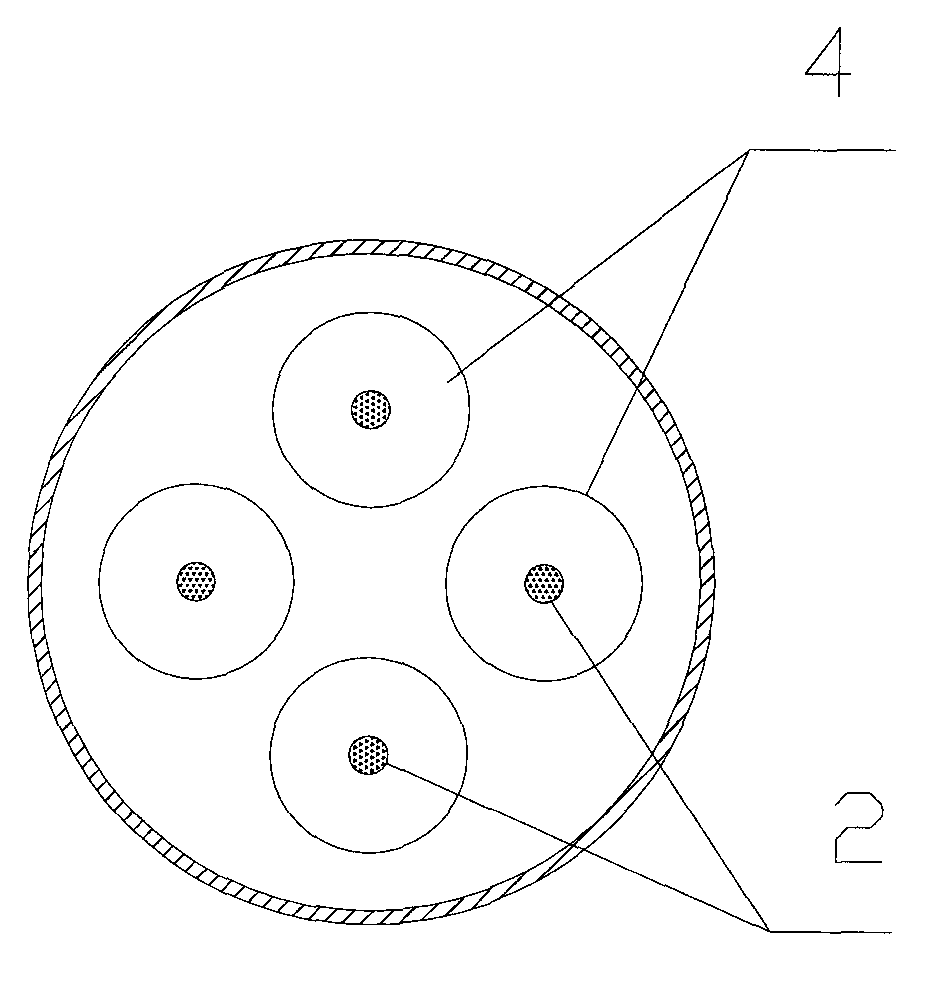

[0033] Such as figure 1As shown, the anoxic bioreactor provided by the present invention is divided into three parts: strong fluidization zone, weak fluidization zone, and mud-water separation zone from bottom to top; the strong fluidization zone and the weak fluidization zone share a lower outer cylinder 19. The strong fluidization zone is located in the lower part of the reactor. From bottom to top, there are sewage feed inlet 1, bottom plate 12, return inlet 5, gas-liquid two-phase nozzle 2, strong fluidization zone guide tube 4, biological carrier and The strong fluidization zone has a perforated tray 6, the sewage feed inlet 1 is located under the bottom plate 12 of the reactor, and is connected with the gas-liquid two-phase nozzle 2, and the return inlet 5 is located on the lower side of the lower outer cylinder 19, and the strong fluidization zone is The orif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com