Vertical pay-off brake device

A brake device and wire-releasing technology, which is applied in the directions of transportation and packaging, delivery of filamentous materials, thin material processing, etc., can solve problems such as scalding employees, hidden safety hazards, and affecting smooth production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

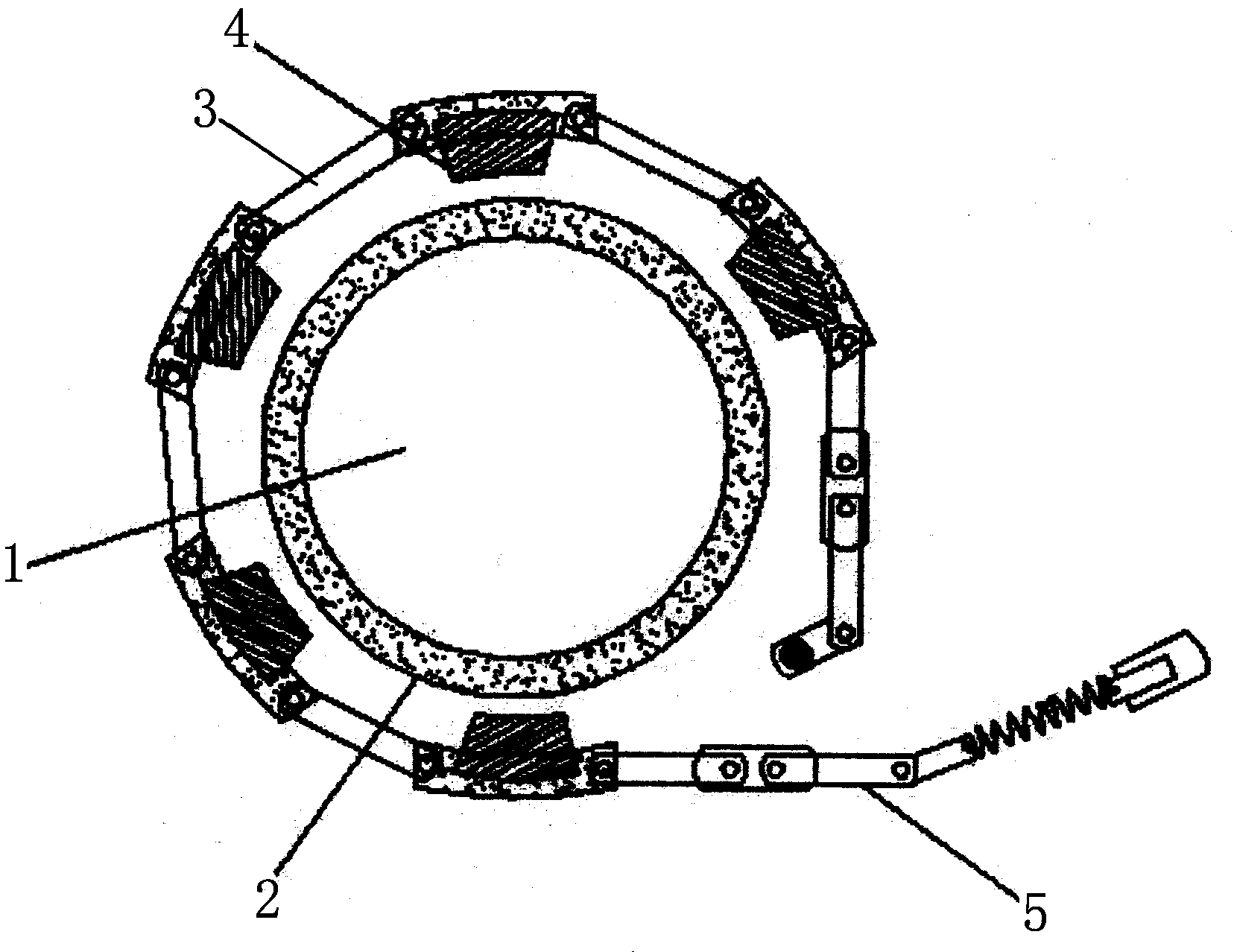

[0009] like figure 1 As shown, the present invention is provided with a brake sleeve 2 on the outer periphery of one end of the pay-off frame 1, a brake belt 3 is arranged on the outer periphery of the brake sleeve 2, and a plurality of brake pads 4 are arranged on the inner edge of the brake belt 3. 4. Corresponding to the brake sleeve 2, one end of the brake band 3 is fixed, and the other end is provided with a lever pressing mechanism 5. Through the above settings, the I-shaped wheel is installed on the rotating shaft of the pay-off frame 1 of the present invention, and the brake pad 4 is pressed against the brake sleeve 2. 4. Loosen the car to set the tension of the pay-off, which avoids the independent rotation of the I-shaped wheel due to inertia, realizes the smooth pay-off, and avoids the drop, disorder and extrusion of the I-shaped wheel pay-off.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com