Acquisition, verification, association and heat-sealing, film-cutting and film-wrapping mechanism of round bottle barcode packaging

A technology of heat-sealing and barcoding, which is applied in packaging, packaging protection, and wrapped objects, etc., can solve the problems of high risk of data association, low production efficiency, and direct error, etc., to eliminate danger sources, high production efficiency, and compact structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

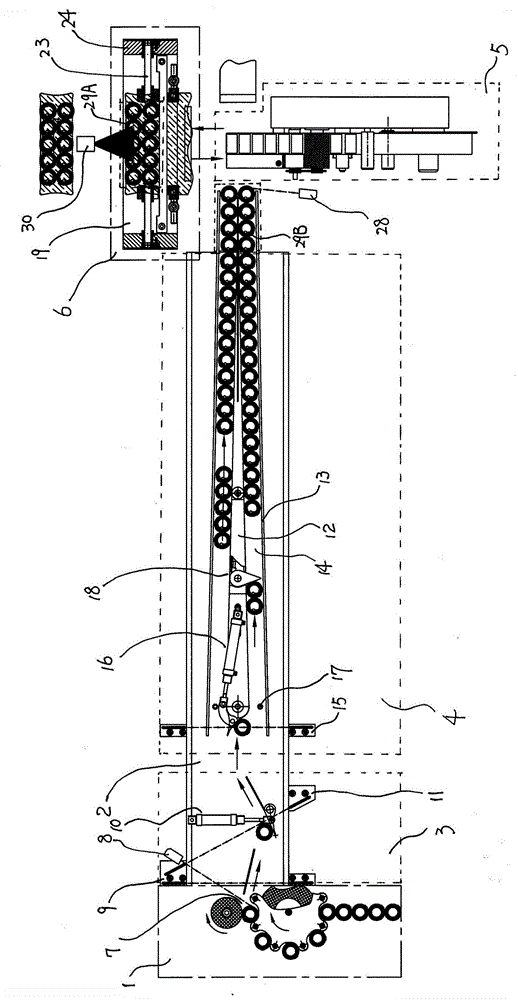

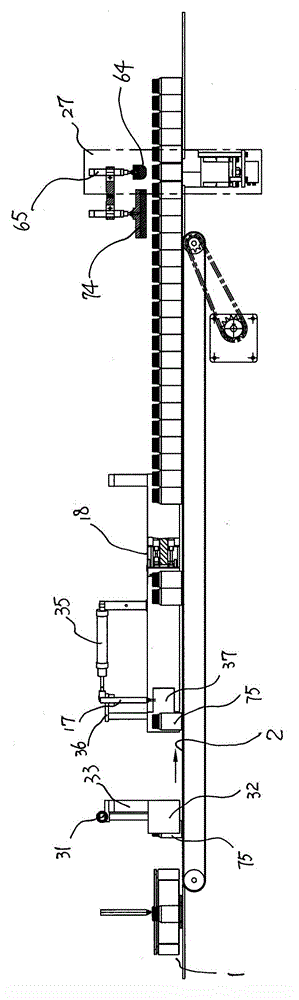

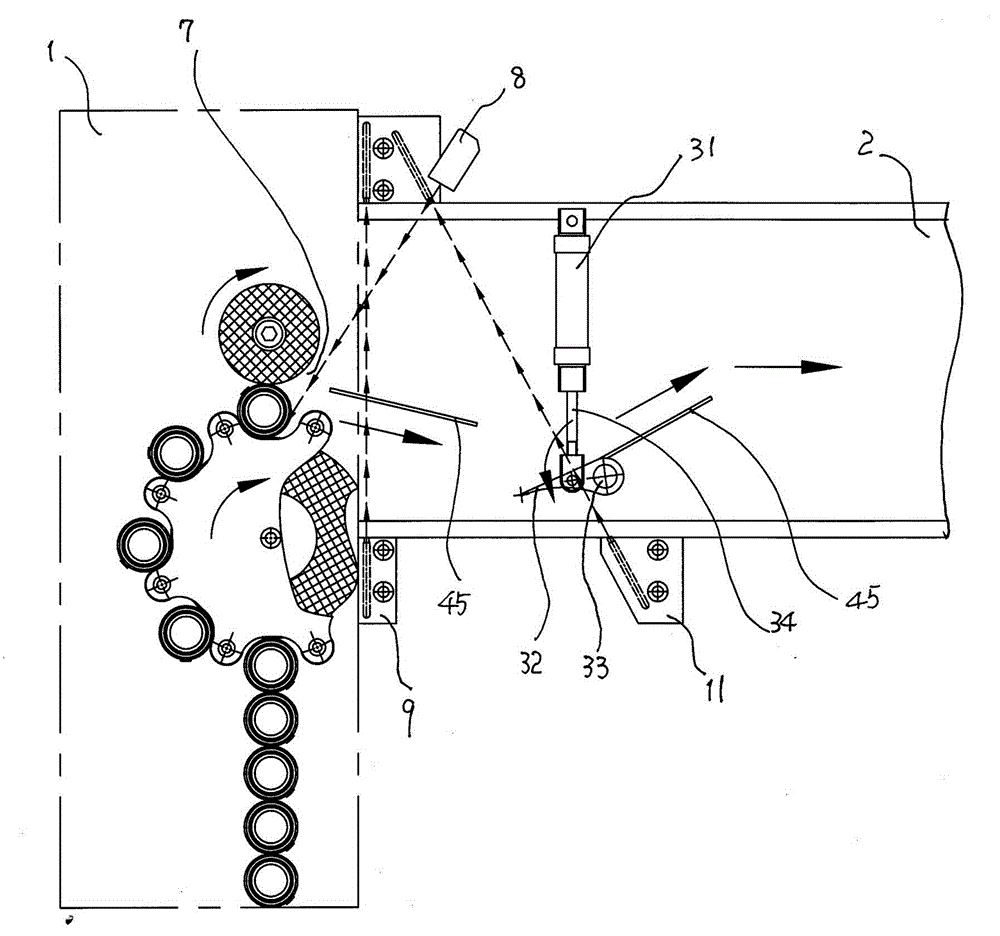

[0021]As shown in the figure, the present invention includes a rotary bottle feeding part 1, a conveyor belt 2, a barcode packaging removal part 3, a lane transfer part 4, a labeling part 5, and a heat sealing and film cutting part 6. The rotary bottle feeding part 1 is connected to the conveyor belt 2. In the barcode package rejecting part 3, a primary scanner 8 is installed relative to the rotating bottle part 7 of the rotating bottle feeding part 1, and a rejecting device 10 is arranged above the conveyor belt 2, and first Photoelectric switch 9, the rejecting action of the first photoelectric switch 9 controls rejecting device 10 to move to standby position by initial position, the second photoelectric switch 11 is set with respect to the standby position of rejecting device 10 rejecting action on both sides of conveyor belt 2, the second The photoelectric switch 11 controls the rejecting action of the rejecting device 10 to move from the standby position to the rejecting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com