Gilding press

A technology of hot stamping machine and hot stamping paper, which is applied to the hot stamping machine. It can solve the problems of complex and bulky structure, inconvenient operation and slow operation, and achieve the effect of good effect, convenient operation and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

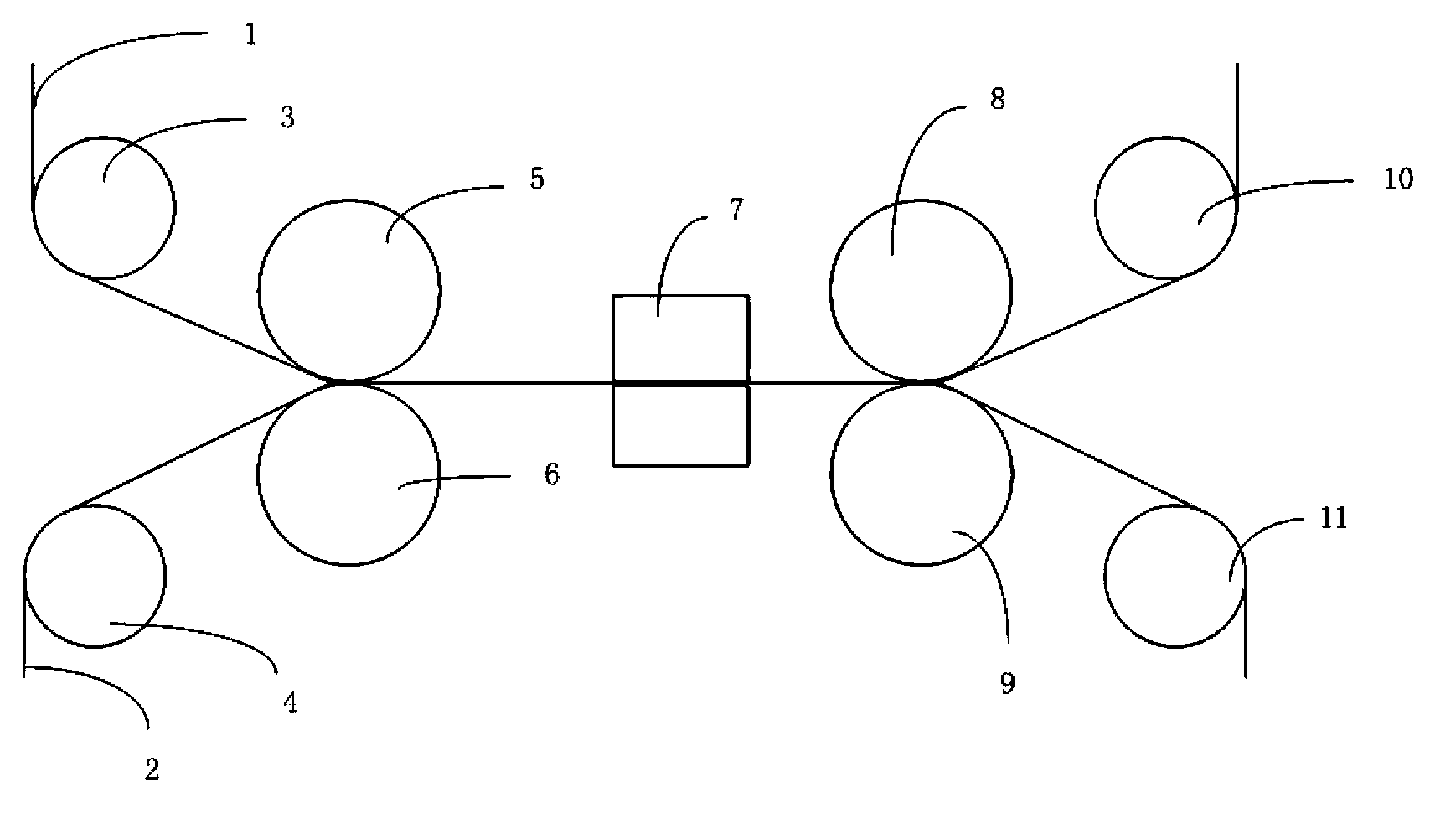

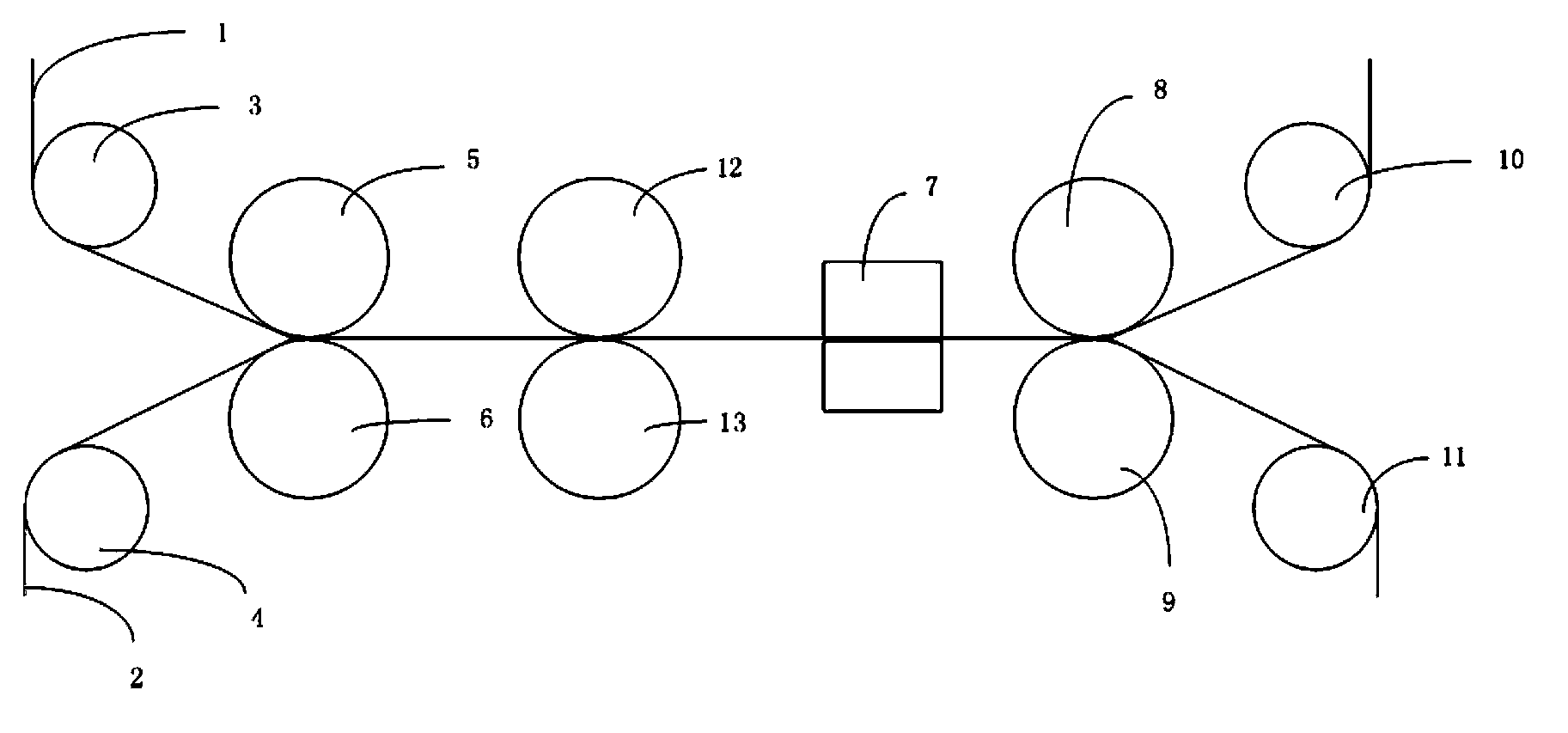

[0011] There are two types of traditional hot stamping machines: flat pressing flat skipping hot stamping machine and round pressing round skipping hot stamping machine. Because both the paper and the hot stamping paper must be stationary when pressing, the flat-press flat stamping machine has low efficiency and slow speed. The general speed is about 30 meters per minute, and the stamping is 5000-10000 stampings, and it is gradually replaced by the round pressing circle. . For circular hot stamping machine, since the paper can move at a constant speed, the hot stamping paper adopts the jumping method to keep the same speed as the paper when pressing, so the speed can be greatly increased, generally 40-60 meters per minute, saving hot stamping Paper, and extremely small vibration, low noise. Hot-melt glue is coated on the side of the hot stamping paper that is in contact with the paper. At a certain temperature, the glue melts and combines with the paper under proper pressure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com